Substrate fixing base of concentrating photovoltaic circuit

A circuit substrate fixing and concentrating photovoltaic technology, which is applied in the field of solar photovoltaic power generation, can solve problems such as product yield decline, inconsistency in operation methods, and low production capacity, so as to improve production efficiency, prevent defective or scrapped products, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

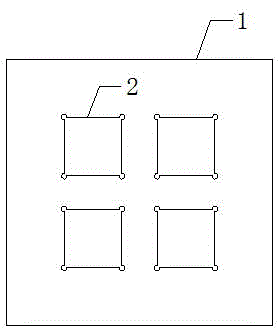

[0013] A fixed base for a concentrated photovoltaic circuit substrate, such as figure 1 As shown, it includes base 1 and CPV circuit substrate

[0014] The groove 2 is characterized in that the base 1 is engraved with a concentrating photovoltaic circuit substrate groove 2, the base 1 is made of high temperature resistant material, the thickness is greater than 10mm, and the upper and lower surfaces are flat, and there must be no damage: engrave the base 1 There are concentrating photovoltaic circuit substrate grooves 2 neatly arranged, and the edges of the concentrating photovoltaic circuit substrate groove 2 must be smooth and flat without any burr.

[0015] For specific applications, see figure 1 First, fix the fixed base of the concentrating photovoltaic circuit substrate on the printing platform, place the concentrating photovoltaic circuit substrate in slot 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com