A high-strength refractory brick

A high-strength, brick-laying technology, used in furnaces, lighting and heating equipment, furnace components, etc., to solve problems such as falling blocks, burning through kiln door covers, and peeling castables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

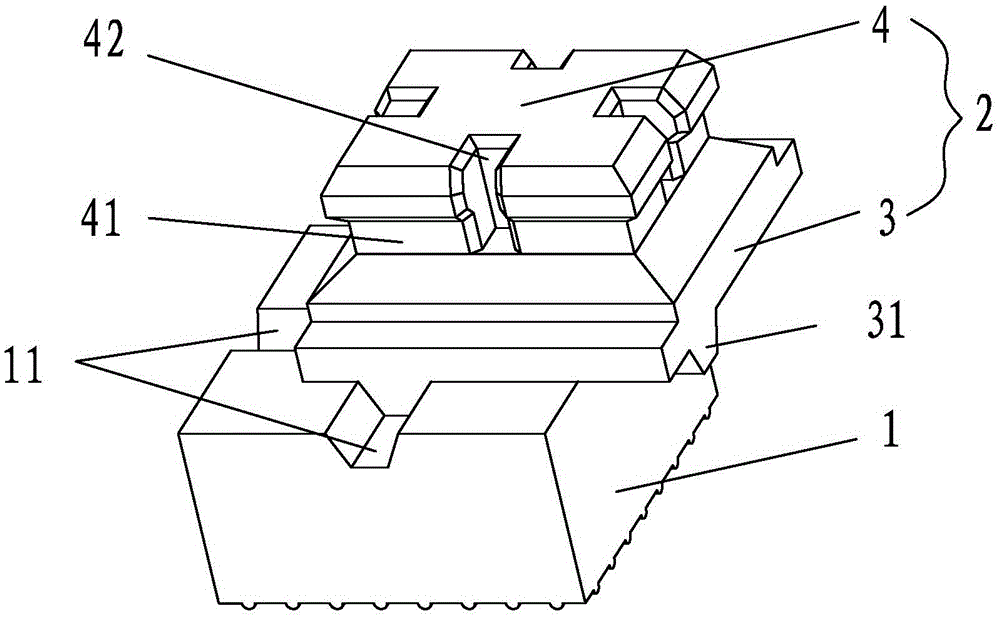

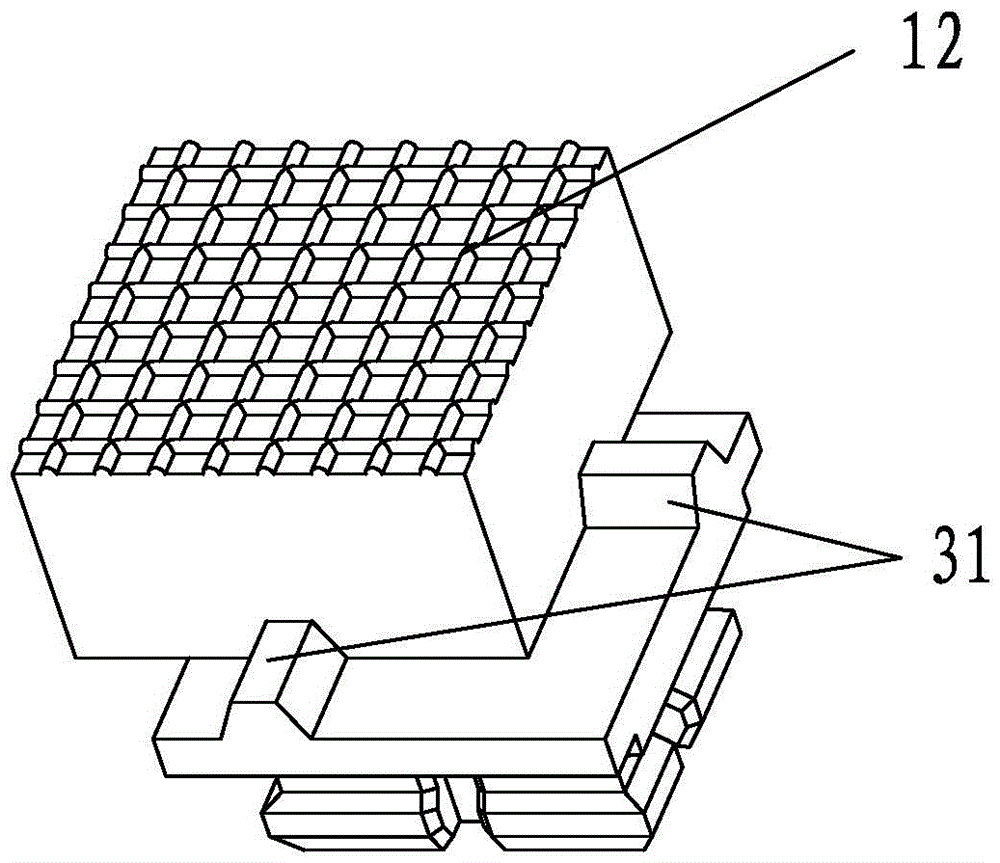

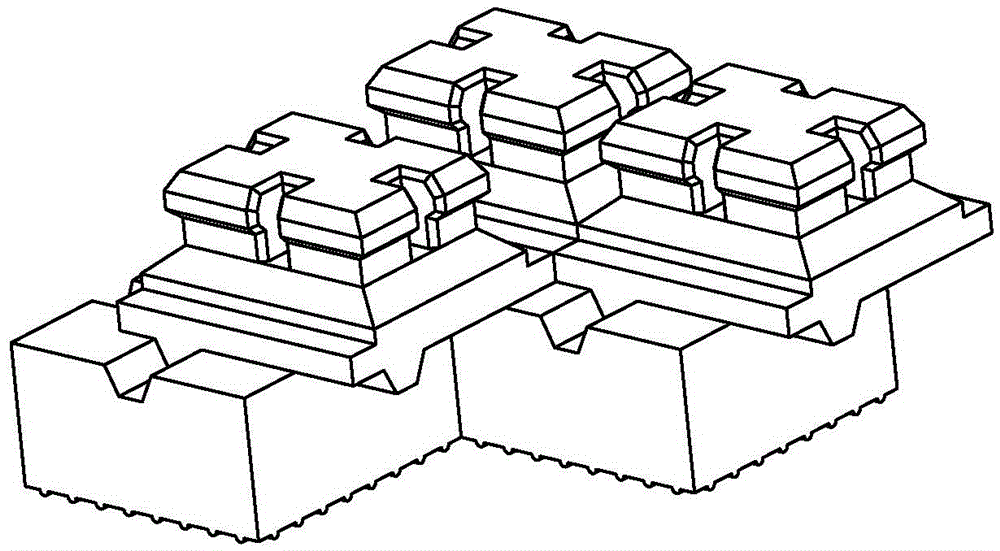

[0017] Such as Figure 1 to Figure 5 Shown, a kind of high-strength refractory bricklaying comprises bricklaying body 1, and bricklaying body is cube, and the top surface of bricklaying body is provided with positioning brick 2, and described positioning brick comprises brick seat 3 and is located on the brick seat Auxiliary brick 4, the external dimensions of the brick base are the same as those of the brick-laying body, the brick base is eccentrically arranged on the brick-laying body, and the left side of the brick base is provided with a distance from the left side of the brick-laying body. The front side of the brick base and the front side of the brick body are also provided with the same spacing, that is, a part of the positioning brick extends out of the brick body, and the bottom surface of the brick base is horizontally and longitudinall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com