Cooling water circulation system of reaction kettle

A circulation system and cooling water technology, applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem of affecting reaction time, high heat, and heating time long wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

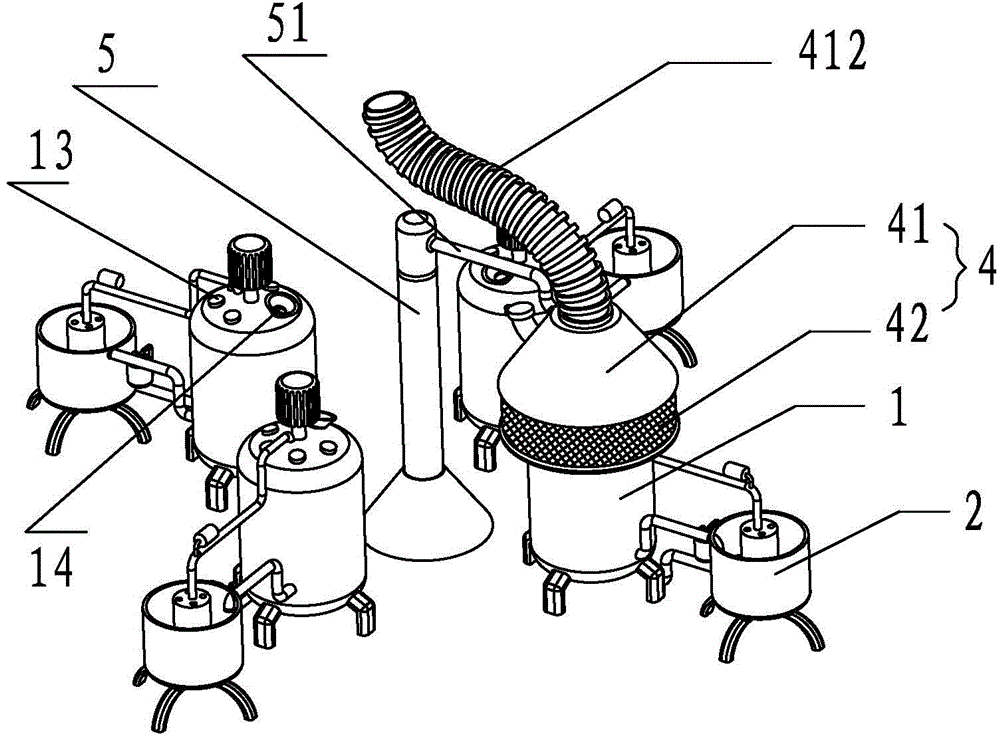

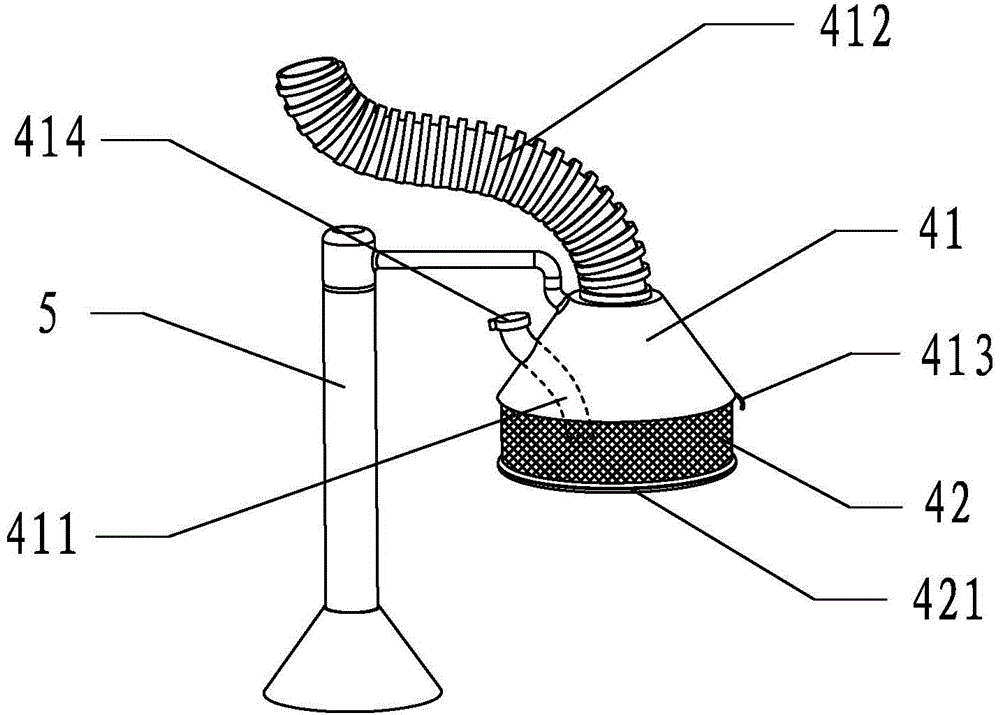

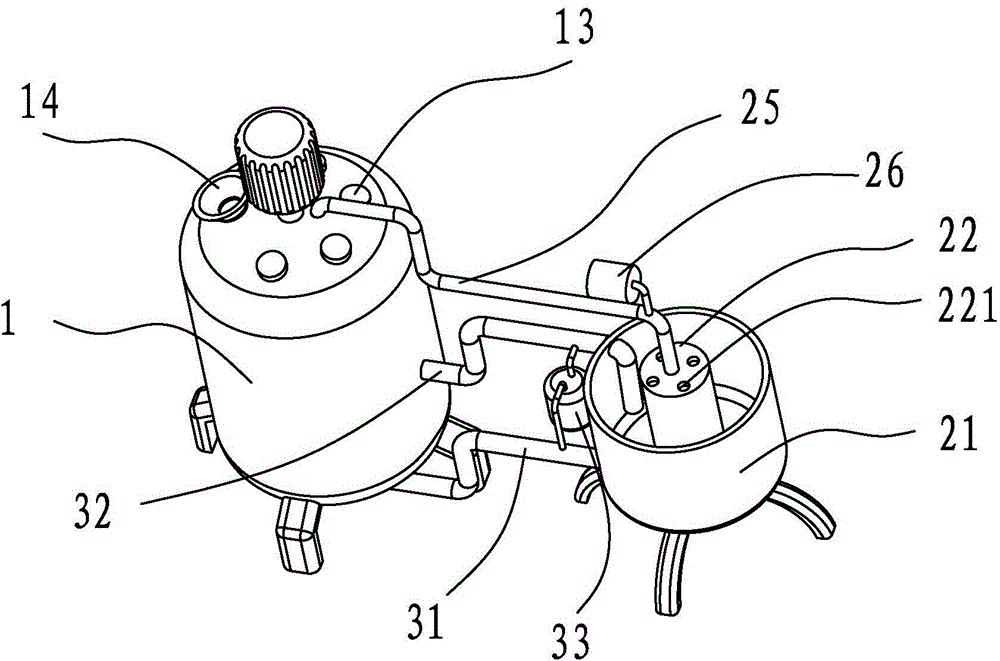

[0021] Such as Figure 1 to Figure 4 As shown, the top of the reactor main body 1 is provided with an exhaust port 13 and a feed port 14, the exhaust port is used to discharge the gas in the reaction process, and the feed port is used to add the materials used for the reaction into the reactor. The main body of the reactor is provided with a reaction liner 11, and there are at least two of the main body of the reactor, and a column 5 is arranged outside the main body of the reactor, and more than one connecting rod 51 is hinged on the top of the column, and the connecting rod can be centered on the column. Rotate, the end of the connecting rod is fixed with an exhaust hood 4, and the exhaust hood is sleeved on the top of the reactor main body. In this example, there are 4 reactor main bodies in a cross-shaped layout, and the column Placed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com