Method and device for adjusting fiber feed to carding machine

A feeding device and fiber feeding technology, applied in fiber feeding, fiber treatment, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

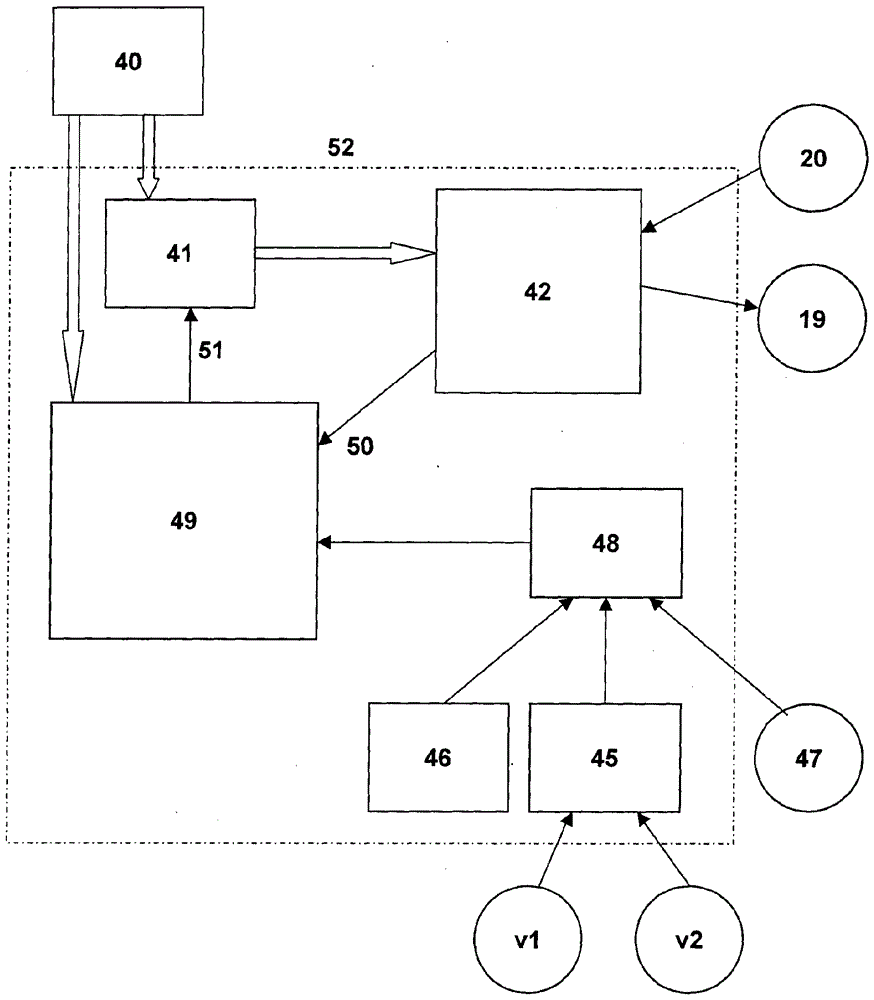

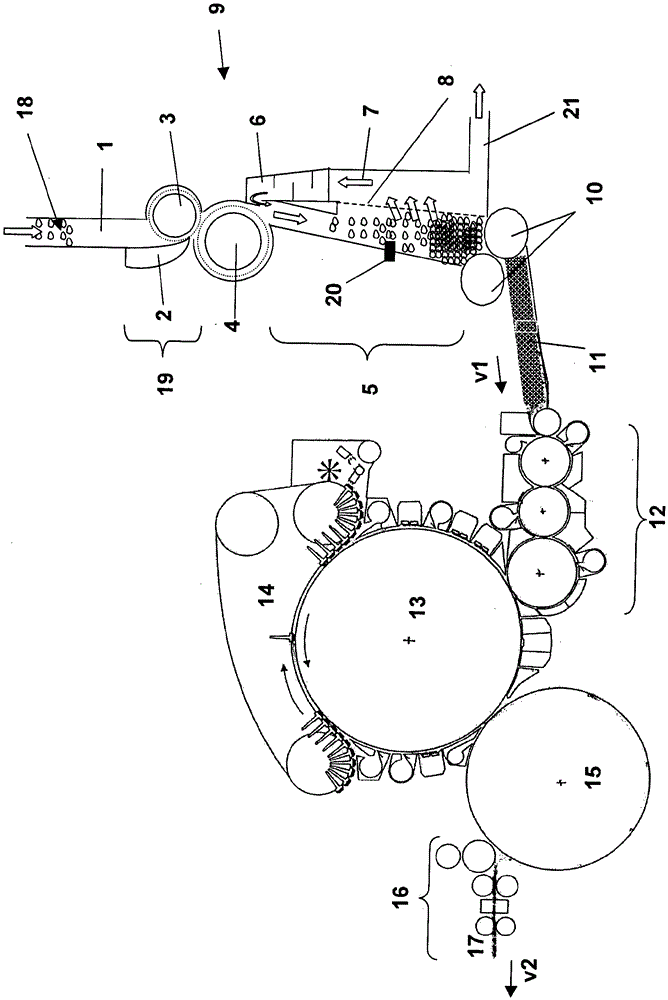

[0018] figure 1 A rotary flat card equipped with a feed box 9 is shown. After the fiber tow 18 has passed through the various process stages of the blowroom system, it enters the upper box 1 of the feeding box 9 . The fiber bundle 18 is transferred by a feed device 19 comprising a feed trough 2 and a feed roller 3 to the opening roller 4 , which further opens the fiber bundle 18 . The opening roller 4 transports the further opened fiber bundle 18 into the lower cotton box 5 . This opening roller 4 does not have to be present to ensure the adjustment of the batt weight, but the presence of said opening roller and the resulting fine opening of the fiber bundle does affect the compaction of the fiber bundle, while the pressure in the lower box 5 remains the same . A pressure sensor 20 for measuring the prevailing pressure is arranged in the lower hopper 5 . A blowing device 6 is provided in the cotton feeding box 9 for further compacting the batt. The blowing device blows mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com