Cable electricity leakage detection device

A detection device, a technology for cable leakage, applied in electromagnetic measuring devices, measuring devices, electromagnetic/magnetic thickness measurement, etc., can solve problems such as the inability to accurately control the thickness of the insulating sheath, the inability to achieve the accuracy of inspection, and the degradation of transmission performance. , to achieve the effect of light weight, simple structure and high distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

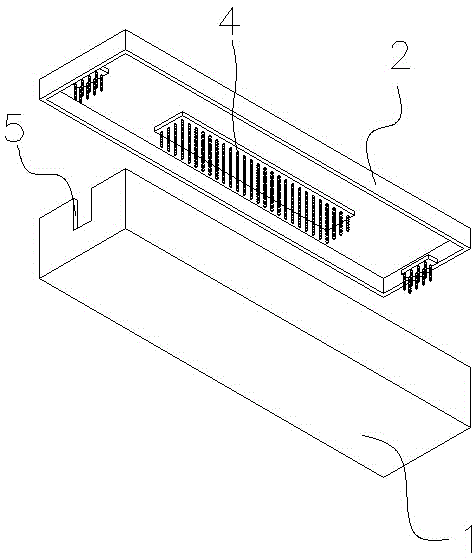

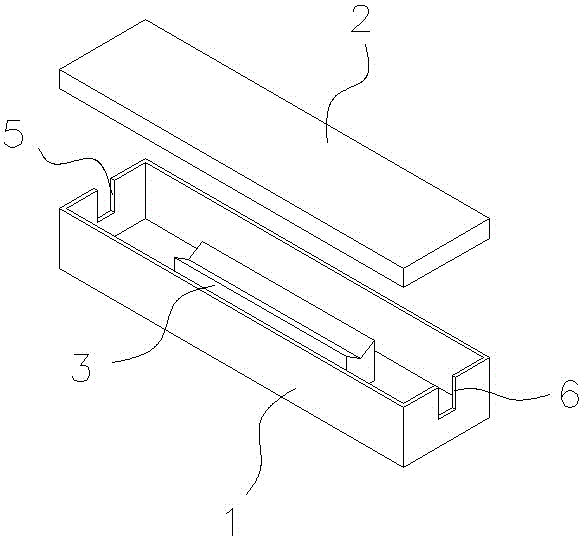

[0024] A cable leakage detection device, comprising a frame, a bearing platform 3 is arranged on the frame, and a detection mechanism is arranged on the bearing platform 3. Contacts that move freely within range; the contacts are small spherical structures made of metal. A plurality of contacts are connected in series to form a plurality of string structures 4 that are electrically connected to each other and cover the carrying surface of the carrying platform 3 . The detection mechanism is also provided with a signal source which is insulated from the contacts and electrically connected with the cable to be tested, and a signal receiver which is electrically connected with the contacts.

[0025] The frame is provided with a hollow shielding cover 1, the shielding cover 1 covers the carrying platform 3 and the contacts, the shielding cover 1 is respectively provided with an inlet 6 and an outlet 5 along the feeding and discharging direction of the carrying platform 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com