Patents

Literature

50results about How to "No industrial waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

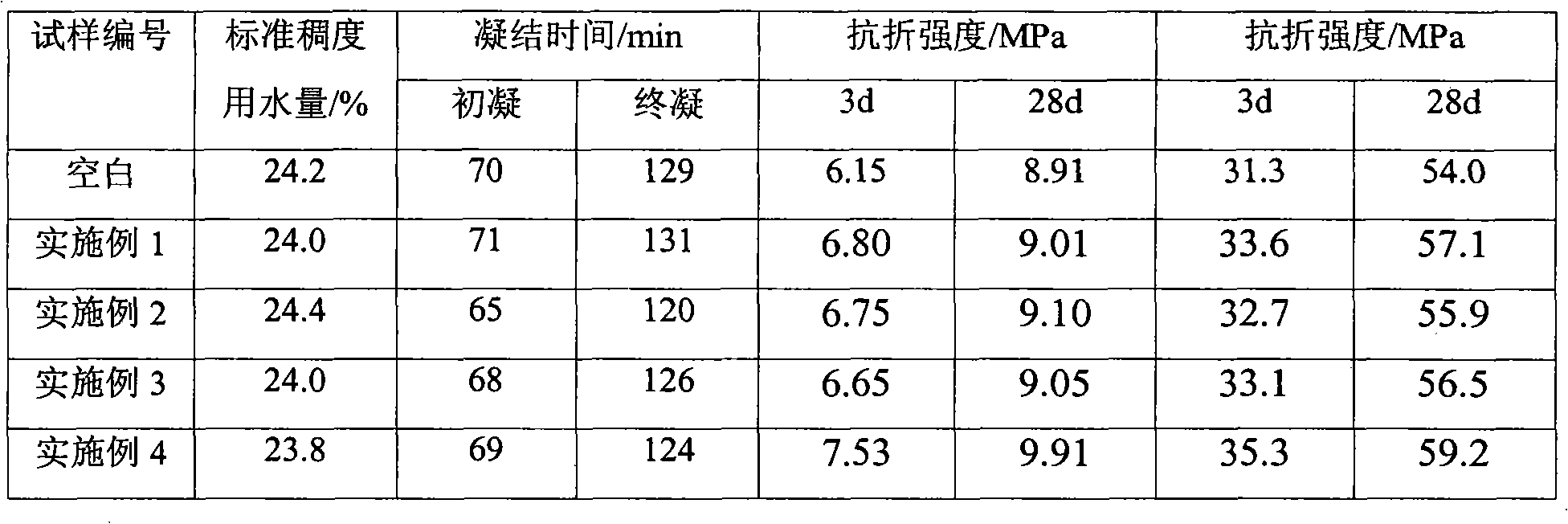

Polycarboxylate cement grinding aid and preparation method thereof

The invention discloses a polycarboxylate cement grinding aid and a preparation method thereof. The preparation method comprises the following steps of: performing copolymerization on comonomers in aqueous solution in the presence of an initiator to obtain a polymer A, wherein the comonomers comprise ether monomers, amine monomers and carboxylic acid monomers; and adding a small amount of alcamines substance B into the polymer A to obtain the polycarboxylate cement grinding aid. The grinding aid has the advantages of obviously improving grinding efficiency and greatly improving cement strength, along with simple production method and environmental protection.

Owner:安徽海螺材料科技股份有限公司

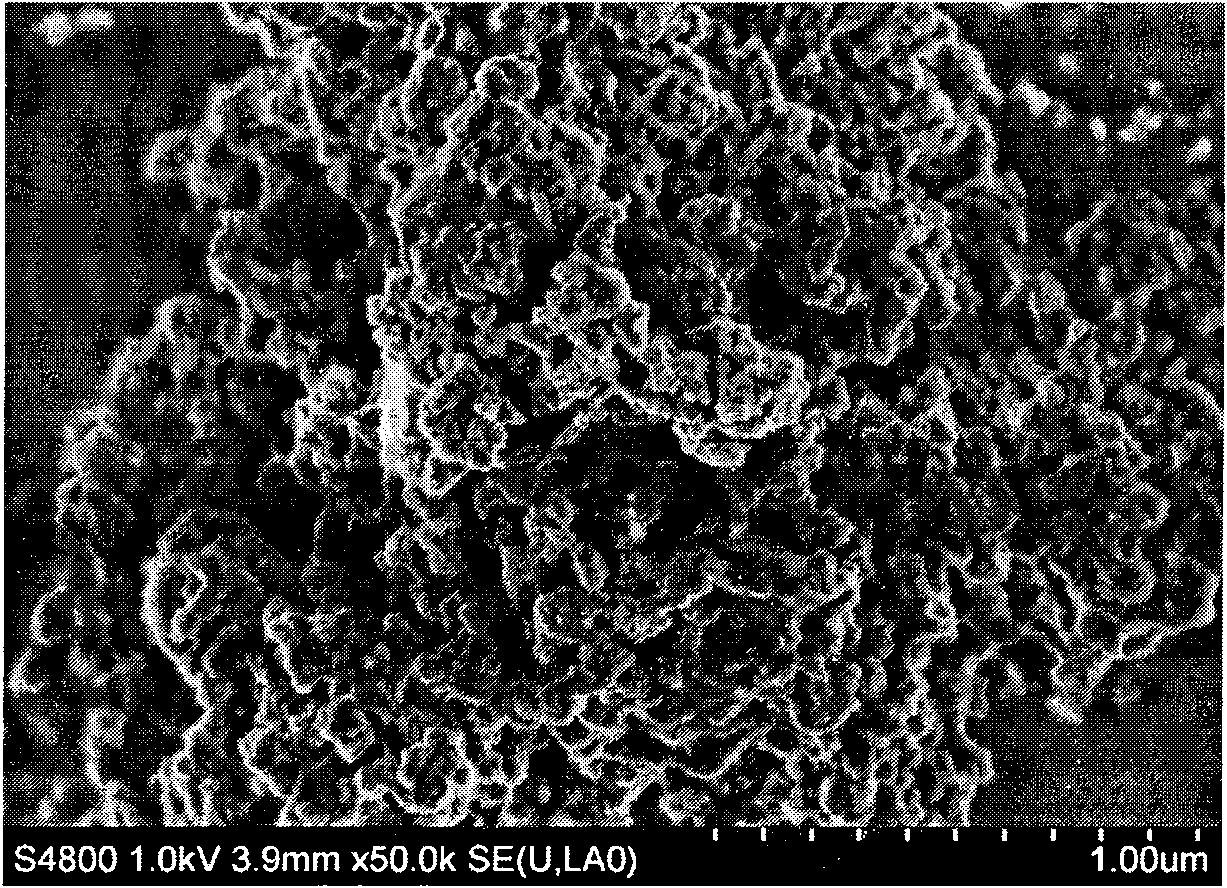

Treatment method for effectively improving microstructures and absorption properties of attapulgite and kieselguhr

InactiveCN103084152AGood dispersionHigh porosityOther chemical processesWater/sewage treatment by sorptionPorosityPhysical chemistry

The invention discloses a treatment method for effectively improving microstructures and absorption properties of attapulgite and kieselguhr. By using high-temperature pyrolysis, sputtering and Coulomb explosion effect generated by physical irradiation, a nanorod crystal structure inside the attapulgite is effectively decomposed and dispersed, and the specific surface area of the attapulgite is increased, and thus the absorption property of the attapulgite can be remarkably improved. Meanwhile, impurities in ducts of the kieselguhr can be removed, the porosity is increased, and thus the absorption property is improved. The modified clay can be used as a pesticide adhering assistant and an efficient absorbing agent for use.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

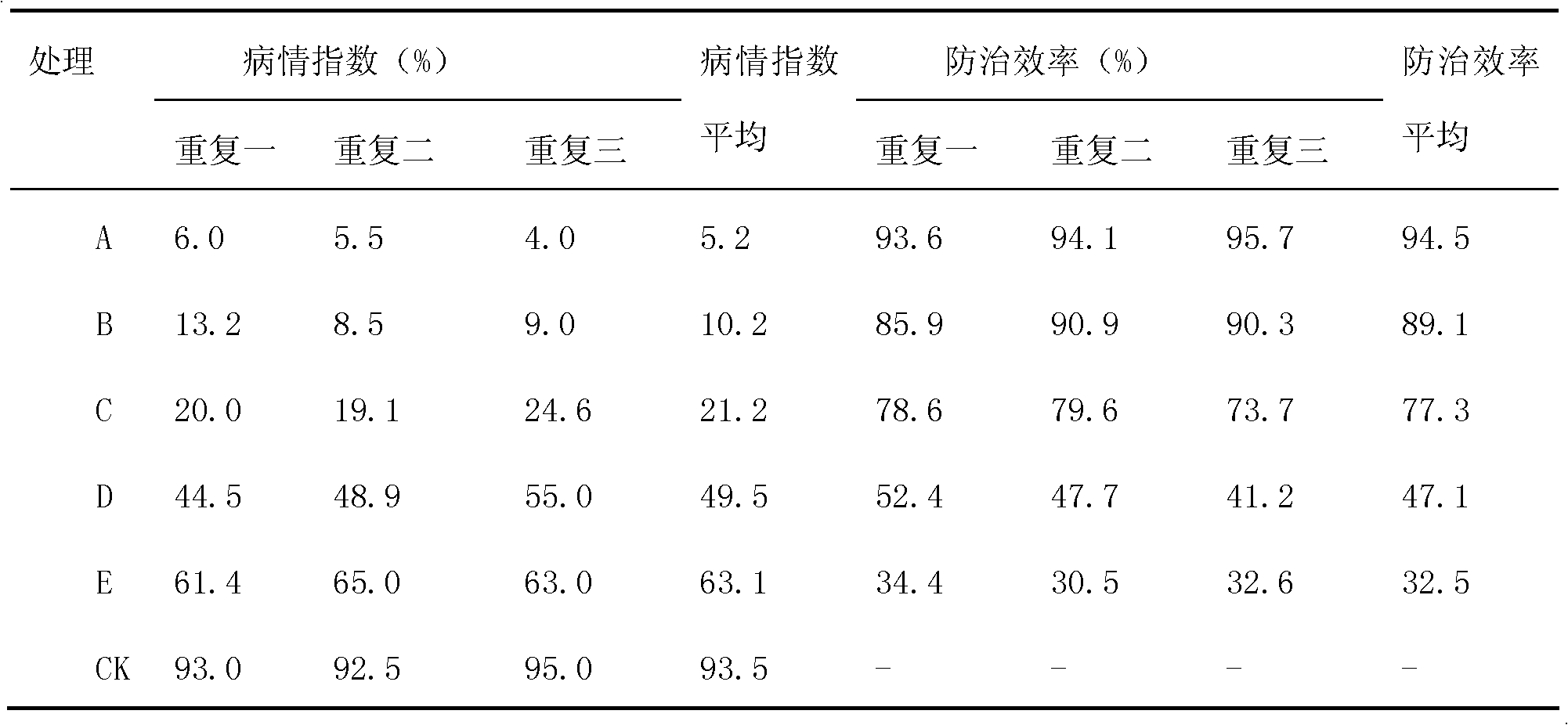

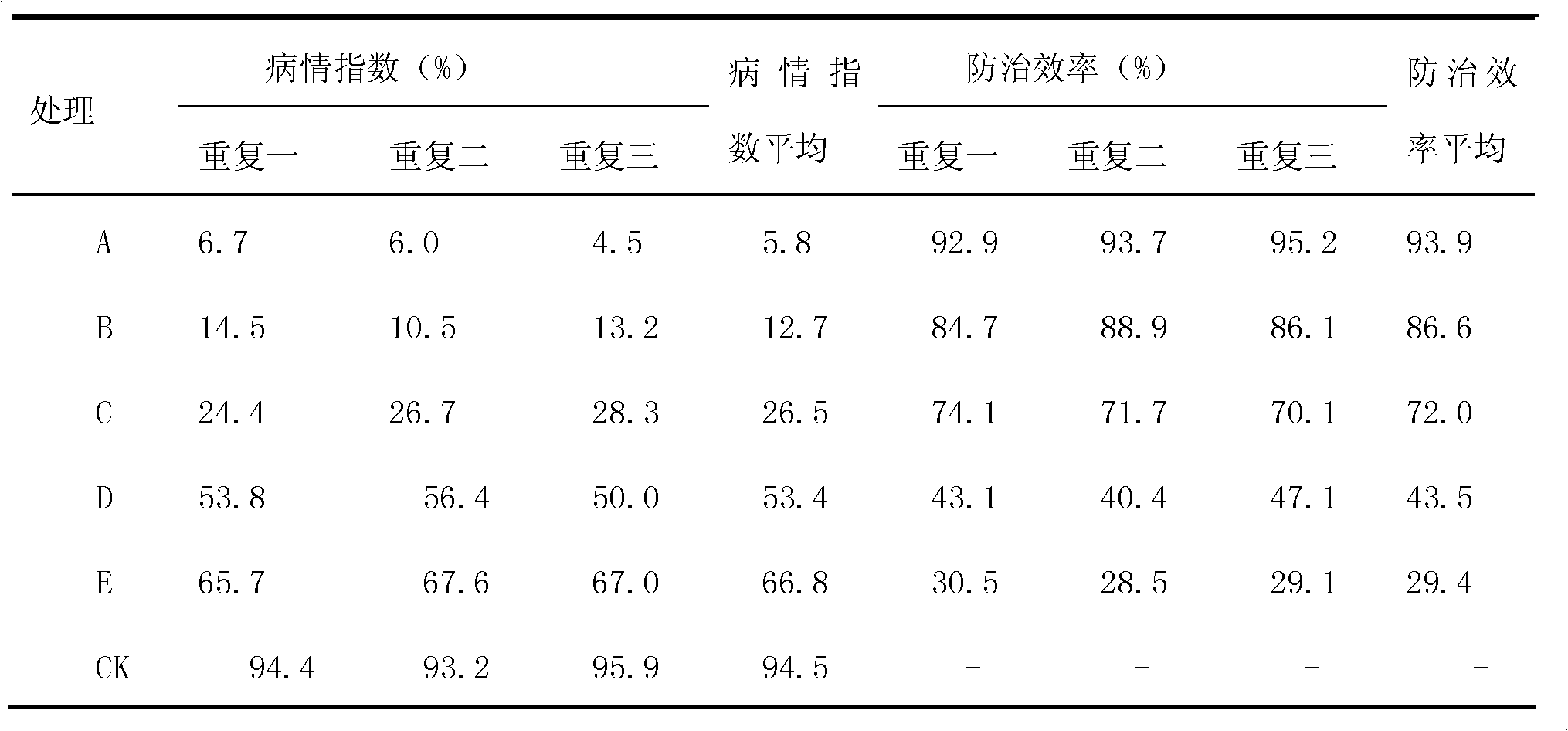

Bacillus subtilis and use thereof in bio-control preparation for preventing and controlling powdery mildew

InactiveCN102250814APromote healingEase of industrial productionBiocideBacteriaBiotechnologyNicotiana tabacum

The invention discloses bacillus subtilis and use thereof in bio-control preparation for preventing and controlling powdery mildew and belongs to the field of microbial pesticides. The strain is (bacillus subtilis)FBR1 with a collection number of CGMCC No.4915. The industrial fermentation culture medium for the bacillus subtilis is prepared from 0.8 percent of corn flour, 1.5 percent of soybean flour, 0.1 percent of yeast powder, 0.5 percent of peptone, 0.8 percent of monopotassium phosphate, 0.15 percent of calcium carbonate, 0.02 percent of magnesium sulfate and 0.001 percent of defoamer, and by the steps of adjusting the pH value to 7.0, fixing volume by using water, and fermenting for 24 to 36 hours under conditions of a fermentation temperature of 28 to 35 DEG C, a ventilation volumeof 0.2 to 0.4 v / v / min and a stirring speed of 100 to 150r / min. The invention also discloses a bio-control preparation which contains bacillus subtilis and can be used for preventing and controlling powdery mildew in economic crops such as melons, vegetables, tobacco and strawberry in place of spray chemical medicines without polluting the environment.

Owner:滨州国虹生物科技有限公司

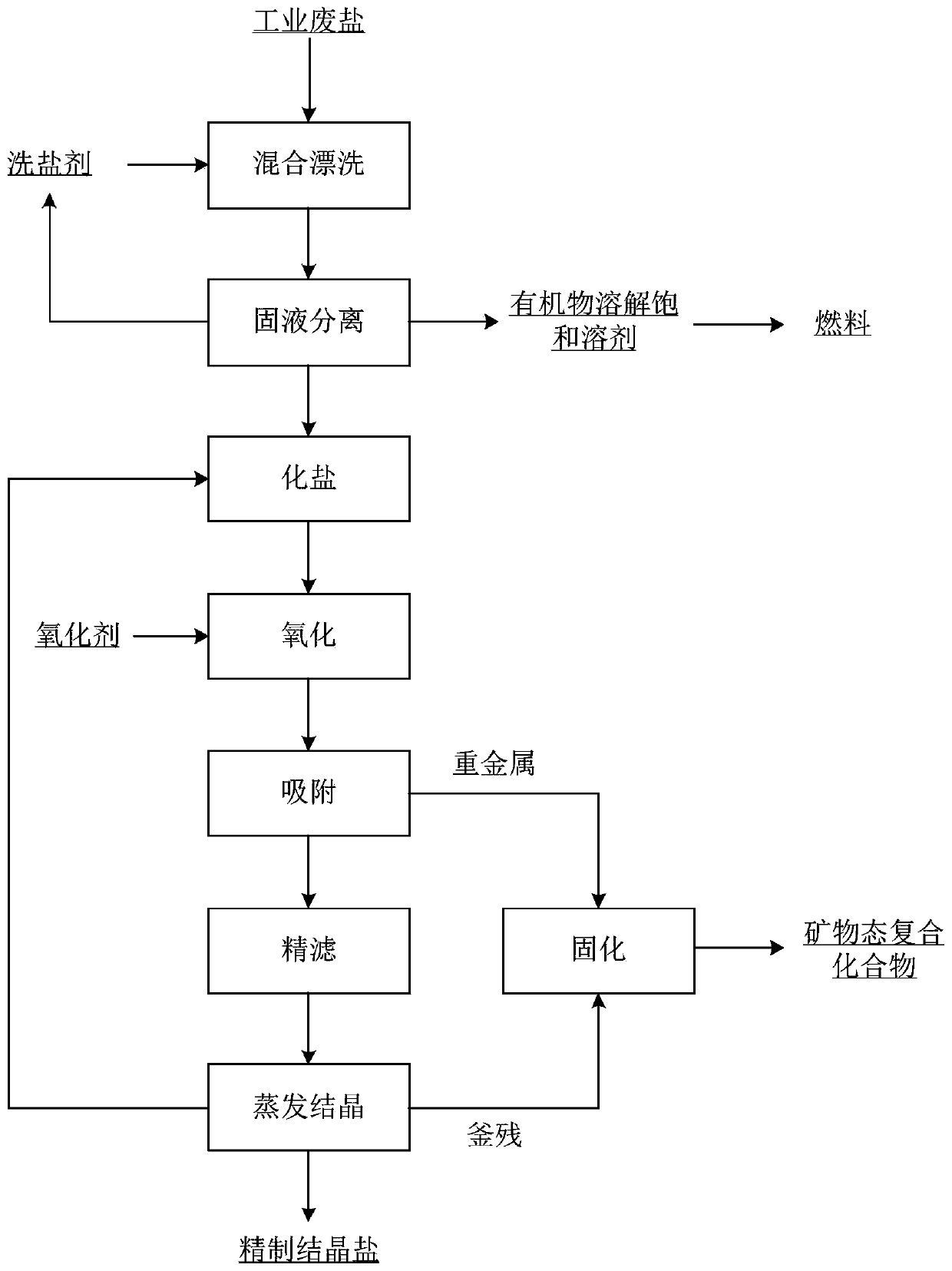

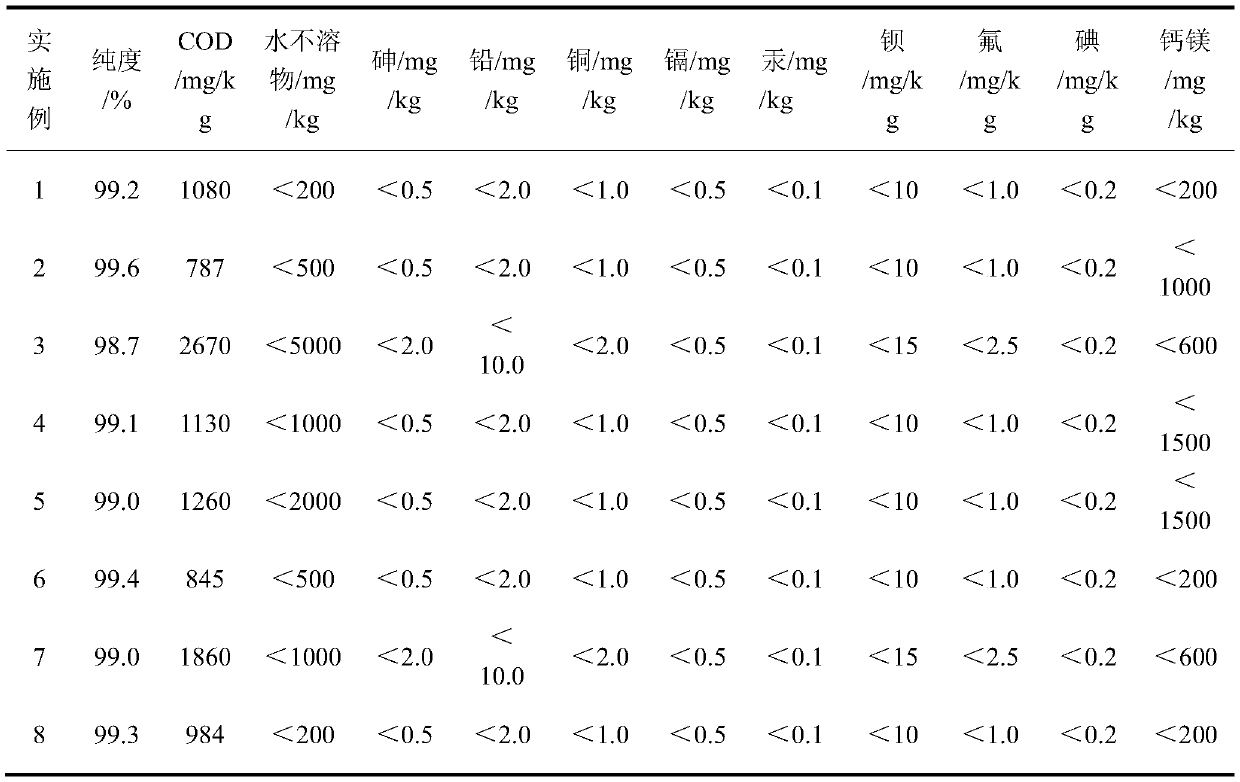

Method for refining industrial waste salt

InactiveCN110642270AAchieve refinementMaximize resource utilizationAlkali metal sulfite/sulfate purificationAlkali metal halide purificationFiltrationProcess engineering

The invention relates to a method for refining an industrial waste salt. The method comprises the following steps: the industrial waste salt is mixed and preprocessed with a salt leaching agent, and then solid-liquid separation is carried out to obtain a preprocessed salt and a filtrate; the preprocessed salt is subjected to salt dissolving, and then is oxidized to obtain a primary treatment liquid; and the primary treatment liquid is adsorbed and finely filtered, and then is crystallized to obtain a refined crystallized salt. The method realizes effective separation of organic matters and salt in the waste salt, ensures effective separation and removal of the organic matters in the industrial waste salt and adsorption and fine filtration removal of other impurities in the industrial wastesalt, and realizes the refining of the high-quality crystallized salt. The method has the advantages of simple process, low energy consumption, low cost and mild conditions, does not produce industrial three wastes in the treatment process, and is an environmentally-friendly salt refining technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

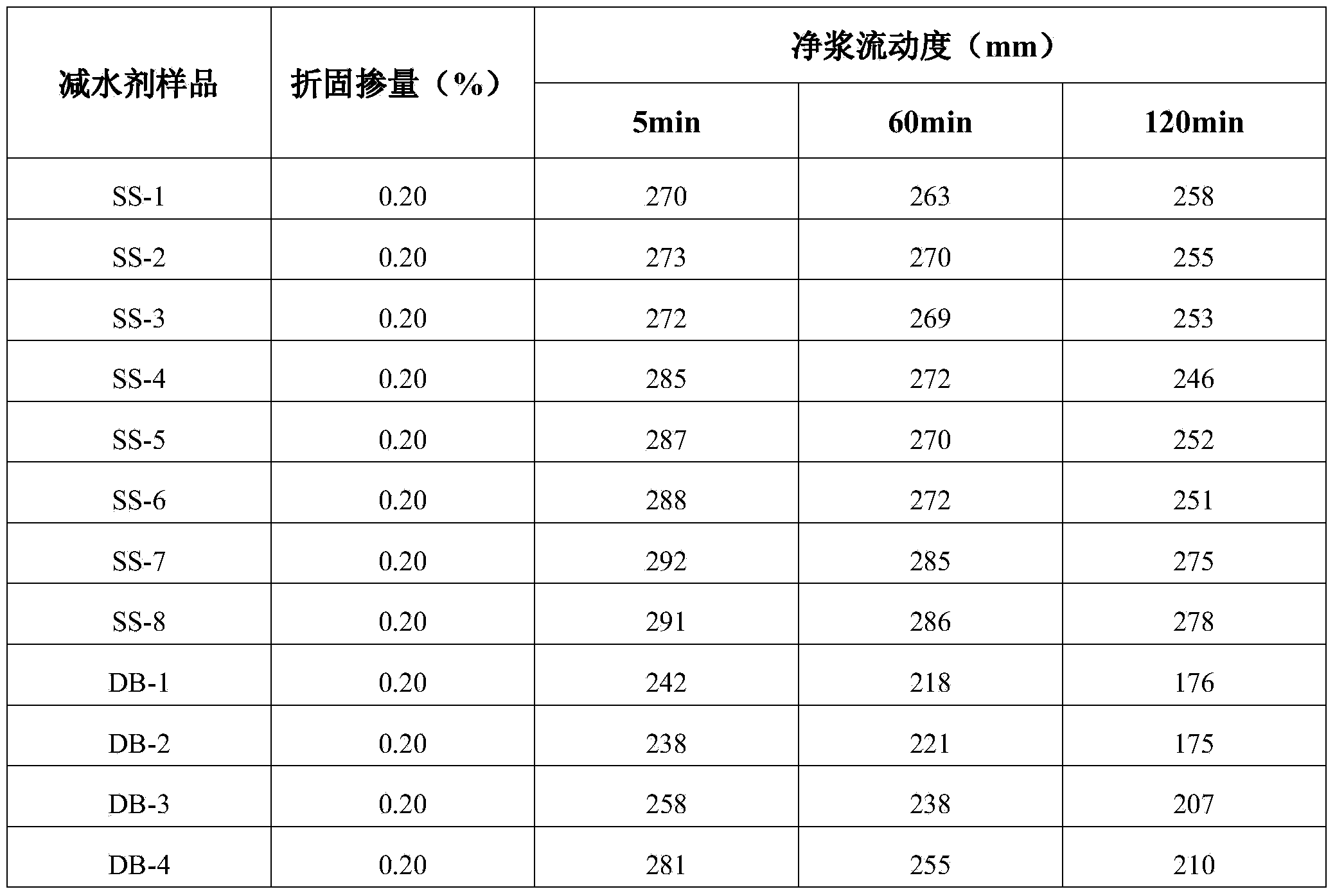

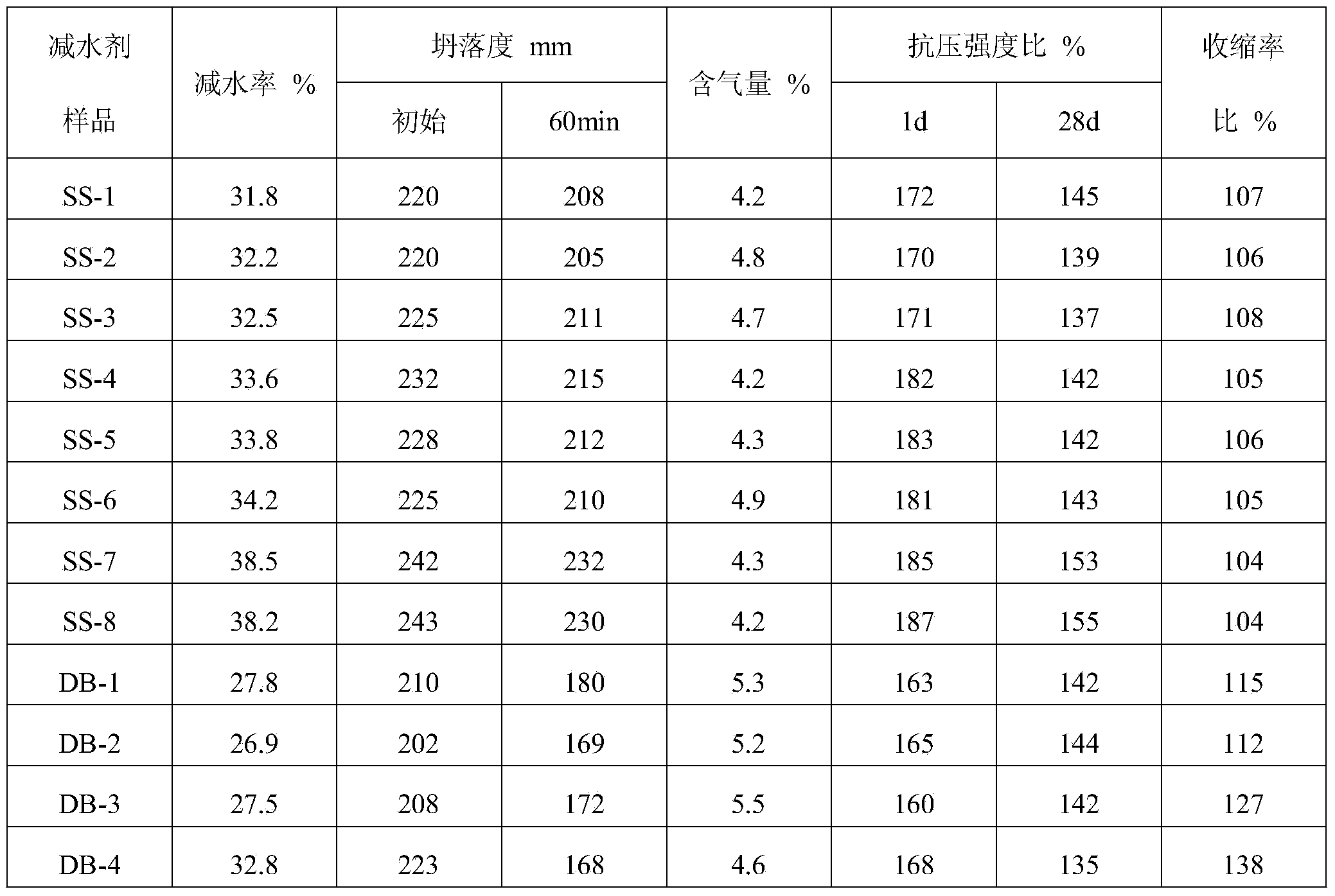

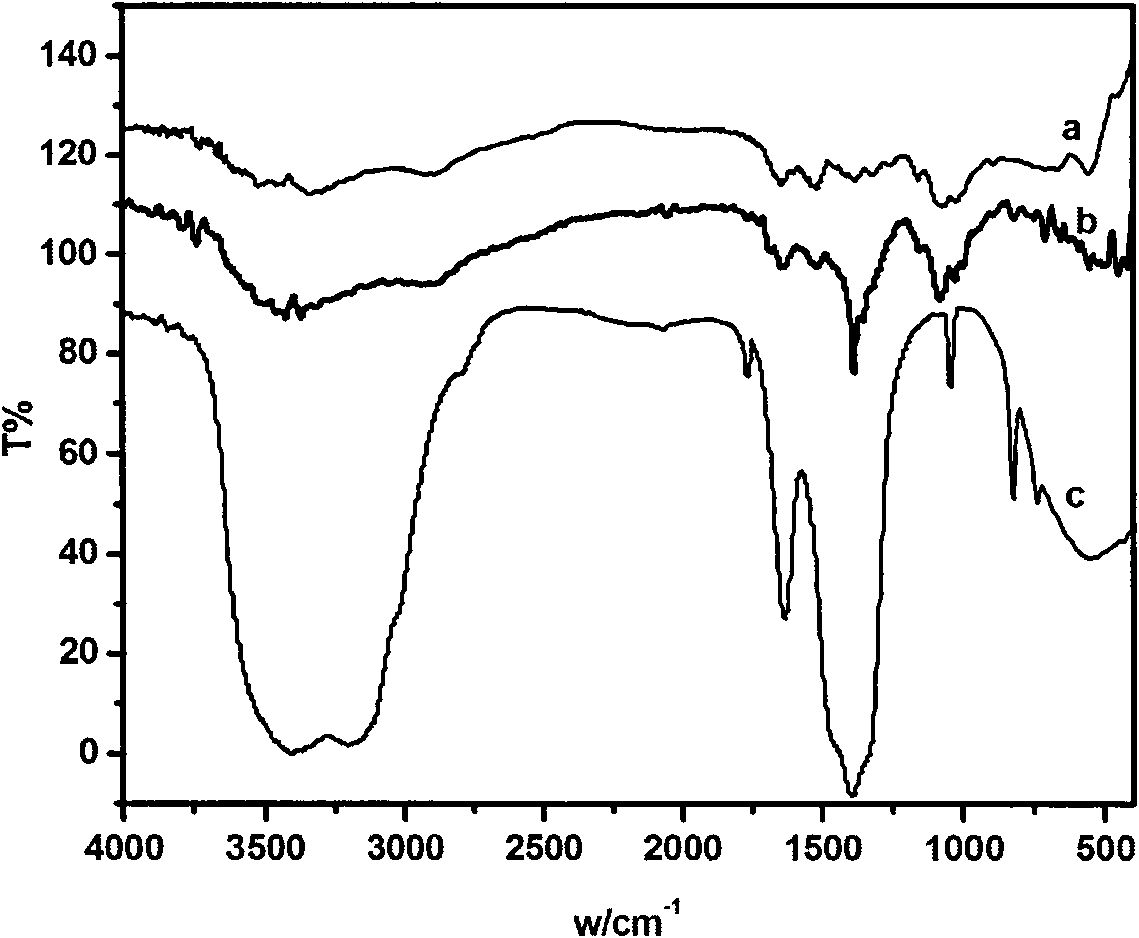

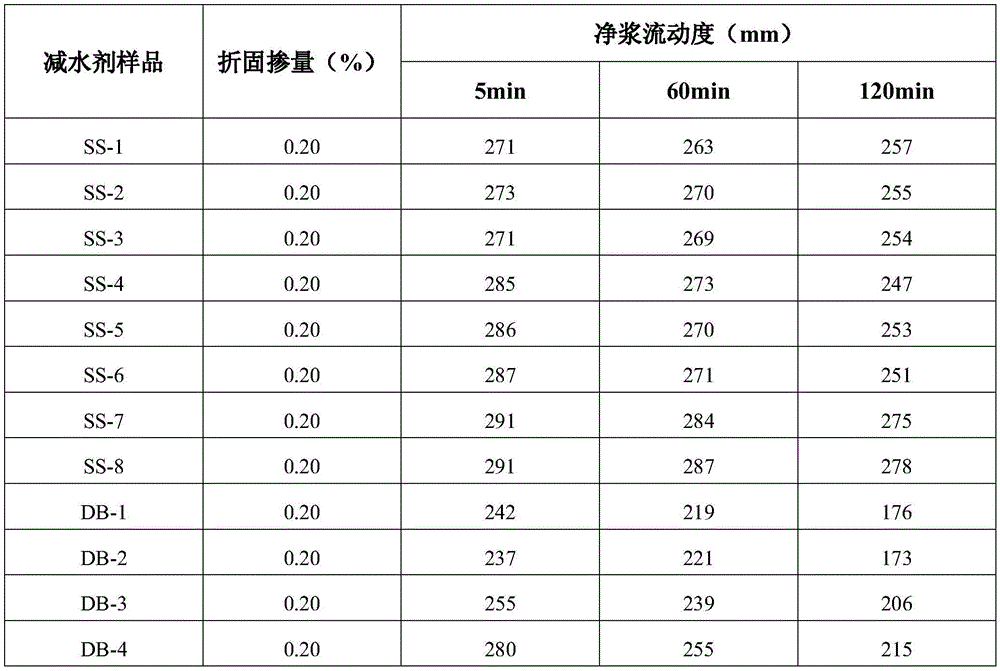

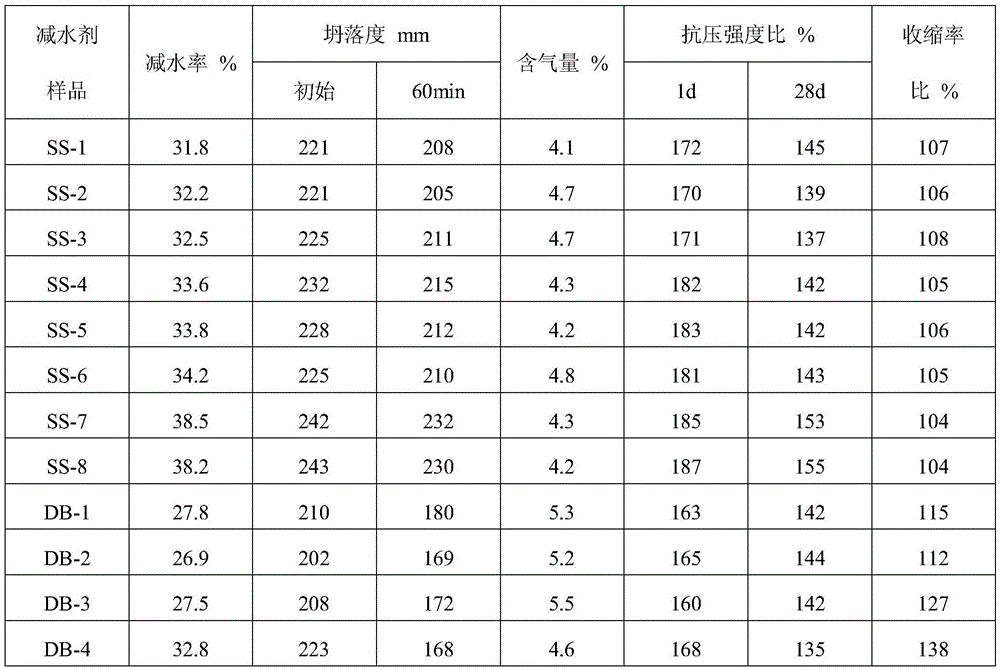

Double long branch-chain polycarboxylic acid water reducing agent and preparation process thereof

InactiveCN101905960AThe process is simple and easy to controlNo industrial wasteAmmonium sulfateAcid water

The invention discloses a double long branch-chain polycarboxylic acid water reducing agent and a preparation process thereof. The water reducing agent is copolymerized from methoxypolyethylene glycol methyl acrylate, polyethylene glycol monomethyl acrylate, methacrylic acid and 2-acrylamide-2 methyl propyl sodium sulfonate by using ammonium persulfate as an initiator. The preparation process comprises the following steps of: dissolving the four monomers into water to form dropping solution 1, and dissolving the ammonium persulfate into water to form dropping solution 2; adding the water into four flasks provided with a thermometer, a stirrer, a dropping funnel and a condenser, and heating the water to 80 DEG C; dropping the dropping solution 1 and the dropping solution 2 into the flasks at the same time, keeping the constant temperature of between 80 and 90 DEG C after the dropping is finished, and reacting the solution for 4 to 15 hours; and after the reaction is finished, neutralizing the solution by using sodium hydroxide till the pH is 7 to 9 so as to obtain the water reducing agent solution. By substituting a part of polyether for methoxyl polyester, the branch chains in the molecular structure of the water reducing agent have high density, the two long branch chains have better synergistic steric effect, the water reducing rate of the water reducing agent is higher, the slump loss of concrete is lower and the water reducing agent has stronger adaptability to cement.

Owner:湖北鑫汇生物科技有限公司

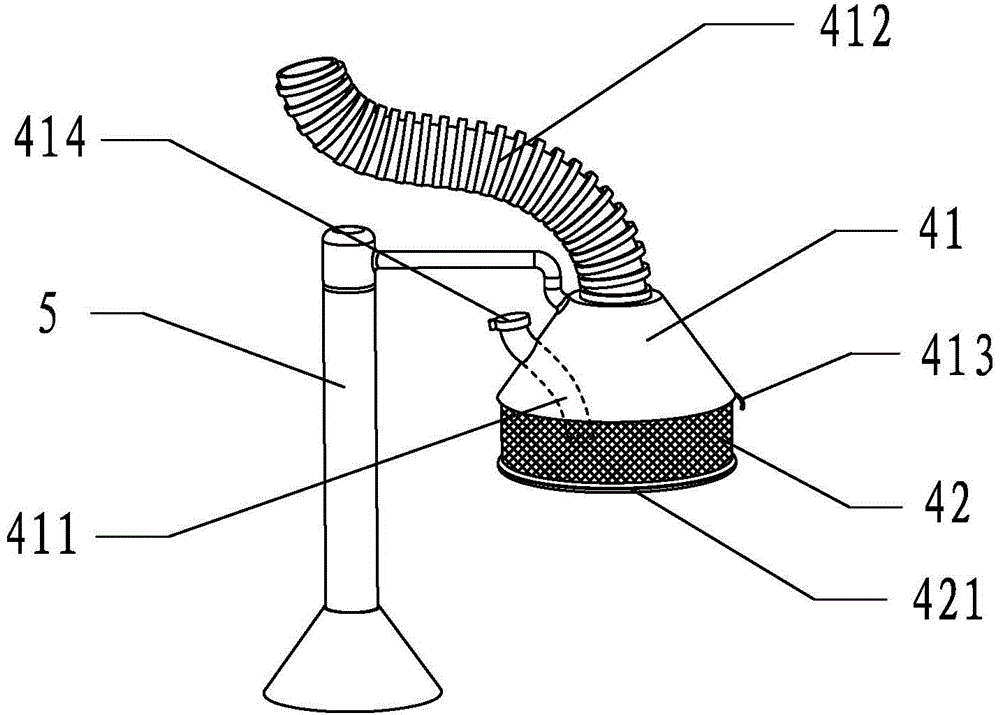

Process for dyeing cloth by using spraying method

InactiveCN101775719AReduce manufacturing costPut an end to the disadvantages of color matchingTextile treatment machine partsTextile treatment by spraying/projectingState of artWastewater

The invention relates to a process for dyeing cloth by using a spraying method, belonging to the field of dyeing or printing of textile fabrics. The process is characterized by comprising the following steps of: blending various colors needed by cloth dyeing in advance by adopting computer program control and using a program control dyeing machine on which a dye cell is arranged; taking one section of cloth and placing the cloth on a special track in the program control dyeing machine; starting the program control dyeing machine, and spraying the blended dye on the surface of the cloth by a spray head on the program control dyeing machine; after the dyeing procedure, leading the cloth to continue to go forwards along the special track and then enter a drying cylinder for drying under high temperature, and finishing the cloth dyeing process. Compared with the prior art, the invention adopts the spraying dyeing process to dye cloth and greatly reduces the production cost. Due to the adoption of the computer program control, the color of the dye is constant, cloth in the same batch has the same color, and the defect that color matching is performed depending on the experience of a color matching expert is avoided. In the whole spraying dyeing process, no waste water and waste gas are generated, thereby the process is green and environment friendly.

Owner:张伟

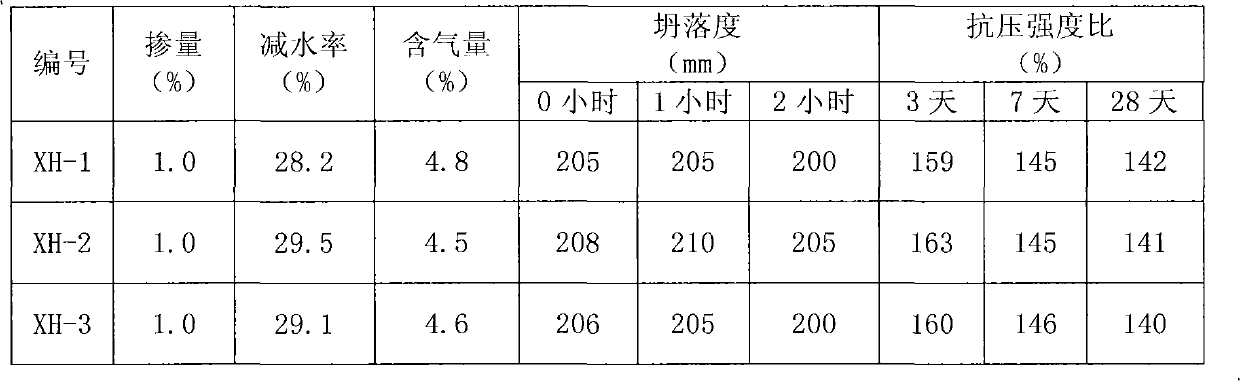

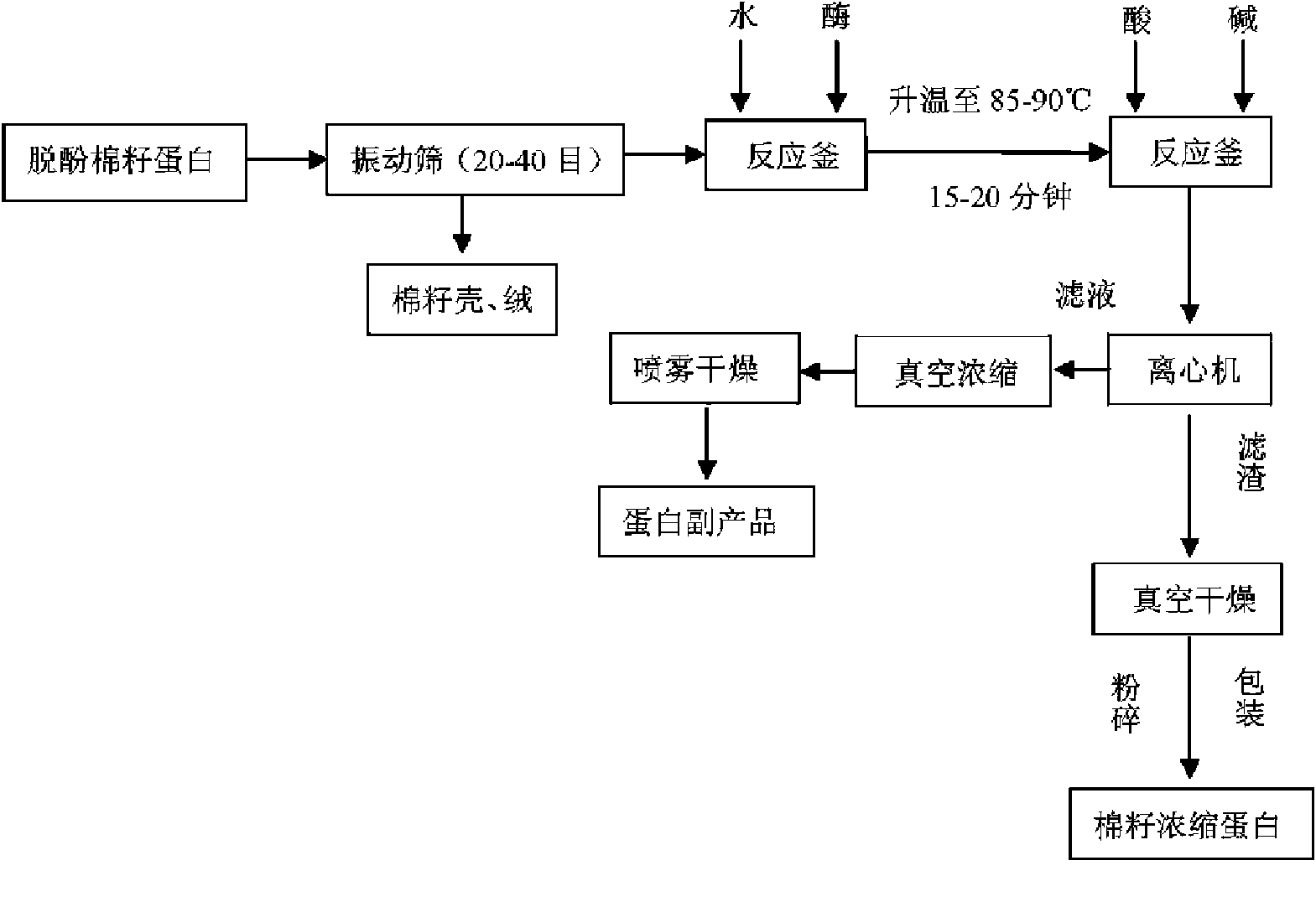

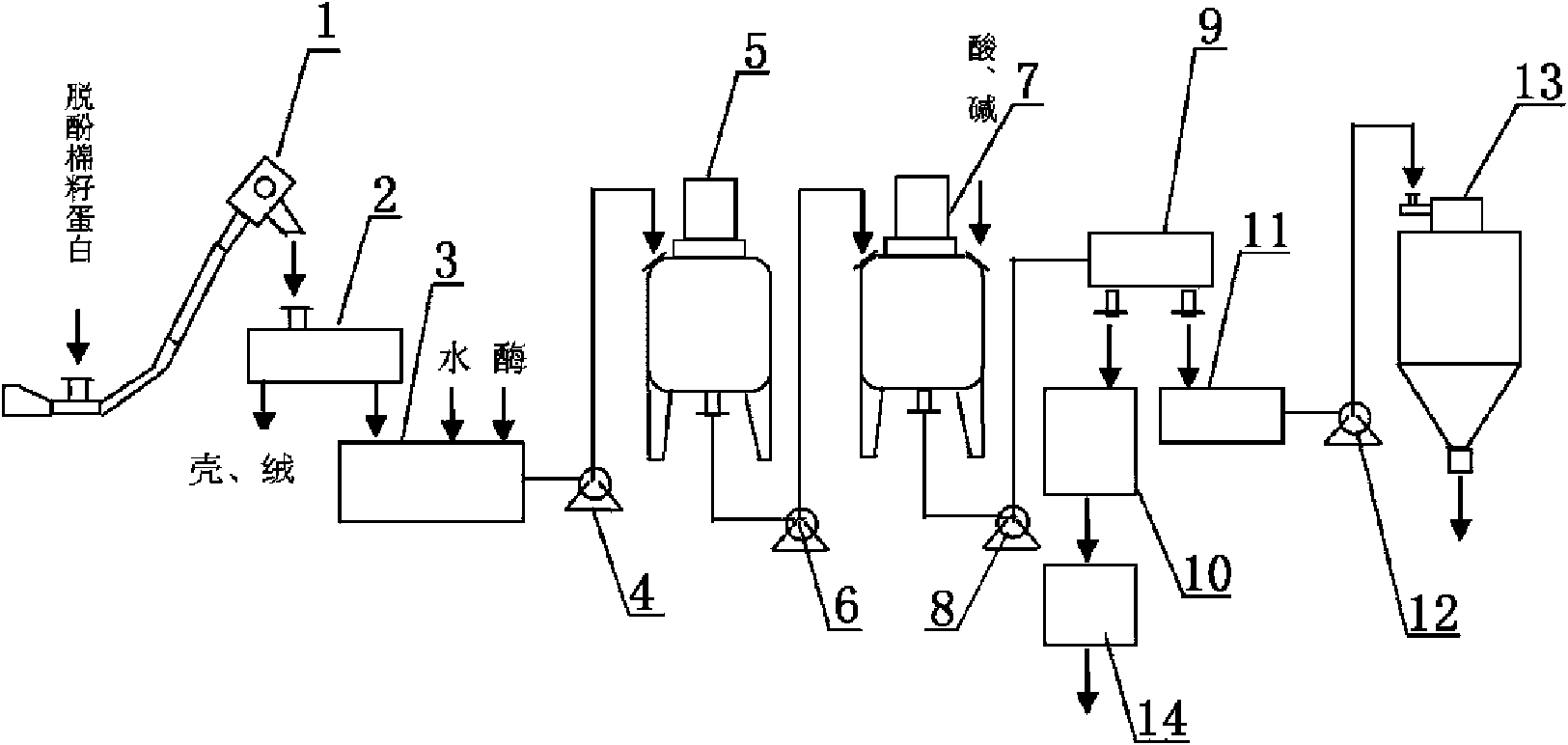

Preparation method of concentrated protein of cottonseeds and processing production line thereof

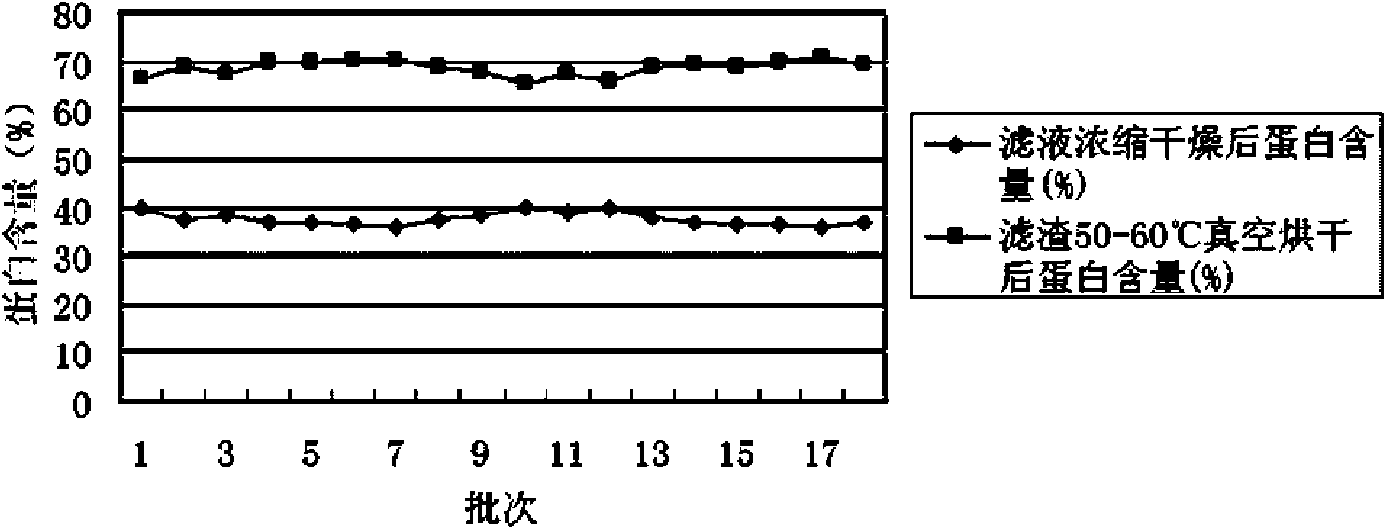

InactiveCN101665534ASimple preparation processConducive to environmental protectionPeptide preparation methodsPlant peptidesProtein contentIndustrial waste

The invention relates to a preparation method of concentrated protein of cottonseeds and a processing production line thereof, which comprise the following steps: carrying out shell and flocking removal to dephenolized cottonseed protein raw material by a sieve of 20-40 meshes, dissolving the raw material in 6-8 times of water, adding amylase, cellulase and pectinase which respectively account for0.5-0.6 per thousand, 1.0-1.2 per thousand and 0.4-0.5 per thousand in the raw material by mass at the temperature of 30-40 DEG C for 1-3h, inactivating enzyme for 15-20min after temperature is risento 85-90 DEG C; after temperature reduction, adjusting the pH value to 4.0-4.5 by hydrochloric acid and the like for 1-1.5h, and then adjusting the pH valve to be neutral by using NaOH or Ca(OH)2 for1-1.5h; separating materials in a centrifugal machine (filter cloth of 80-100 meshes): conducing spray drying after the filtering liquid is concentrated to 1 / 5-1 / 4 volume in vacuum, thus obtaining secondary product (with 35-40% of protein content); and grinding a filter cake after drying in vacuum, thus obtaining the concentrated protein product of cottonseeds (with 65-70% of protein content). Inthe invention, the technology is simple and has no three industrial wastes.

Owner:中发麦迪尔生物科技江苏有限公司

Long-chain polycarboxylic acid water reducing agent

The invention relates to a long-chain polycarboxylic acid water reducing agent which is prepared by adopting ammonium persulfate as an initiator and copolymerizing monomers of allyl polyethylene glycol, polyethylene glycol monomethyl ether methacrylate, acrylic acid and acrylamide, wherein allyl polyethylene glycol accounts for 30-50% of the total monomer mass, polyethylene glycol monomethyl ether methacrylate accounts for 5-20% of the total monomer mass, acrylic acid accounts for 20-40% of the total monomer mass, acrylamide accounts for 1-10% of the total monomer mass, and ammonium persulfate accounts for 2.5-10.0% of the total monomer mass. The preparation of the polycarboxylic acid water reducing agent adopts the free radical polymerization method, takes water as a solvent, has simple and easily controlled process, and has no industrial three wastes; and moreover, the product has excellent properties, has the advantages of low mixing amount, high water reducing rate, small slump degree loss, and strong adaptability to cement, and substantially improves early and later strength of concrete.

Owner:RIZHAO PORT GRP LANSHAN PORT

Rare earth-chitosan oligosaccharide complex and preparation method and application thereof

InactiveCN101633702AGood chemical stabilityImprove thermal stabilityOrganic active ingredientsHeavy metal active ingredientsSolubilityCancer cell

The invention discloses a rare earth-chitosan oligosaccharide complex, in particular to a binary complex formed by the coordination of rare earth ions and chitosan oligosaccharide; the complex is nanoparticles, the average particle size of the particles is 50-100nm, and the particles are distributed evenly. The final concentration of the complex for prompting the apoptosis of K562 cancer cells is 0.001mu g / mL-10mu g / mL, the inhibition ratio of 1mu g / mL of the complex to K562 cancer cells can reach 47% and the complex can be used to prepare the anti-K562 cancer cell drug. Compared with the prior art, the rare earth-chitosan oligosaccharide complex has good water-solubility, low toxicity and high bioavailability, the antitumor activity of the complex is better than any single ligand, the complex has synergetic effect, good chemical stability and good thermal stability, the complex can be used, stored and transported at room temperature; in addition, the preparation method of the invention has the advantage of simple operation, wide raw material sources, green and environmentally friend and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

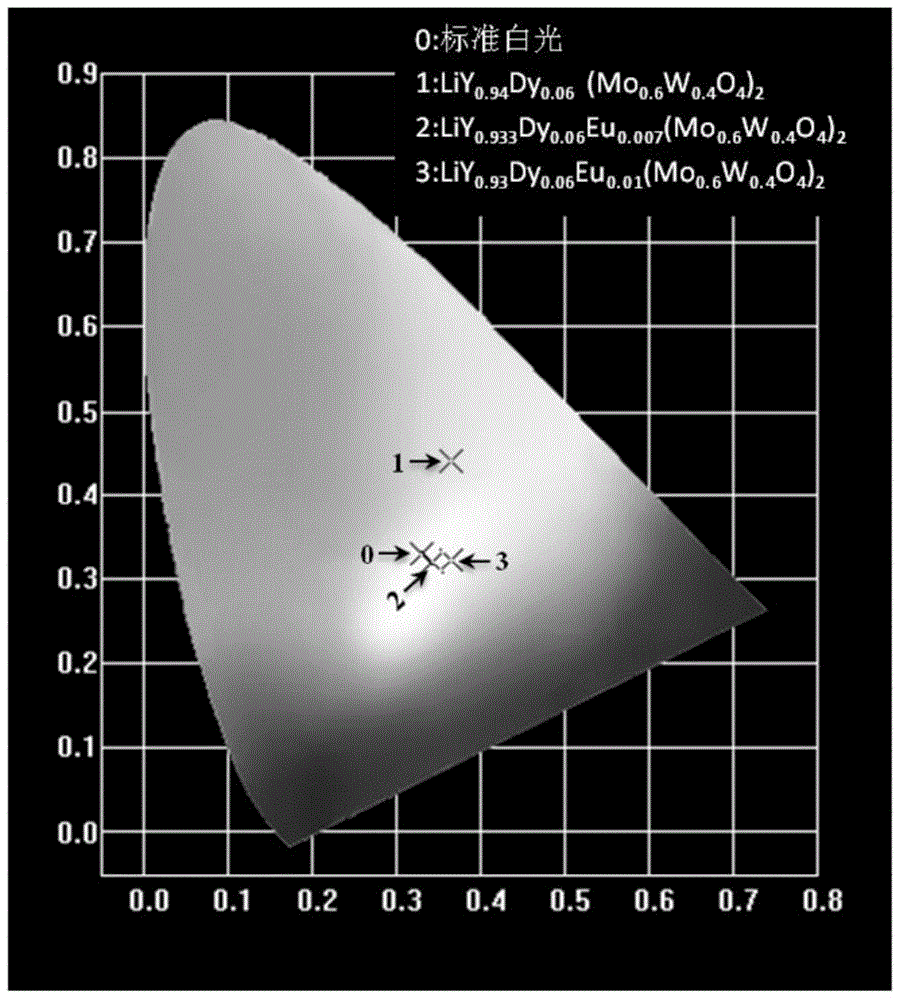

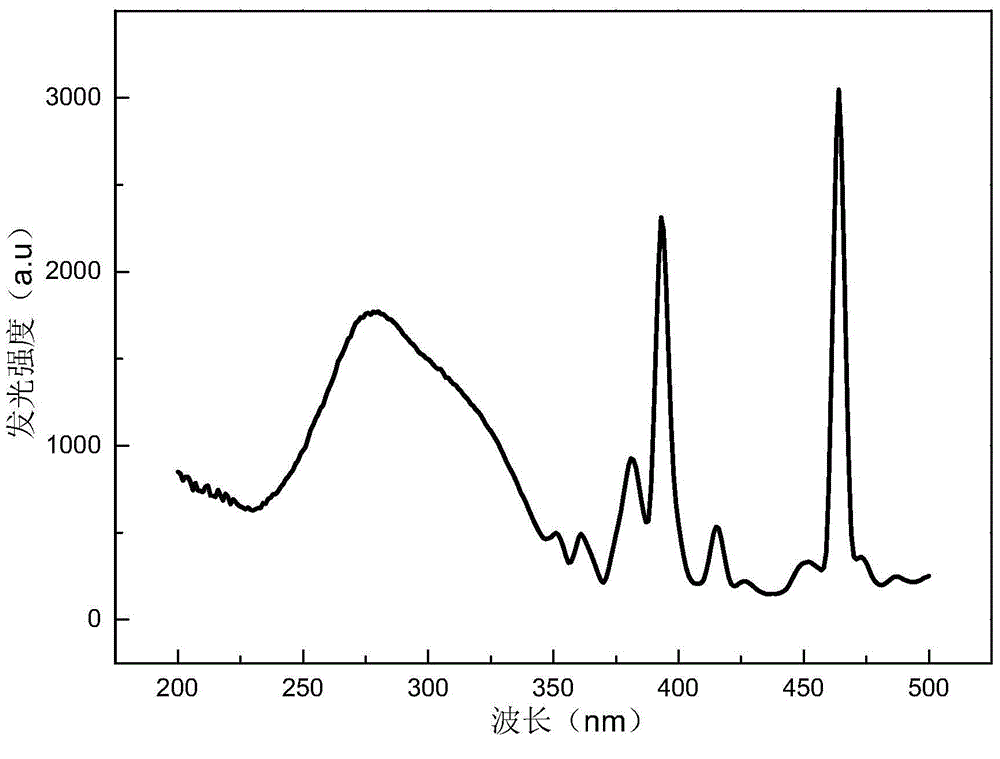

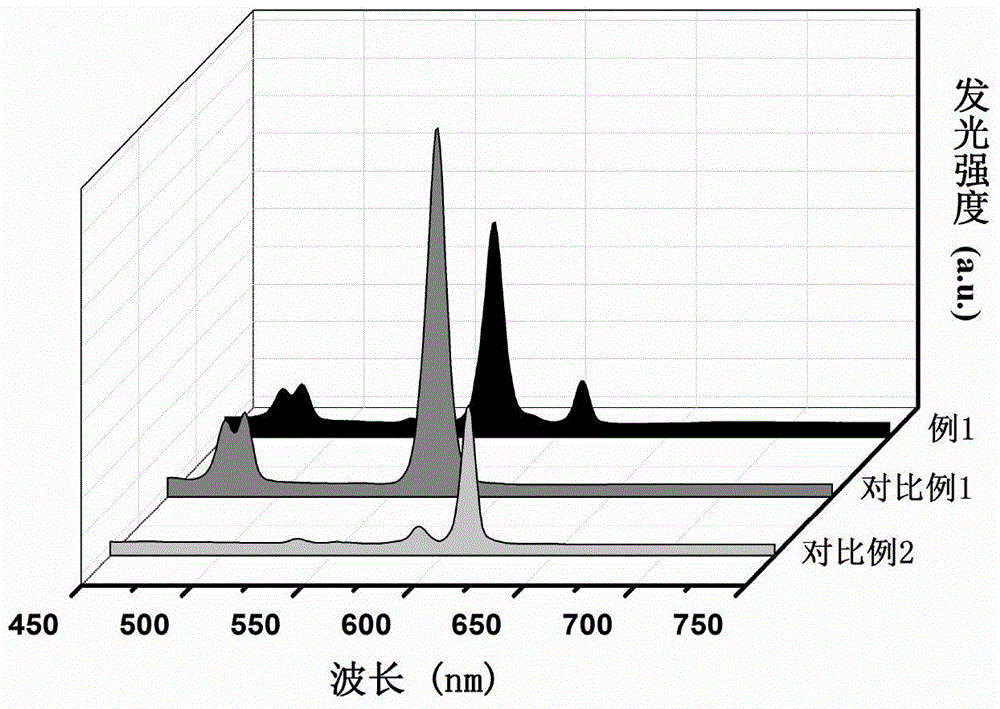

White-light fluorescent powder and preparation method thereof and white light-emitting device

InactiveCN104877680AGood chemical stabilityHigh color rendering indexEnergy efficient lightingLuminescent compositionsNear ultravioletLight-emitting diode

The invention provides white-light fluorescent powder. A chemical formula of the white-light fluorescent powder is AY1-xLnx(Mo1-yWyO4)2, wherein A is one or more of Li, Na and K; Ln is multiple of Tm, Tb, Sm, Eu and Dy, but Eu and Dy can be included; the value range of x is that x is smaller than 1 and greater than 0; the value range of y is that y is smaller than 0.5 and greater than 0; the fluorescent powder can be directly stimulated by a near-ultraviolet LED (light-emitting diode) chip to obtain white light with excellent color purity; an assistant of other fluorescent powder is not needed; and the defects of single-phase white-light fluorescent powder in an existing luminescent material can be overcome. The invention further provides a preparation method of the white-light fluorescent powder. The preparation method is simple and low in production cost, and can be popularized and applied. In addition, the invention further provides application of the white-light fluorescent powder in preparation of white light-emitting devices.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

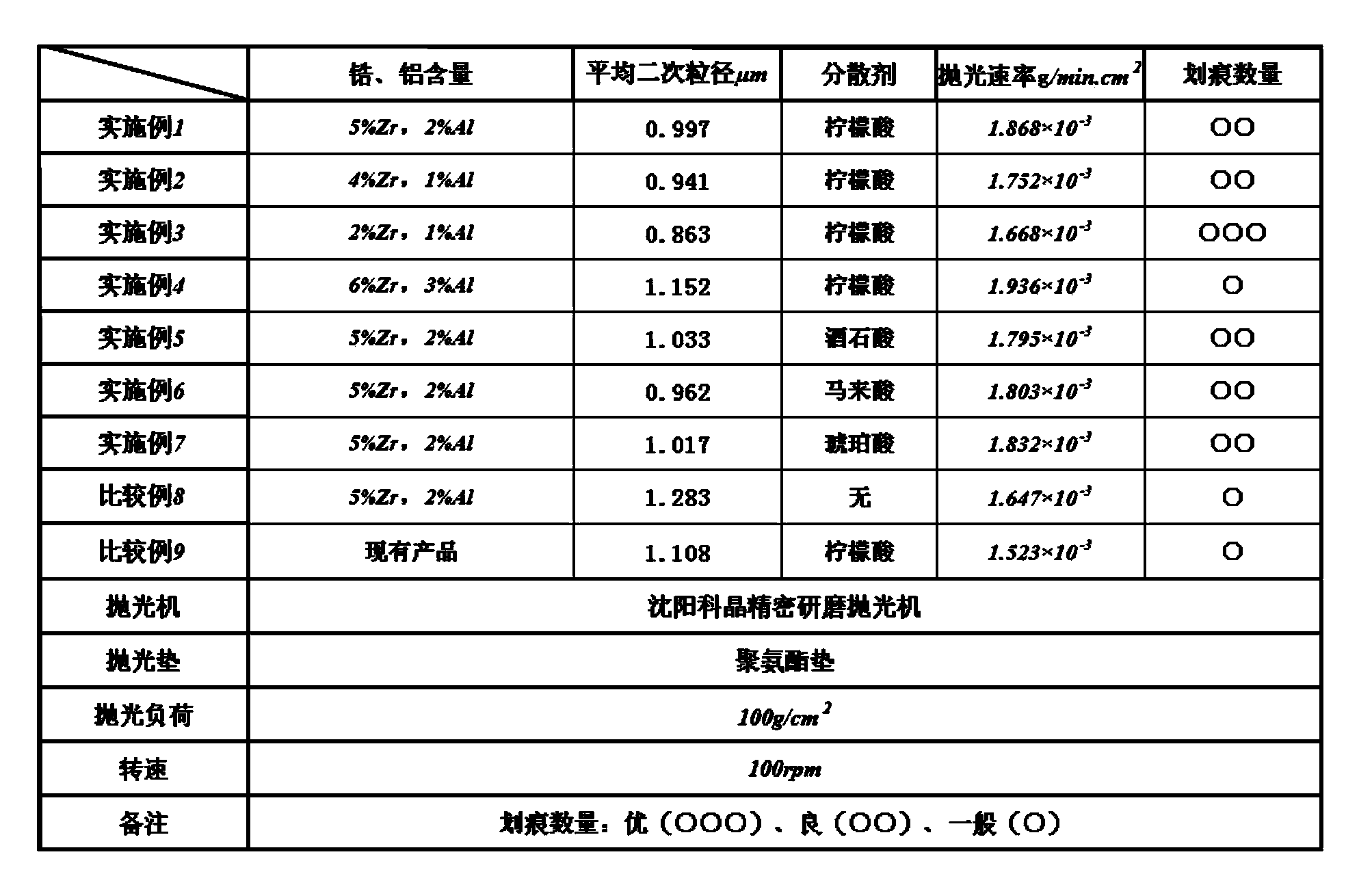

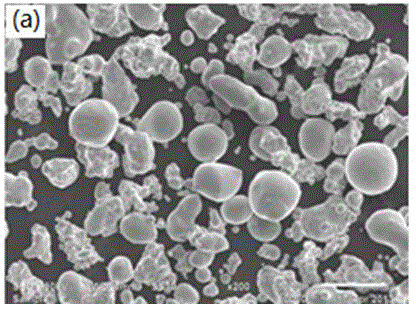

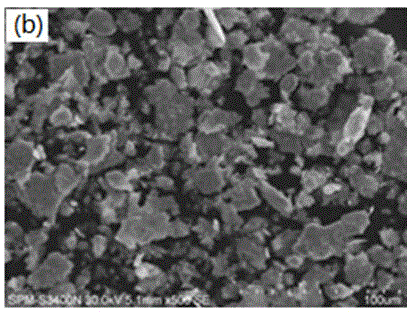

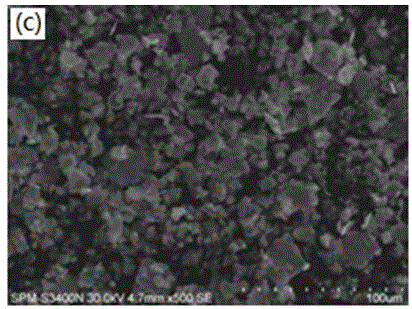

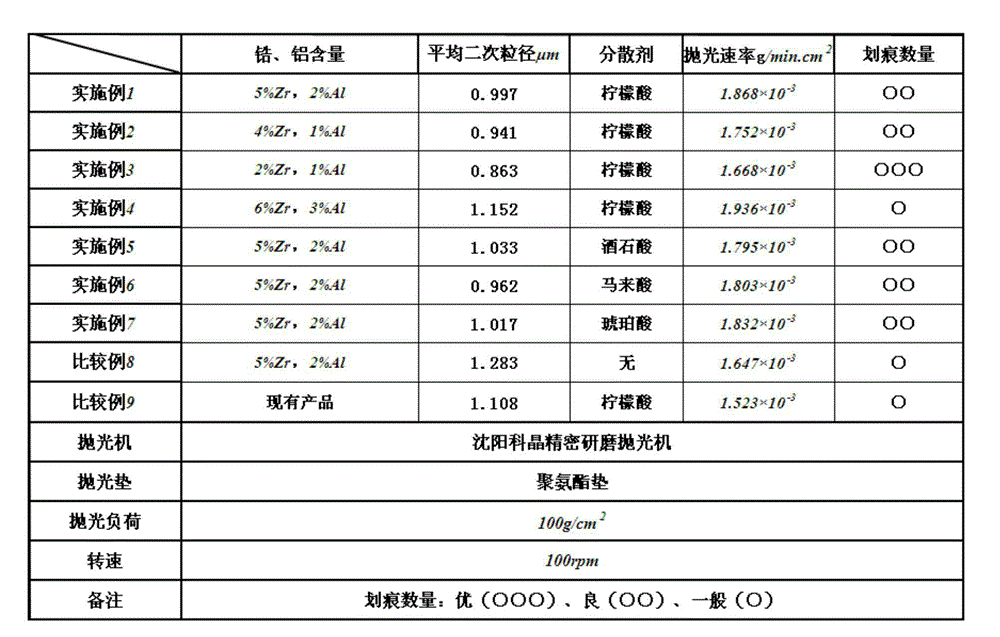

Preparation method of aluminium-doped cerium-zirconium solid-solution polishing powder

ActiveCN103450811AFine and uniform particle sizeGood suspensionPolishing compositions with abrasivesCeriumCoprecipitation

The invention discloses a preparation method of aluminium-doped cerium-zirconium solid-solution polishing powder and relates to the technical field of preparation of the polishing powder materials. The preparation method disclosed by the invention comprises the following steps of (1) preparation of colloidal solution; (2) preparation of a mixed system; (3) coprecipitation; and (4) roasting and aftertreatment. The preparation method disclosed by the invention has the characteristics of simple preparation process, cheap and easily available materials and suitability for industrial production and the like, is applicable to the field of processing of high-grade optical instruments and can be especially used for precise optical-glass polishing.

Owner:HUNAN HAOZHI TECH

Preparation method of pyrochlore type rare-earth titanate powder

ActiveCN108439462AHigh purityUniform chemical compositionMaterial nanotechnologyTitanatesRare earthPyrochlore

The invention discloses a preparation method of pyrochlore type rare-earth titanate powder. The preparation method adopts a soft chemical sol-gel method to prepare and comprises the following specificsteps: (1) weighing rare-earth nitrate powder and alcoholate of titanium respectively according to a stoichiometric ratio; (2) dissolving the rare-earth nitrate raw material into absolute ethyl alcohol at room temperature to obtain a solution A; adding acetylacetone and the alcoholate of titanium into the absolute ethyl alcohol at the same time to obtain a solution B; mixing the solution A and the solution B to obtain transparent sol; dropwise adding a diluted nitric acid solution into the transparent sol under the condition that the temperature is 40 to 60 DEG C and continuously stirring; monitoring the pH (Potential of Hydrogen) value; stopping dropwise adding until the pH value is 4.0 to 5.0; standing for 15 to 30min to obtain transparent wet gel; (3) drying the wet gel for 12 to 24h under the condition that the temperature is 100 to 120 DEG C; grinding to obtain powder; (4) putting the powder into a muffle furnace; keeping heat for 2 to 4h under the condition that the temperatureis 750 to 850 DEG C, so as to obtain the pyrochlore type rare-earth titanate powder. The preparation method disclosed by the invention has the advantages of simple preparation technology and low energy consumption; the prepared powder has uniform chemical composition and high product purity.

Owner:XINYI DONGFANG SHUOHUA OPTICAL MATERIALS CO LTD

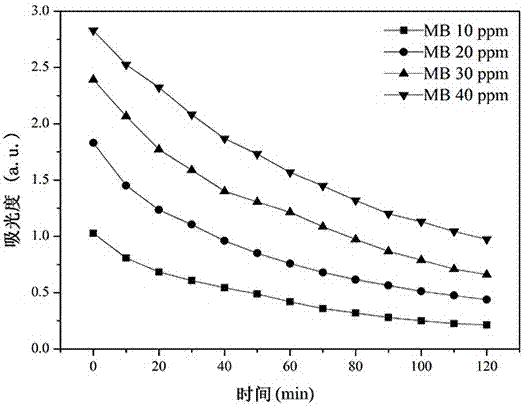

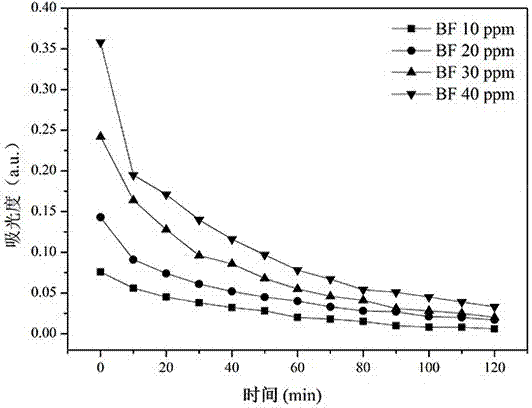

Efficient adsorbent based on ginkgo leaves and preparation method thereof

InactiveCN106902790AImprove performanceRealize the goal of treating waste with wasteOther chemical processesWater contaminantsSorbentOrganic dye

The invention discloses an efficient adsorbent based on ginkgo leaves and a preparation method thereof. The adsorbent is a product obtained by using the ginkgo leaves as a raw material, crushing, washing with water, washing with an alkali, washing with an acid, again washing with water and drying. The adsorbent has excellent adsorption effects on methylene blue (MB), basic fuchsin (BF), rhodamine B (RhB) and other a plurality of dyes, has a high adsorption rate, and can be used for the adsorption of organic dye pollutants in sewage. Compared with the prior art, the adsorbent uses the agricultural and forestry waste ginkgo leaves as the raw material, the product can be obtained by a simple and easy process, the object of treating waste with the waste can be realized, and the efficient adsorbent has the advantages of greenness, environmental-friendliness, low energy consumption, high efficiency, and the like, and is suitable for industrialized production.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing flake-shaped MWCNTs/Cu composite powder with small particle size

The invention relates to a method for preparing flake-shaped MWCNTs / Cu composite powder with a small particle size and belongs to the technical field of new material and composite power preparation. First, after MWCNTs and absolute ethyl alcohol are uniformly mixed, ultrasonic dispersion and suction filtration are carried out; grinding balls, spherical atomization copper powder with the particle size ranging from 80 micrometers to 120 micrometer and the processed MWCNTs are sequentially added into a horizontal high-energy stirring ball grinding mill, the whole ball milling process is completed in alternating conversion of the rotating speed, and the flake-shaped MWCNTs / Cu composite powder prepared is dispersed under 200rpm finally. The pure flake-shaped MWCNTs / Cu composite powder with the small particle size is prepared rapidly through the method, the median diameter D50 of the flake-shaped MWCNTs / Cu composite powder with the small particle size ranges from 20 micrometers to 30 micrometers, the production efficiency is high, the cost is low, and the method is suitable for industrial production.

Owner:KUNMING UNIV OF SCI & TECH

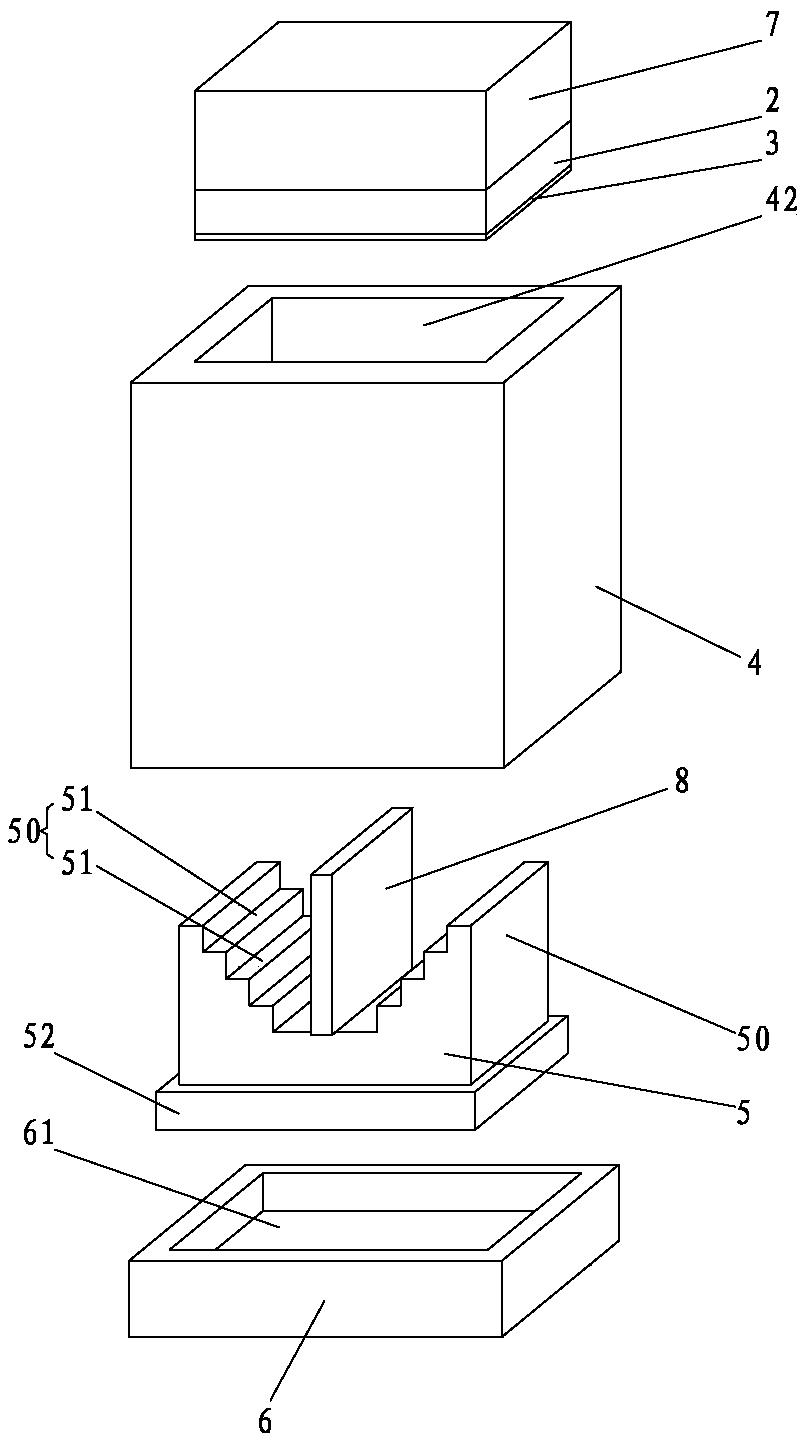

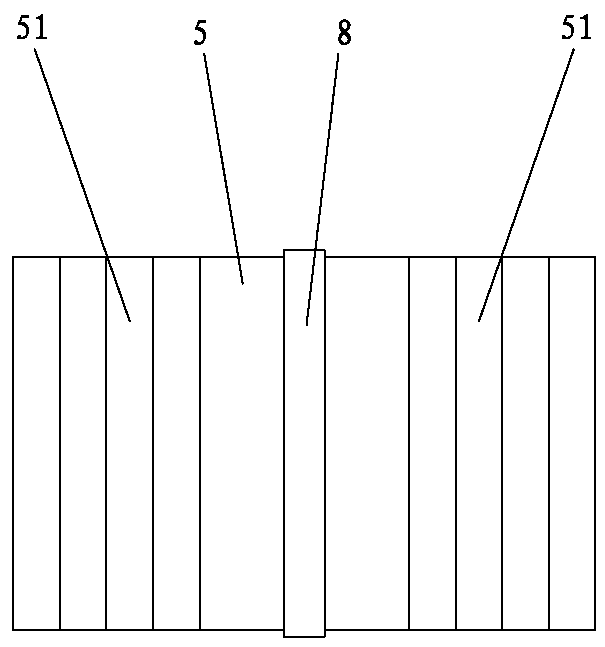

Novel brake pad and mold and method for preparing brake pad

ActiveCN104632958BReduce brake noiseNo poor braking effectFriction liningEngineeringToxic industrial waste

A novel brake pad and a mold and method for preparing the brake pad. The invention proposes a new type of brake pad, which includes a friction material block, and the friction working surface of the friction material block is formed with a plurality of stepped working surfaces with different heights and gradually raised or lowered. In this way, the step-by-step working surface of the present invention forms a step-shaped chamfer, which can effectively reduce brake noise and efficiently remove wear debris, and as the The consumption of the friction material block increases the friction area with the tire brake disc step by step, so that the braking effect will not be poor due to the smooth friction surface after long-term use. Therefore, the braking noise of the present invention is low, the chip removal effect is good, the friction effect is good, stable and durable, and has strong practicability. The invention also provides a mold, which can integrally form the brake pad, has no bad demoulding, high efficiency, strong bonding force, stable quality, low cost, material saving and no industrial waste. The invention also proposes a method with clear and concise steps, which can efficiently prepare integrally formed brake pads.

Owner:厦门市双晋材料科技有限公司

A treatment method for efficiently improving the microstructure and adsorption performance of attapulgite and diatomite

InactiveCN103084152BGood dispersionHigh porosityOther chemical processesWater/sewage treatment by sorptionPorositySorbent

The invention discloses a treatment method for effectively improving microstructures and absorption properties of attapulgite and kieselguhr. By using high-temperature pyrolysis, sputtering and Coulomb explosion effect generated by physical irradiation, a nanorod crystal structure inside the attapulgite is effectively decomposed and dispersed, and the specific surface area of the attapulgite is increased, and thus the absorption property of the attapulgite can be remarkably improved. Meanwhile, impurities in ducts of the kieselguhr can be removed, the porosity is increased, and thus the absorption property is improved. The modified clay can be used as a pesticide adhering assistant and an efficient absorbing agent for use.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

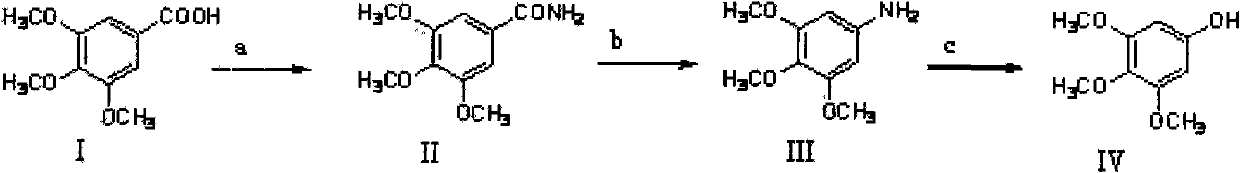

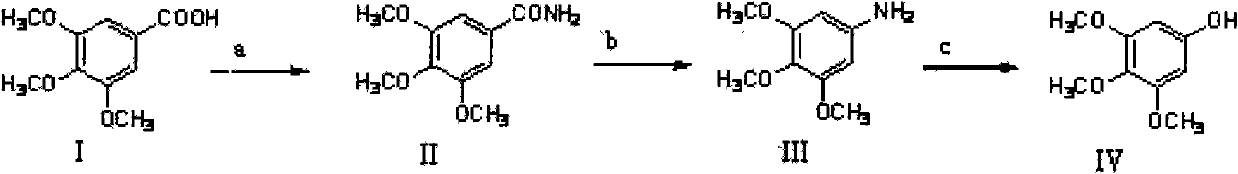

Method for preparing 3,4,5-trimethoxyphenol

InactiveCN101987814AEasy to useEasy to implementOrganic chemistryOrganic compound preparationOrganic synthesisHydrolysis

The invention discloses a method for preparing 3,4,5-trimethoxyphenol, relating to the field of organic synthesis. In the method, with 3,4,5-trimethoxybenzoic acid as a starting material, the 3,4,5-trimethoxyphenol is prepared by the processes of halogenation, ammonolysis, Hoffman rearrangement, diazotization and hydrolysis reaction, and the yield reach up to at least 60 percent. The method for preparing 3,4,5-trimethoxyphenol has rich raw material source, simple process, low cost and has wide industrial application prospect.

Owner:KPC PHARM INC +1

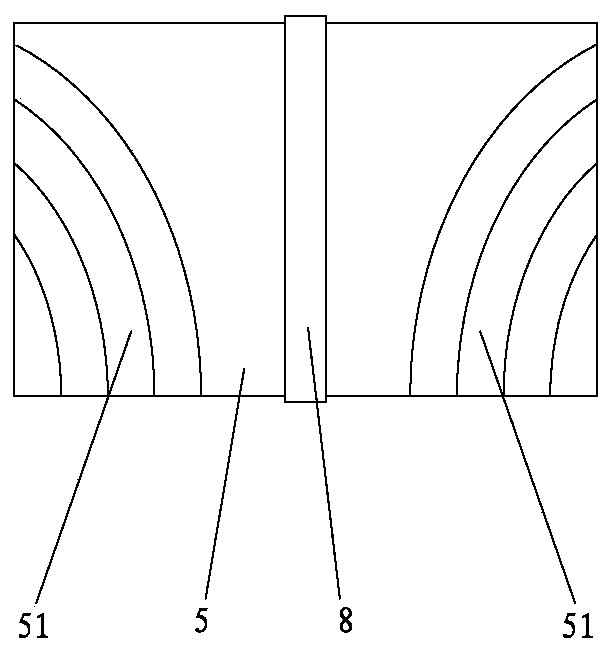

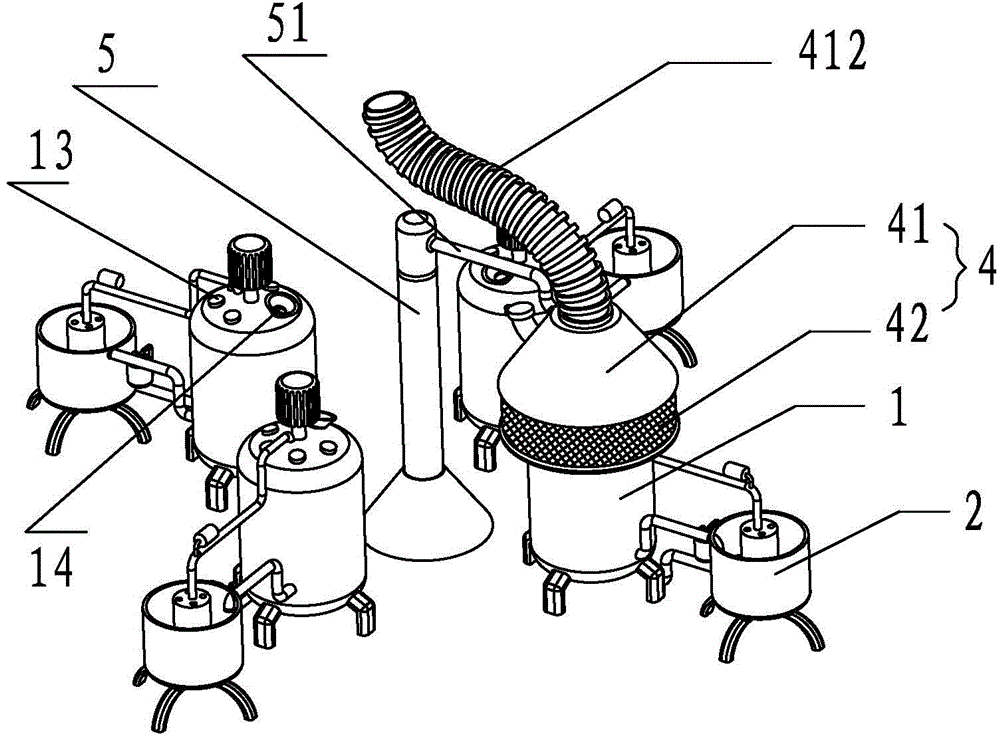

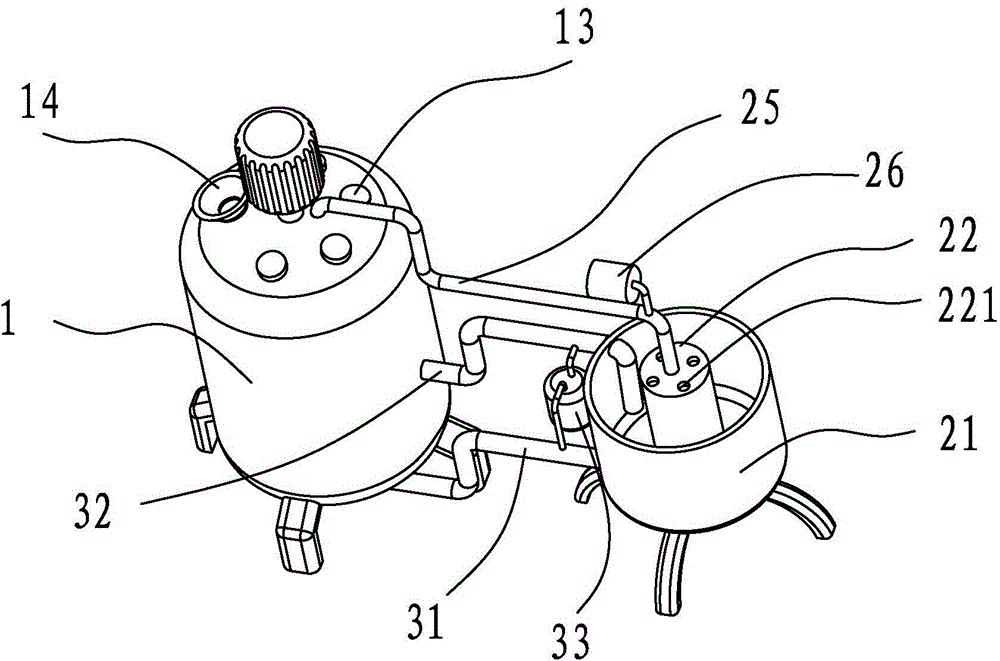

Cooling water circulation system of reaction kettle

InactiveCN104383861AImprove secondary usageIncrease water temperatureChemical/physical/physico-chemical stationary reactorsCooling chamberProcess engineering

The invention discloses a cooling water circulation system of a reaction kettle. The cooling water circulation system comprises a reaction kettle main body, wherein a reaction liner is arranged in the reaction kettle main body, a cooling chamber is arranged between the reaction liner and the reaction kettle main body, an independent reaction water heating device is arranged at the outer part of the reaction kettle main body, and comprises a main container, a single heating chamber is arranged inside the main container, a reaction water inlet pipeline is arranged above the heating chamber and communicated with the reaction liner, a cooling water drawing pipe and a cooling water inlet pipe are arranged between the main container and the cooling chamber, a one-way valve used for enabling cooling water to flow into the heating chamber is arranged between the main container and the heating cavity, and the cooling water after cooling can be recycled, so that the secondary utilization rate of resources is increased, and the energy consumption is reduced.

Owner:长兴三伟热熔胶有限公司

Preparation method of aluminium-doped cerium-zirconium solid-solution polishing powder

ActiveCN103450811BFine and uniform particle sizeGood suspensionSemiconductor/solid-state device manufacturingCeriumCoprecipitation

The invention discloses a preparation method of aluminium-doped cerium-zirconium solid-solution polishing powder and relates to the technical field of preparation of the polishing powder materials. The preparation method disclosed by the invention comprises the following steps of (1) preparation of colloidal solution; (2) preparation of a mixed system; (3) coprecipitation; and (4) roasting and aftertreatment. The preparation method disclosed by the invention has the characteristics of simple preparation process, cheap and easily available materials and suitability for industrial production and the like, is applicable to the field of processing of high-grade optical instruments and can be especially used for precise optical-glass polishing.

Owner:HUNAN HAOZHI TECH

Reflective thermal-insulating sand and preparation method thereof

The invention discloses reflective thermal-insulating sand and a preparation method thereof and belongs to the technical field of coating preparation. The sand comprises the following components in parts by weight: 80-90 parts of quartz sand, 40-60 parts of an emulsion, 20-40 parts of reflective thermal-insulating titanium dioxide, 20-30 parts of a functional filler, 0.1-1 part of a dispersion wetting agent, 5-10 parts of a film formation aid, 2-5 parts of other aids, 1-1.5 parts of a Ph value adjusting agent, 1-1.5 parts of a toner and 10-20 parts of deionized water. The sand has the characteristics of being excellent in reflective thermal-insulating effect, high in sunshine reflection rate and hemispherical emission rate, dense in coating film, smooth in surface, green and environment-friendly, free of VOC (volatile organic compound), free of industrial waste, good in heat preservation and dirt resistance, good in weather resistance, excellent in thermal insulation and long-lasting in thermal insulation; a color modulation process is simple, equipment requirements are low, the cost is low, and the raw material cost is low as water is adopted as a solvent.

Owner:郑州科威科建筑材料有限公司

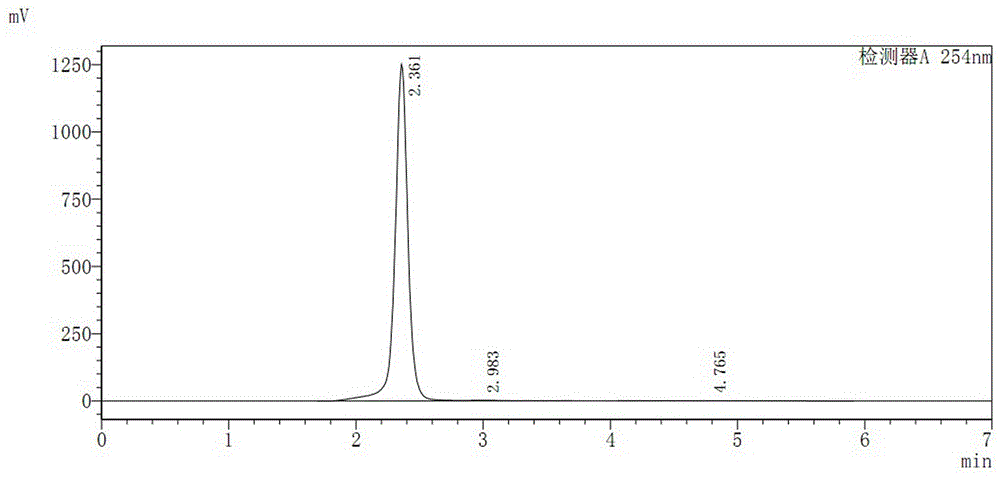

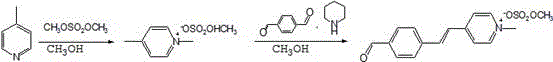

Synthesis method of novel SBQ photosensitive monomer

The invention discloses a synthesis method of a novel SBQ photosensitive monomer. The synthesis method comprises the following steps: by using an organic alkali catalyst instead of the traditional weak acid / strong acid acidic catalytic system, synthesizing an intermediate pyridine quaternary ammonium salt, adding the intermediate pyridine quaternary ammonium salt into an organic alkali mixed solution composed of methanol, toluene or any other organic solvent and terephthalaldehyde dropwisely or at one time, reacting under reflux for 5-8 hours, filtering to obtain a yellow homogeneous solution, cooling to crystallize, and purifying to obtain the brilliant yellow SBQ photosensitive monomer product with the purity of higher than 99%.

Owner:DENBISHI FINE CHEM KUSN

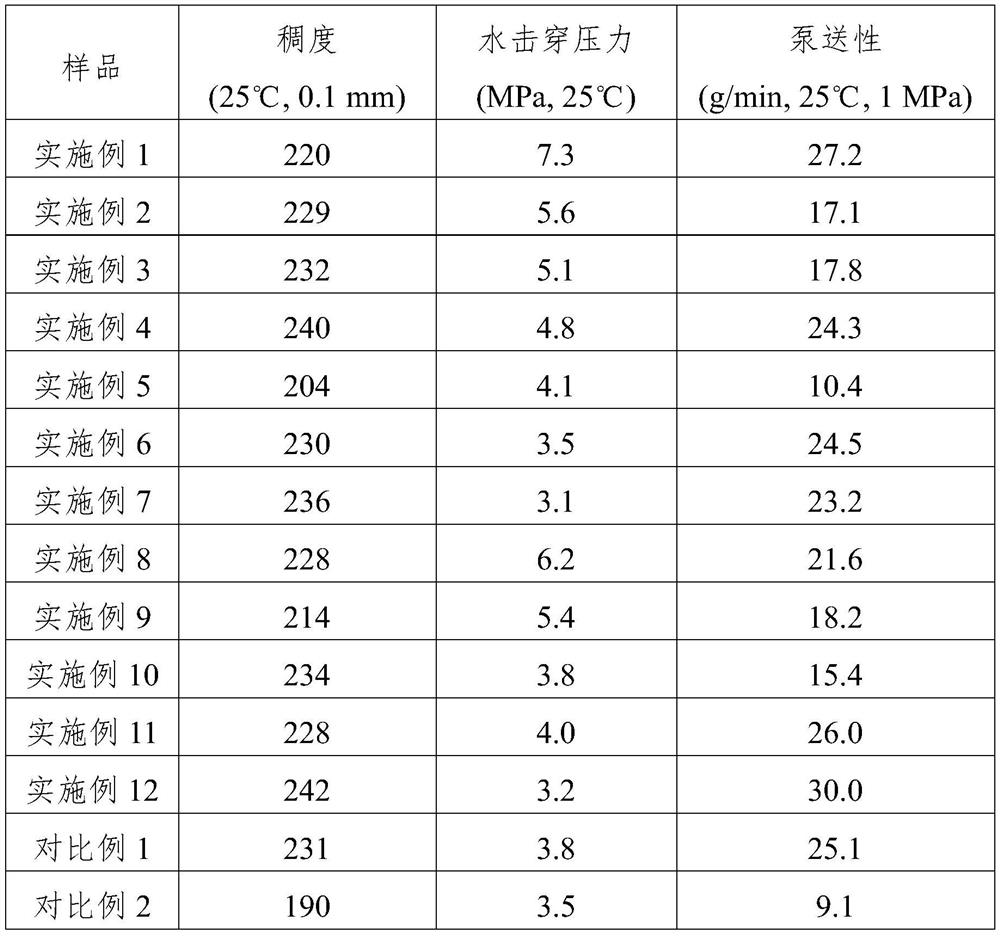

Eco-friendly shield tail sealing grease as well as preparation method and application thereof

ActiveCN114106912AEasy to prepareNo chemical reactionLubricant compositionOil and greaseEcological environment

The invention relates to eco-friendly shield tail sealing grease as well as a preparation method and application thereof, and the sealing grease comprises the following components in parts by weight: 15-40 parts of base oil, 5-20 parts of a tackifier, 1-5 parts of a thickening rheological agent, 1-5 parts of an adhesion improver, 3-8 parts of a reinforcing agent and 30-50 parts of a filler. The sealing grease provided by the invention is good in water pressure resistance and sealing performance, excellent in pumpability and strong in adhesion; meanwhile, most of the components are natural, non-toxic, renewable and biodegradable, pollution of shield tail sealing grease to underground water, the environment and structures can be avoided, and continuous improvement of the ecological environment is promoted.

Owner:北京中铁新材料技术有限公司 +1

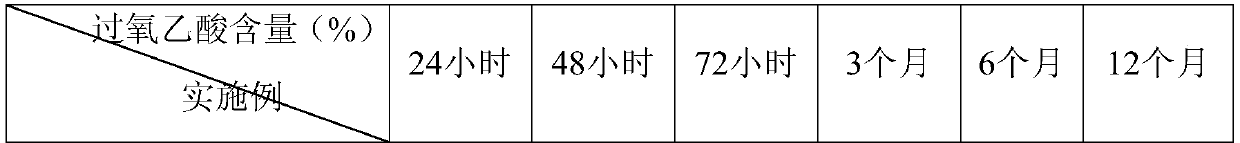

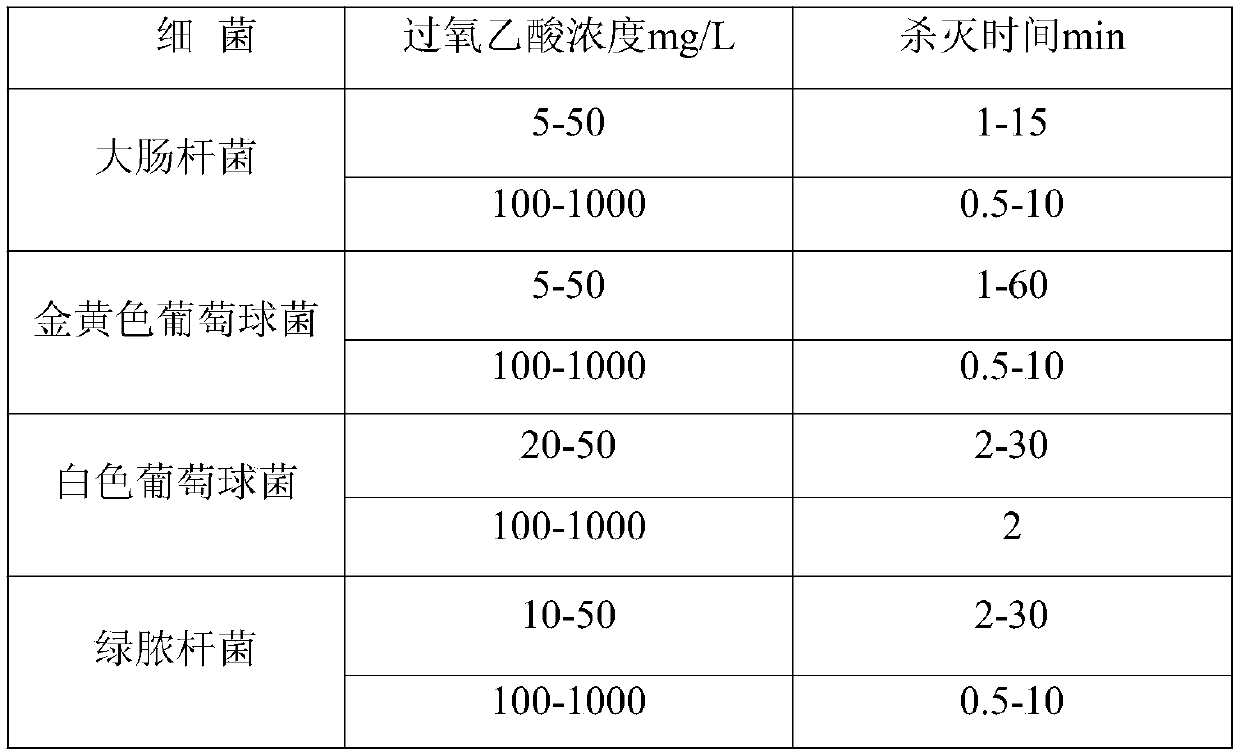

Environment-friendly peroxyacetic acid disinfectant and preparation method and application thereof

InactiveCN111436434AThe synthesis process is simple to operateNo pollution in the processBiocideFungicidesBiotechnologyAcetic acid

The invention discloses an environment-friendly peracetic acid disinfectant and a preparation method and application thereof, and belongs to the technical field of pharmaceutical chemicals. The invention provides a peracetic acid disinfectant. The peracetic acid disinfectant is prepared from glacial acetic acid, hydrogen peroxide, citric acid, boric acid, sodium citrate and urea. The volume ratioof glacial acetic acid to hydrogen peroxide is 1-2:1-3; the addition amount of the citric acid is 1-10% of the mass of the glacial acetic acid; the addition amount of the boric acid is 1-10% of the mass of the hydrogen peroxide; the addition amount of the sodium citrate is 0.1-0.3% of the total mass of the materials; and the addition amount of the urea is 0.1-0.2% of the total mass of the materials. The peracetic acid disinfectant disclosed by the invention is simple to synthesize and operate, free of environmental pollution and industrial three wastes, has the characteristics of high efficiency and broad spectrum, can quickly kill bacteria, viruses, fungi and spores, and is a green, environment-friendly, non-toxic, harmless and residue-free environment-friendly disinfectant.

Owner:成都百士洁生物科技有限公司

Method for preparing 1,3,4,6-hexamethyl-1,2,4-tetrahydronaphthalene by continuous reaction under catalysis of ionic liquid

InactiveCN102079686ASimple processHigh selectivityHydrocarbon from saturated and unsaturated hydrocarbon additionHydrogen halideP-isopropyltoluene

The invention discloses a method for preparing 1,3,4,6-hexamethyl-1,2,4-tetrahydronaphthalene by continuous reaction under catalysis of ionic liquid, which comprises the steps of: with acid room-temperature ionic liquid as a catalyst, cyclic hydrocarbon as a solvent, and cymene and olefin as raw materials, conducting alkylation reaction in the existence of a hydrogen transfer reagent, wherein the acid room-temperature ionic liquid catalyst is prepared by reaction of metal halide and alkyl-containing pyridine halogenated amine, alkyl-containing hydrogen halide of amine or alkyl-containing halogenated amine of imidazole. The method for preparing 1,3,4,6-hexamethyl-1,2,4-tetrahydronaphthalene has simple technical process, higher product selectivity and relatively considerable yield; the ionic liquid catalyst adopted in reaction can be separated from the reacting liquid easily and can be recycled; and the three industrial wastes are not generated in the technical process, thus the method for preparing 1,3,4,6-hexamethyl-1,2,4-tetrahydronaphthalene is a green and environment-friendly technique.

Owner:姜思田 +1

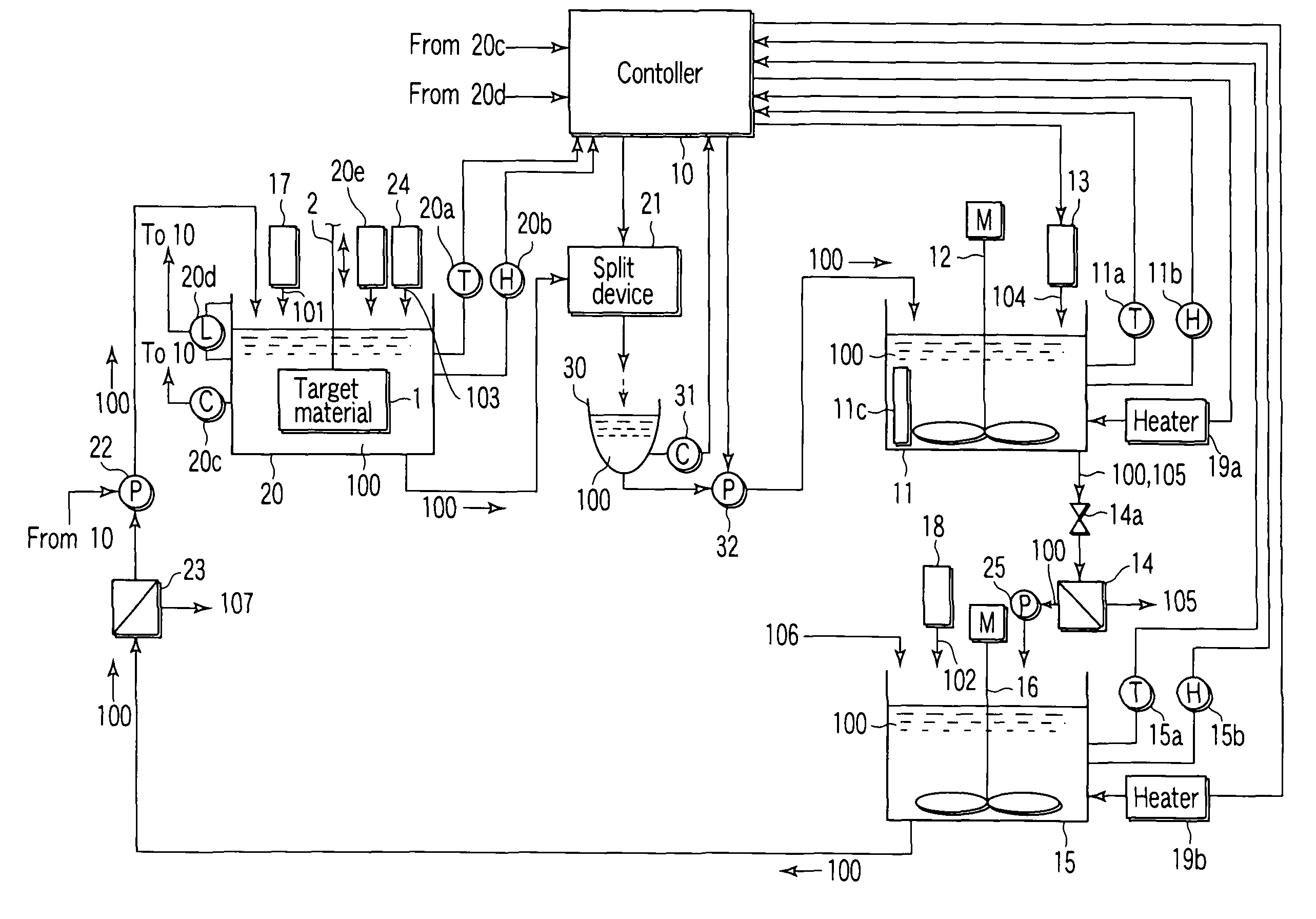

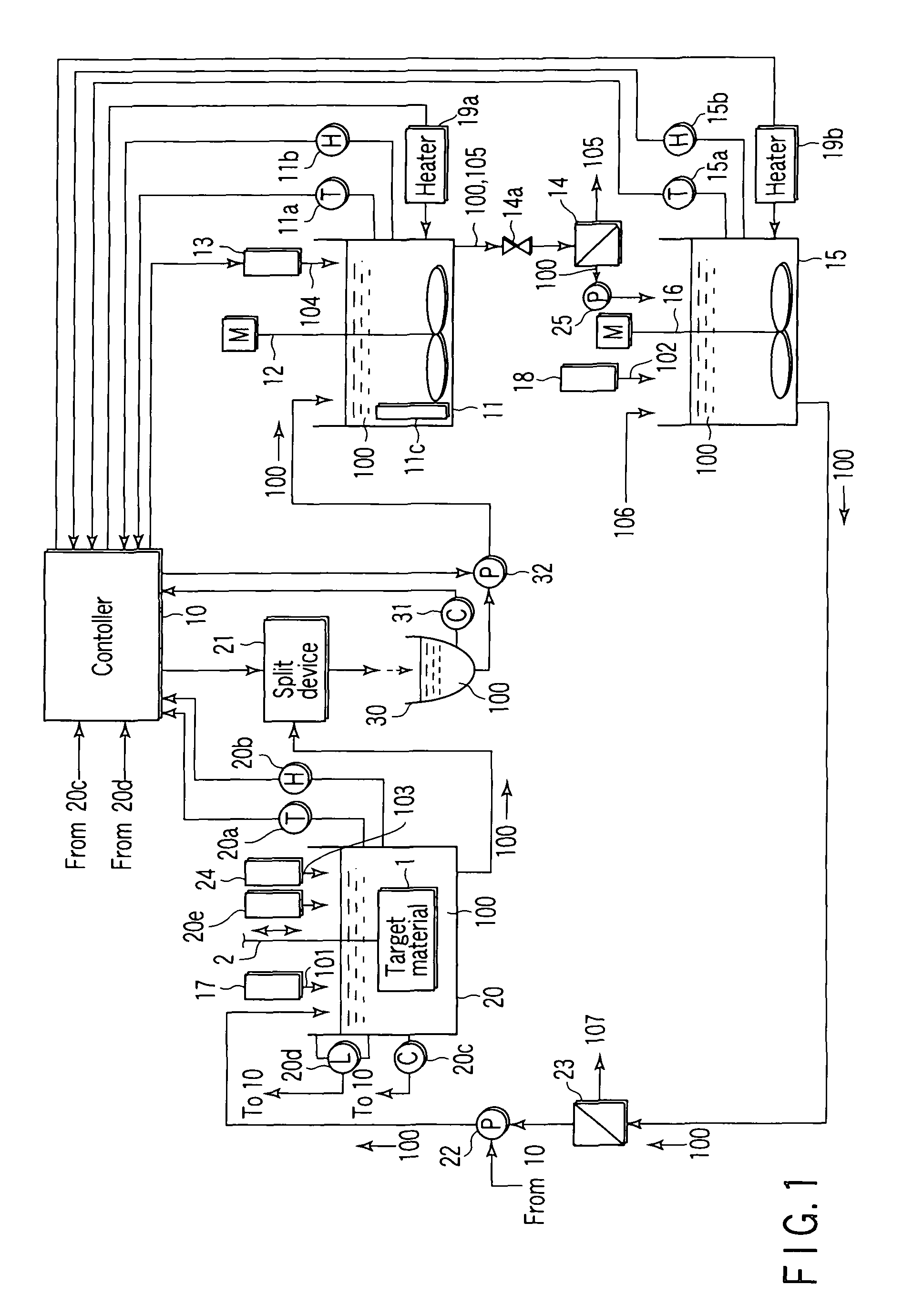

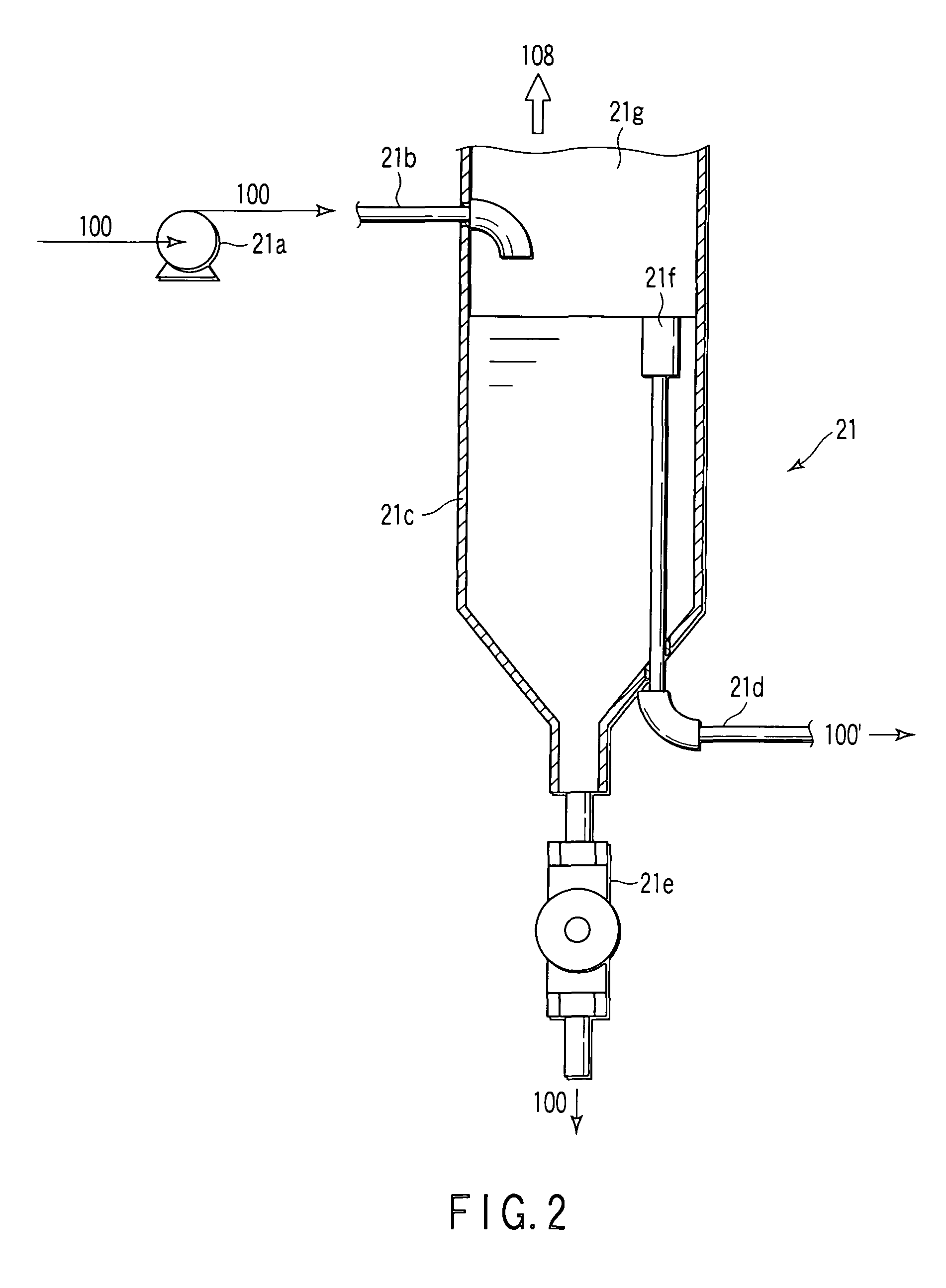

Regeneration apparatus and regeneration method for electroless plating

InactiveUS7892603B2Effective and practicalEfficiently and automatically regenerating treatmentLiquid separation by electricityIon-exchanger regenerationPhosphorous acidCalcium hydroxide

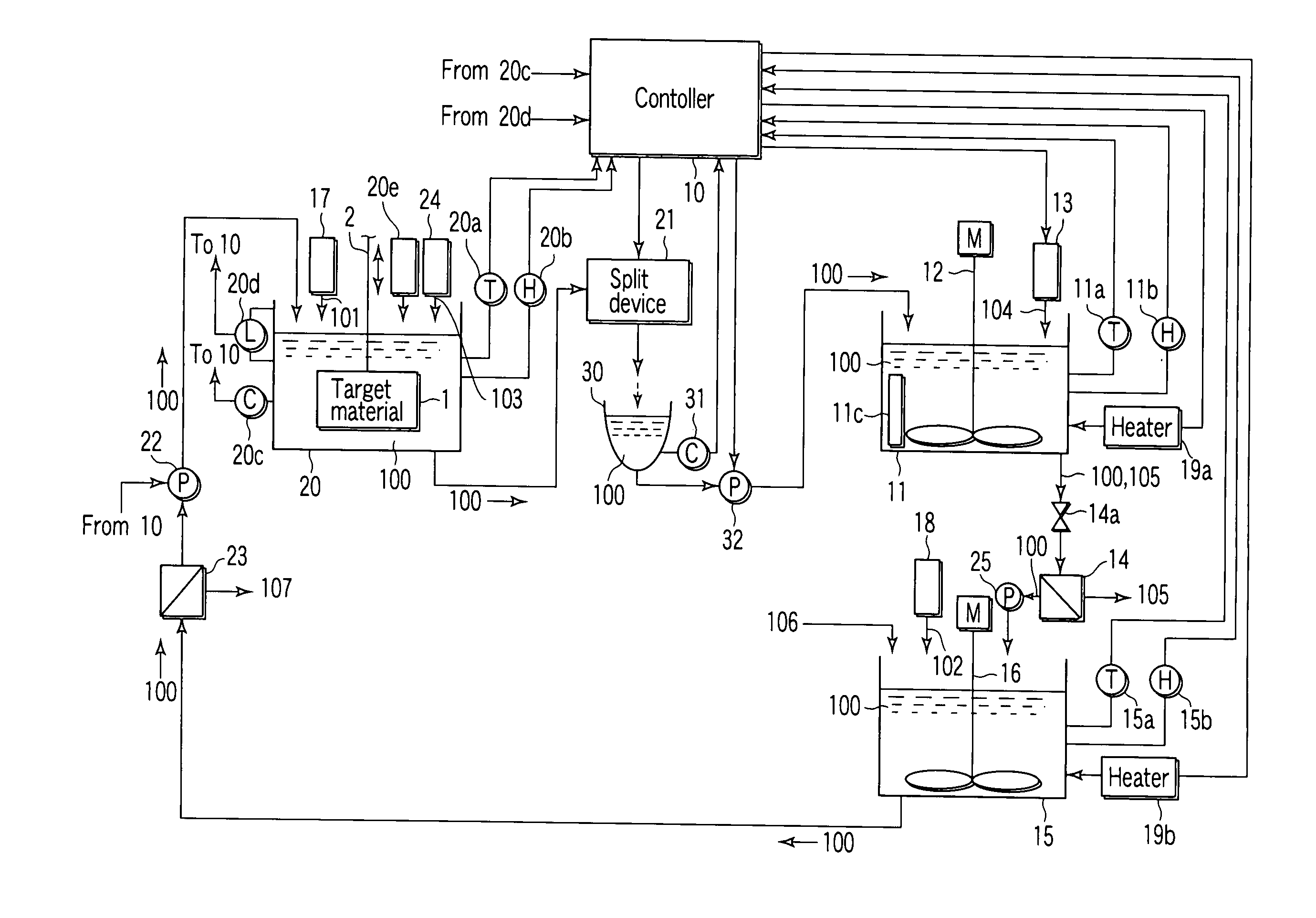

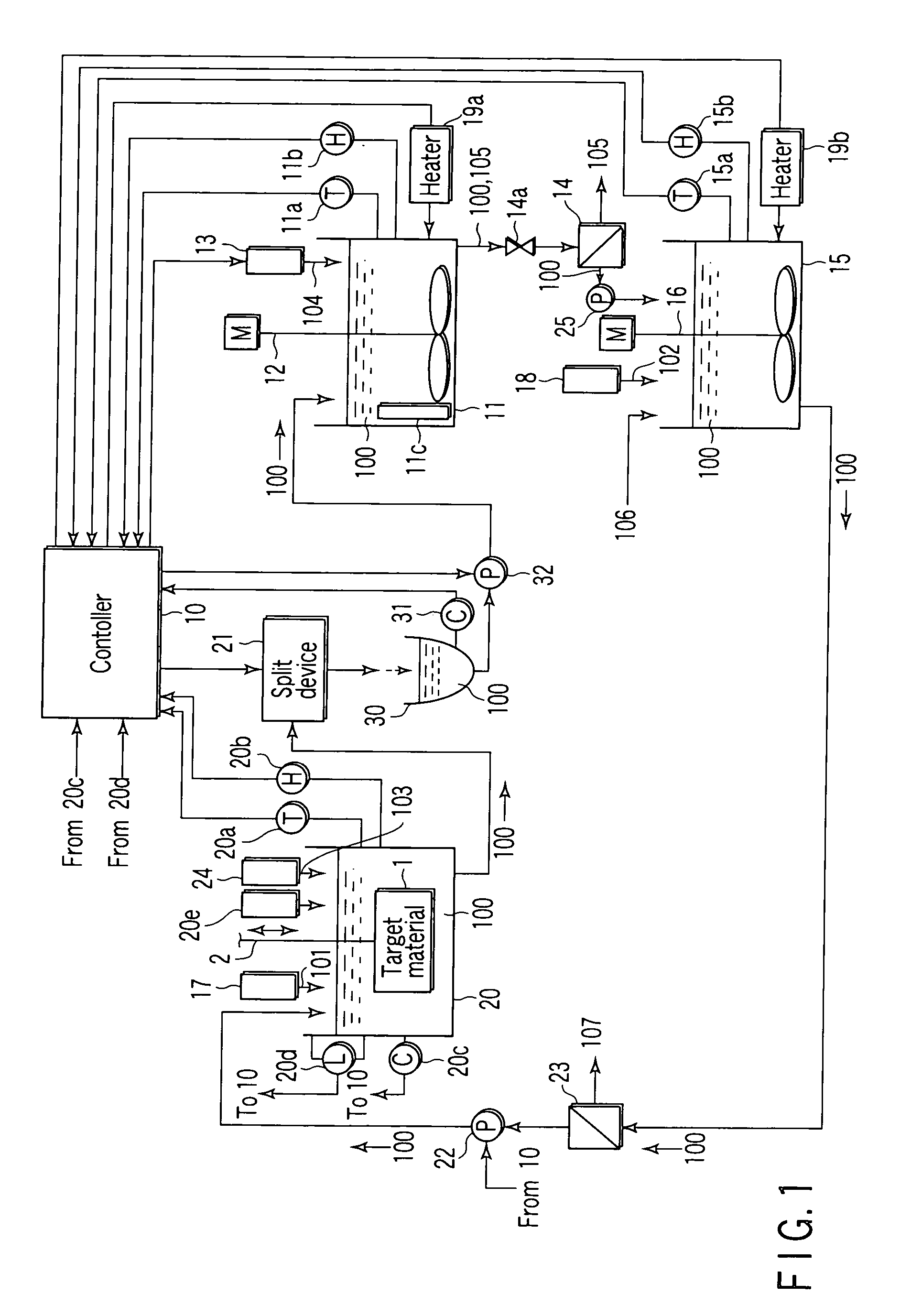

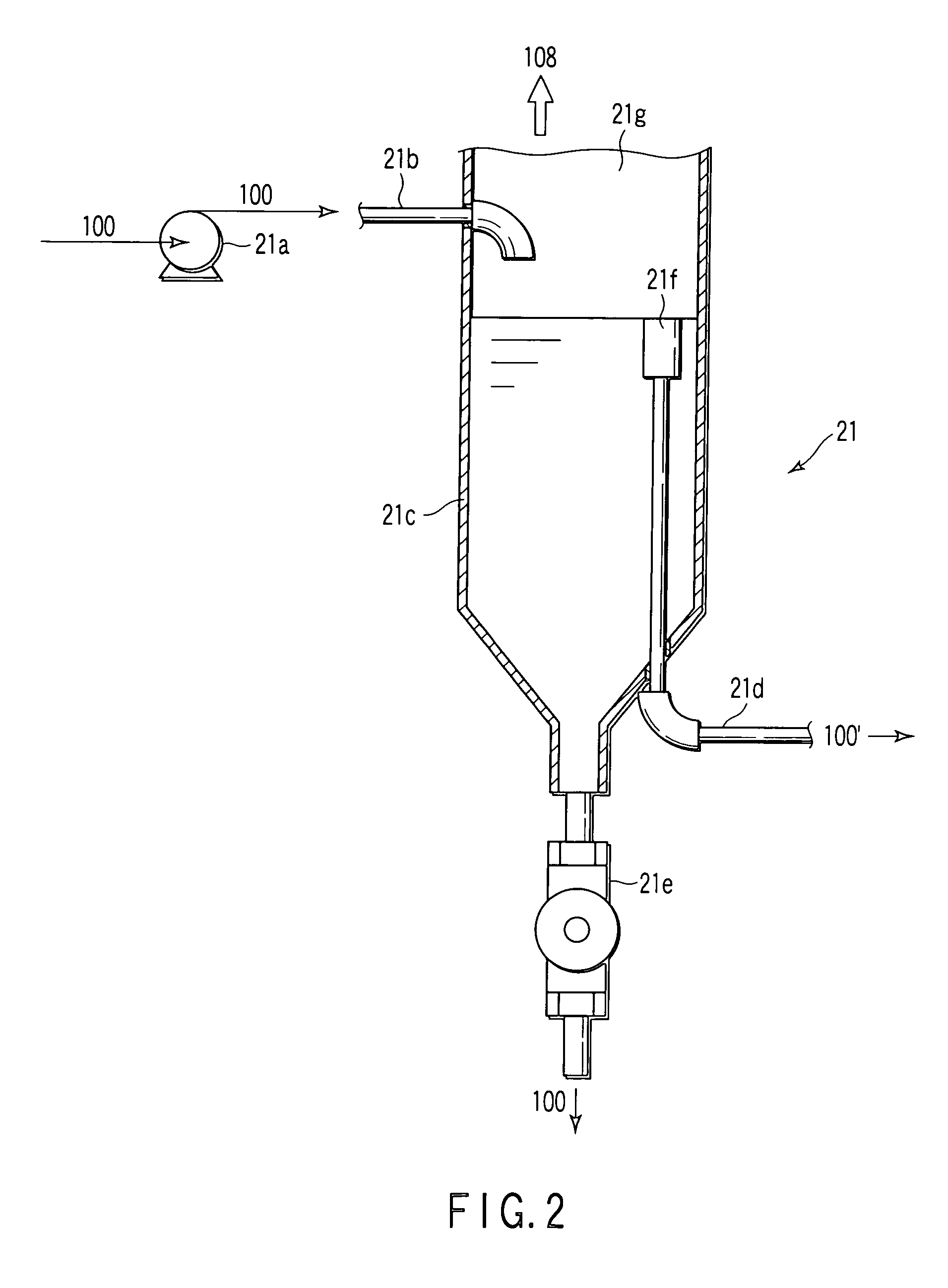

A regeneration apparatus for an electroless plating solution includes a sensor for measuring the formation rate of phosphorous acid formed in a plating tank in response to a plating treatment, a split device for taking out a plating solution in the plating tank to transfer the plating solution to a first processing tank, a sensor for measuring the concentration of the phosphorous acid contained in the plating solution taken out, an addition device for supplying calcium carbonate or calcium hydroxide, an amount of which is required for producing a calcium phosphite from the phosphorous acid contained in the plating solution, to the first processing tank, a separation device for separating and removing the calcium phosphite produced in the first processing tank from the plating solution, and a return pump for transferring the plating solution from which the calcium phosphite has been separated and removed to the plating tank.

Owner:MURATA KK

Regeneration apparatus and regeneration method for electroless plating

InactiveUS20070023284A1Effective and practicalEfficiently and automatically regenerating treatmentLiquid separation by electricityIon-exchanger regenerationCalcium hydroxidePhosphorous acid

A regeneration apparatus for an electroless plating solution includes a sensor for measuring the formation rate of phosphorous acid formed in a plating tank in response to a plating treatment, a split device for taking out a plating solution in the plating tank to transfer the plating solution to a first processing tank, a sensor for measuring the concentration of the phosphorous acid contained in the plating solution taken out, an addition device for supplying calcium carbonate or calcium hydroxide, an amount of which is required for producing a calcium phosphite from the phosphorous acid contained in the plating solution, to the first processing tank, a separation device for separating and removing the calcium phosphite produced in the first processing tank from the plating solution, and a return pump for transferring the plating solution from which the calcium phosphite has been separated and removed to the plating tank.

Owner:MURATA KK

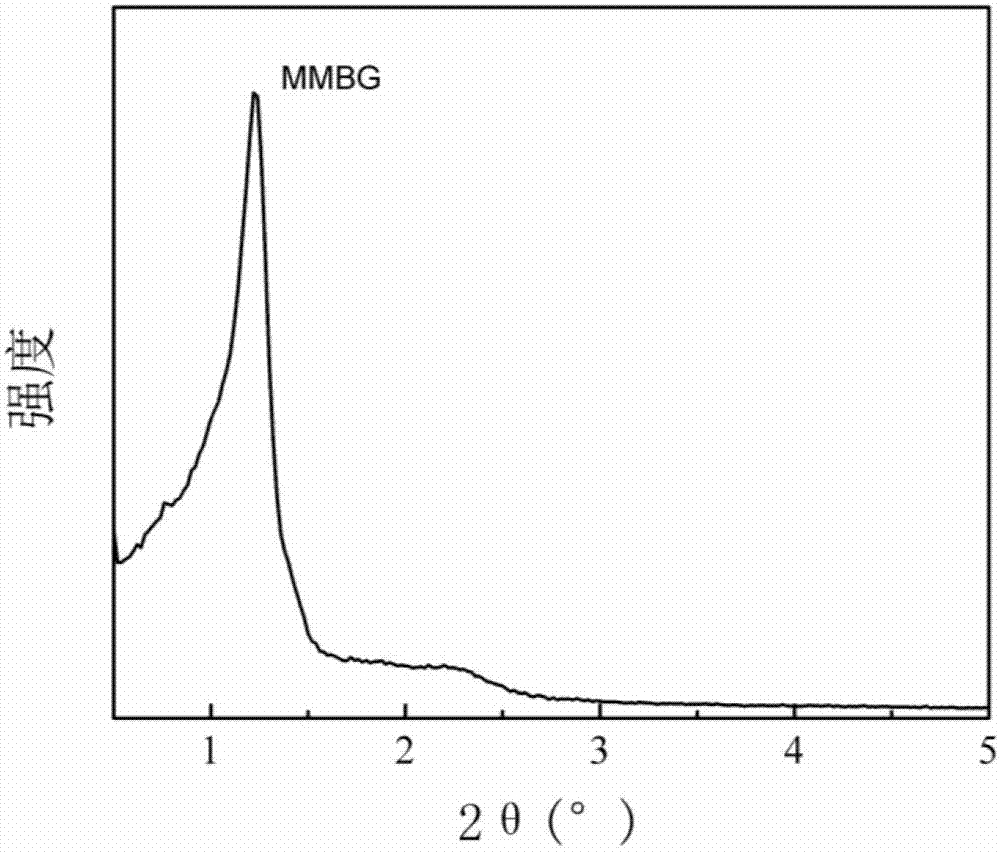

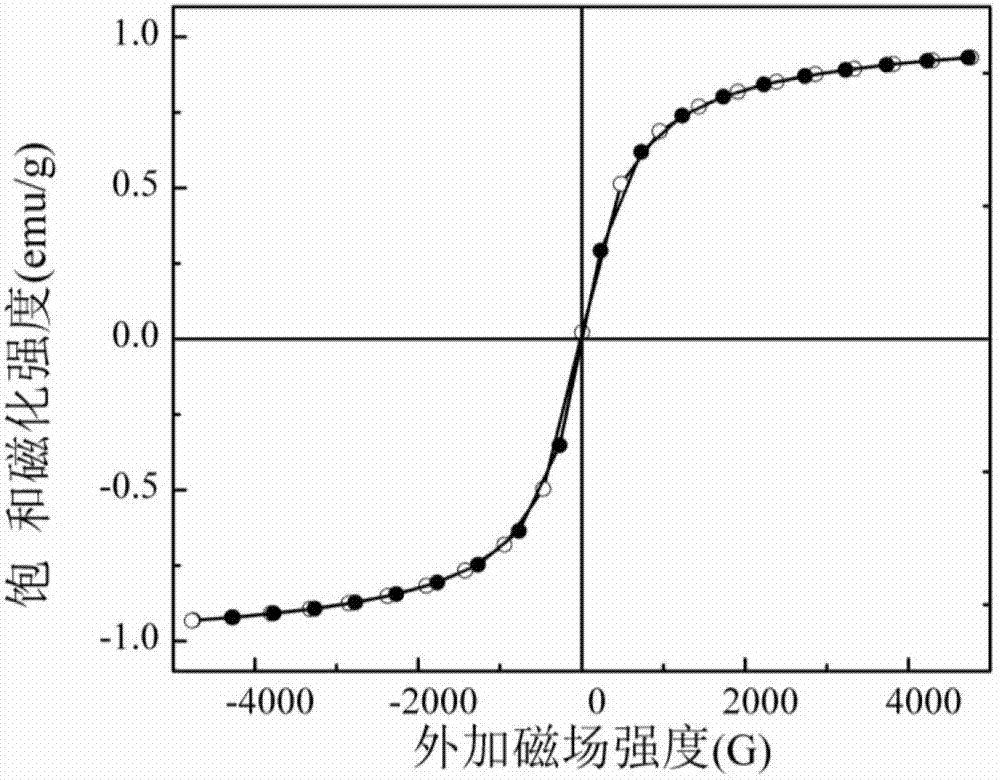

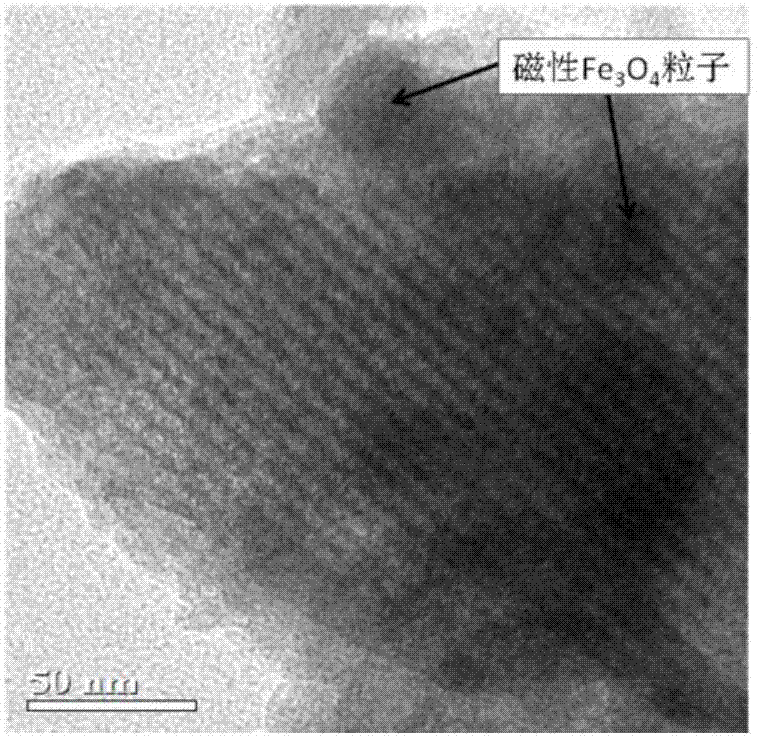

Magnetic mesoporous bioactive glass drug delivery system and preparation method thereof

InactiveCN102921010BRaw materials are easy to getThe synthesis method is simpleInorganic non-active ingredientsOrganic non-active ingredientsActive agentBioactive glass

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of high performance polycarboxylate water reducer

The invention relates to a preparation method of a high-performance polycarboxylic acid-based water-reducer, which uses ammonium persulfate as an initiator and copolymerizes monomers in an aqueous solution system, and the amount of ammonium persulfate accounts for the total amount of monomers. 0.5-10.0% by mass; wherein the monomers include allyl polyethylene glycol, polyethylene glycol monomethyl ether methacrylate, acrylic acid and acrylamide. The preparation of the polycarboxylate water-reducing agent of the present invention adopts the method of free radical polymerization, using water as the solvent, the process is simple and easy to control, and there is no industrial waste; and the product performance is excellent, with low dosage, high water-reducing rate, The slump loss is small, the adaptability to cement is strong, and the early and late strength of concrete are greatly improved.

Owner:RIZHAO PORT GRP LANSHAN PORT

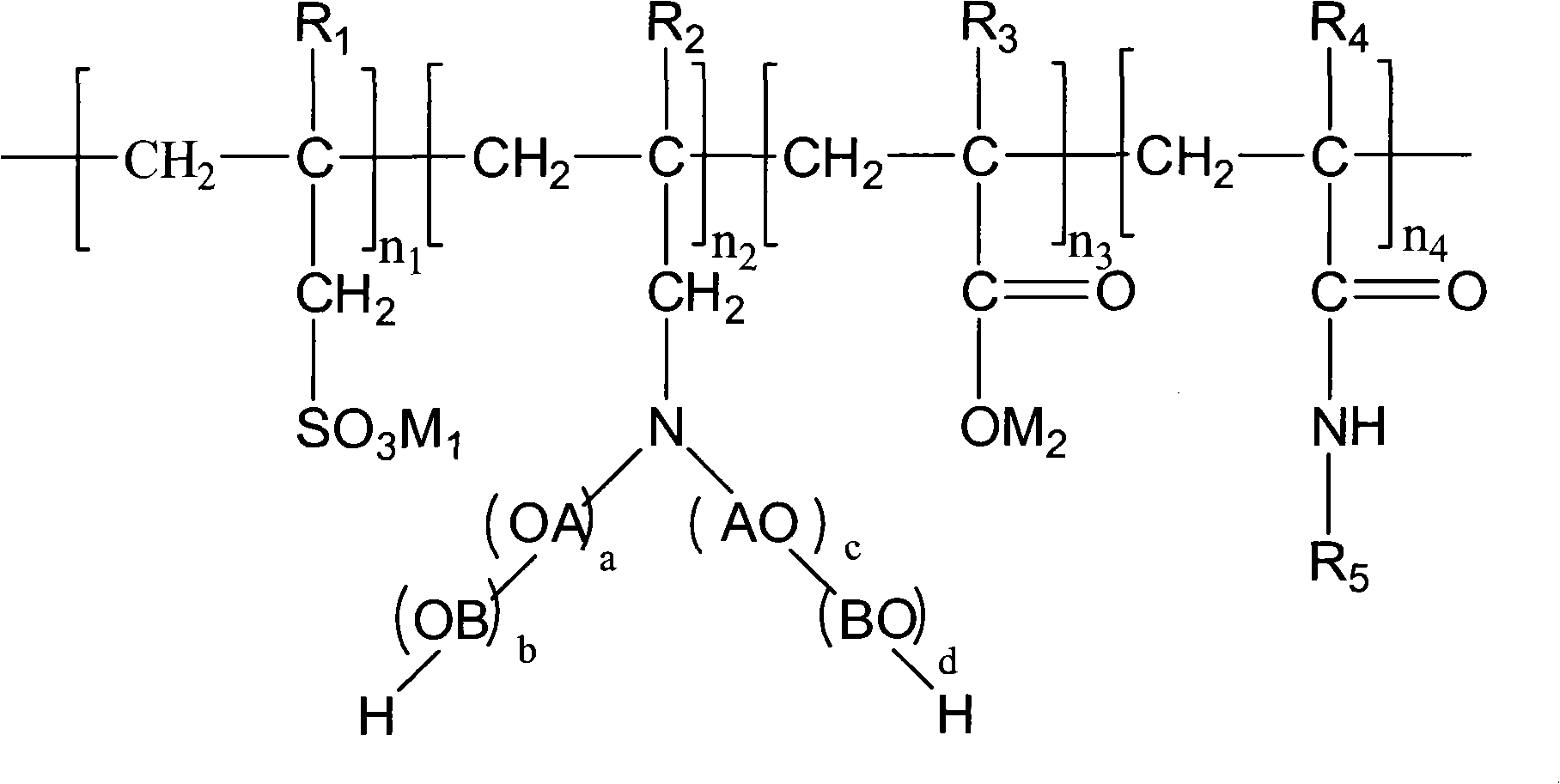

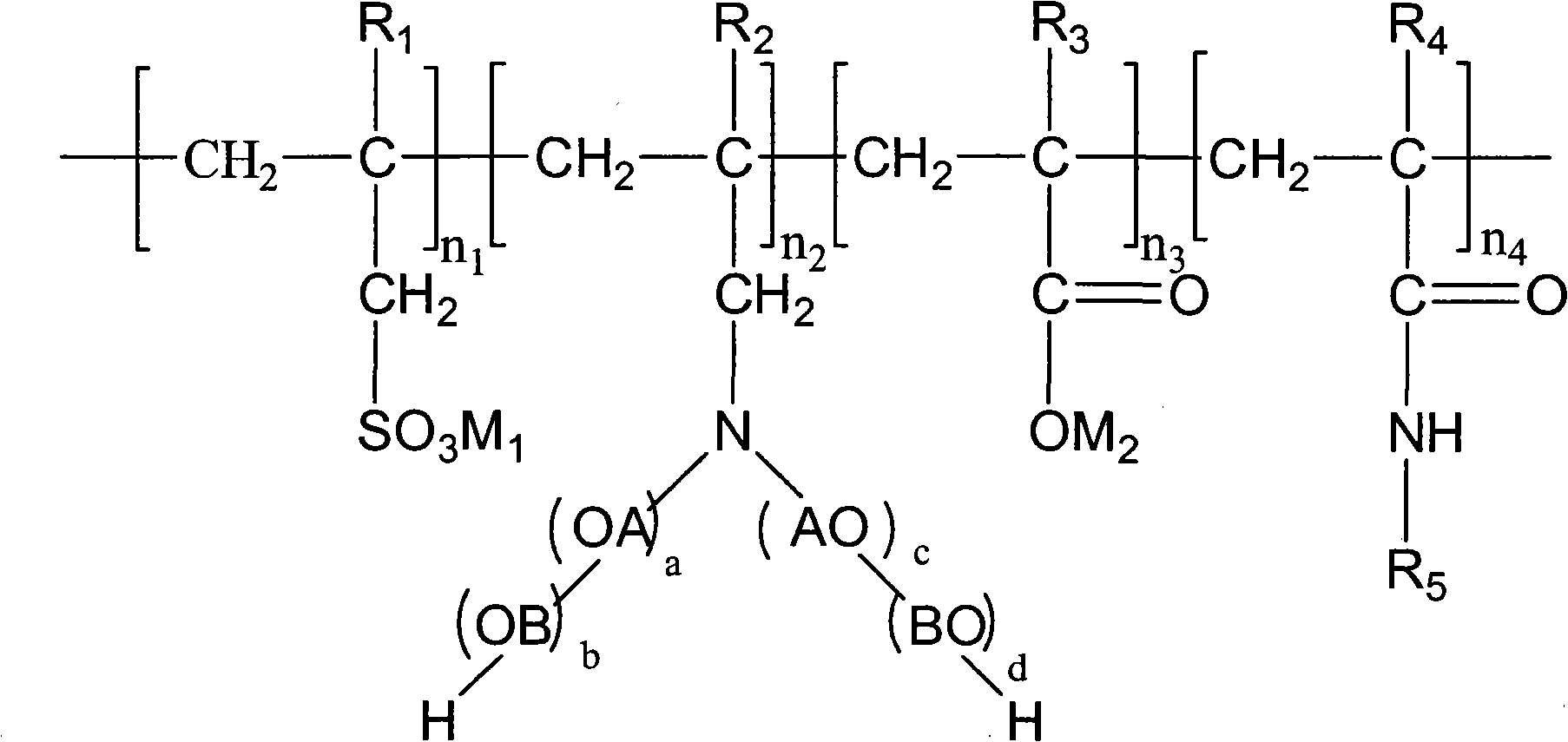

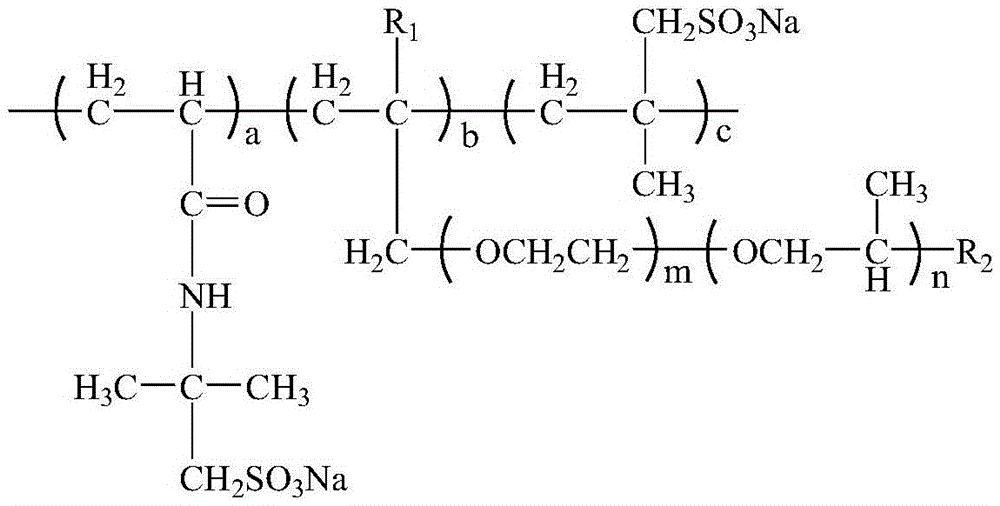

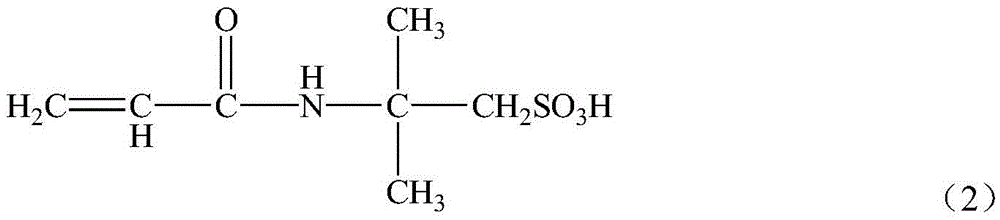

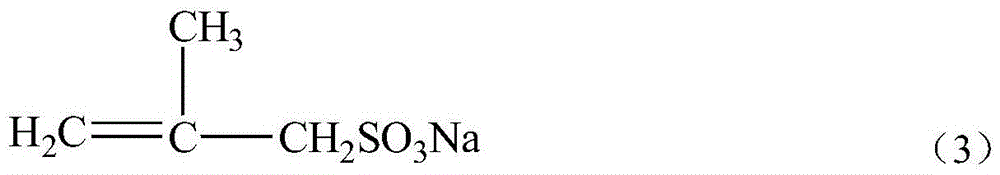

A kind of polymer sulfonate, its preparation method and its application in cement grinding aid

The invention relates to polymer sulfonate as well as a preparation method and application thereof in a cement grinding aid. The structural formula of polymer sulfonate is shown in the specification, wherein a ranges from 0 to 10, b ranges from 1 to 10, c ranges from 0 to 10, m ranges from 10 to 50 and n ranges from 0 to 20, and m is more than n; a and c are natural numbers or zero but are not zero at the same time; n is a natural number of zero; and both b and m are natural numbers; and the polymer sulfonate is copolymerized of an allyl polyoxyethylene polyoxypropylene monomer, a 1-acrylanmido-2-methylpropanesulfonic acid (AMPS) monomer and / or a sodium methyl allyl sulfonate (SMAS) monomer. The cement grinding aid disclosed by the invention is low in mixing amount, highly enhanced and highly dispersed, and can realize organic combination of multiple functional groups to take a synergistic effect together. The polymer sulfonate has the advantages of relatively simple production process, easily controlled reaction conditions, high purity and relatively low requirement on production equipment.

Owner:山东天汇科技有限公司

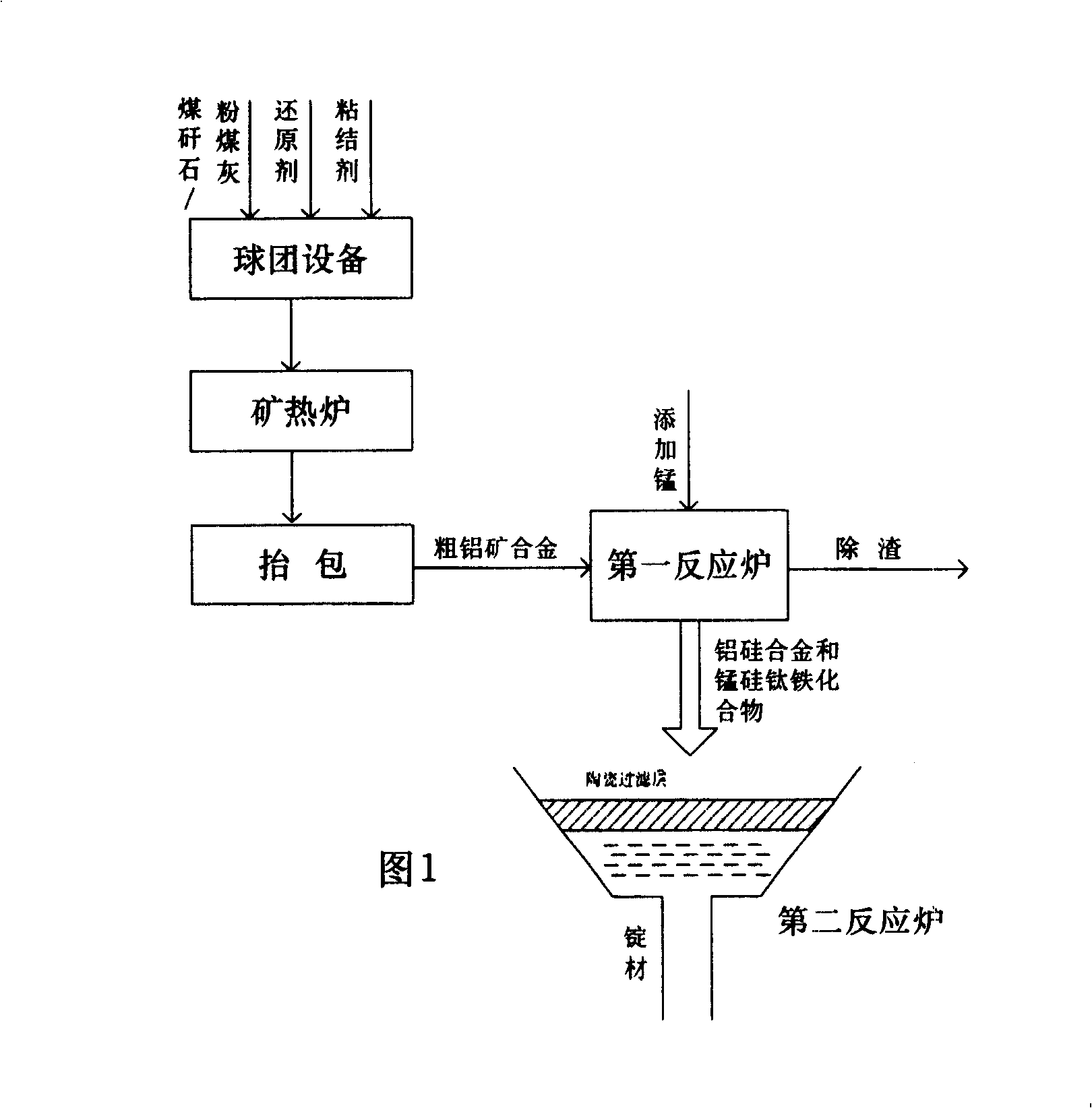

Process of refining aluminium silicon alloy from coal gangue or flyash

The process of refining Al-Si alloy with coal gangue or fly ash includes the following steps: 1. eliminating slag in conventional method, compounding with certain amount of manganese block in the first reaction furnace via electromagnetic stirring, lower the temperature gradiently to 590-610 deg.c to obtain Al-Si alloy and Mn-Si-Ti-Fe compound in laminated structure; and 2. filtering in the second reaction furnace with porous filtering ceramic layer in a funnel at the negative pressure of 800-1000 Pa, compounding with required alloy elements, and casting ingot with Al content over 85 %. The process operates based on the eutectic temperature property of Al-Si alloy to eliminate Si, Ti and Fe, and has short production process, low cost and no industrial waste.

Owner:山西泰尔钢铁有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com