Bacillus subtilis and use thereof in bio-control preparation for preventing and controlling powdery mildew

A technology of Bacillus subtilis and biocontrol preparations, applied in the application, biocide, fungicide and other directions, to achieve the effects of not producing industrial three wastes, good curing effect, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

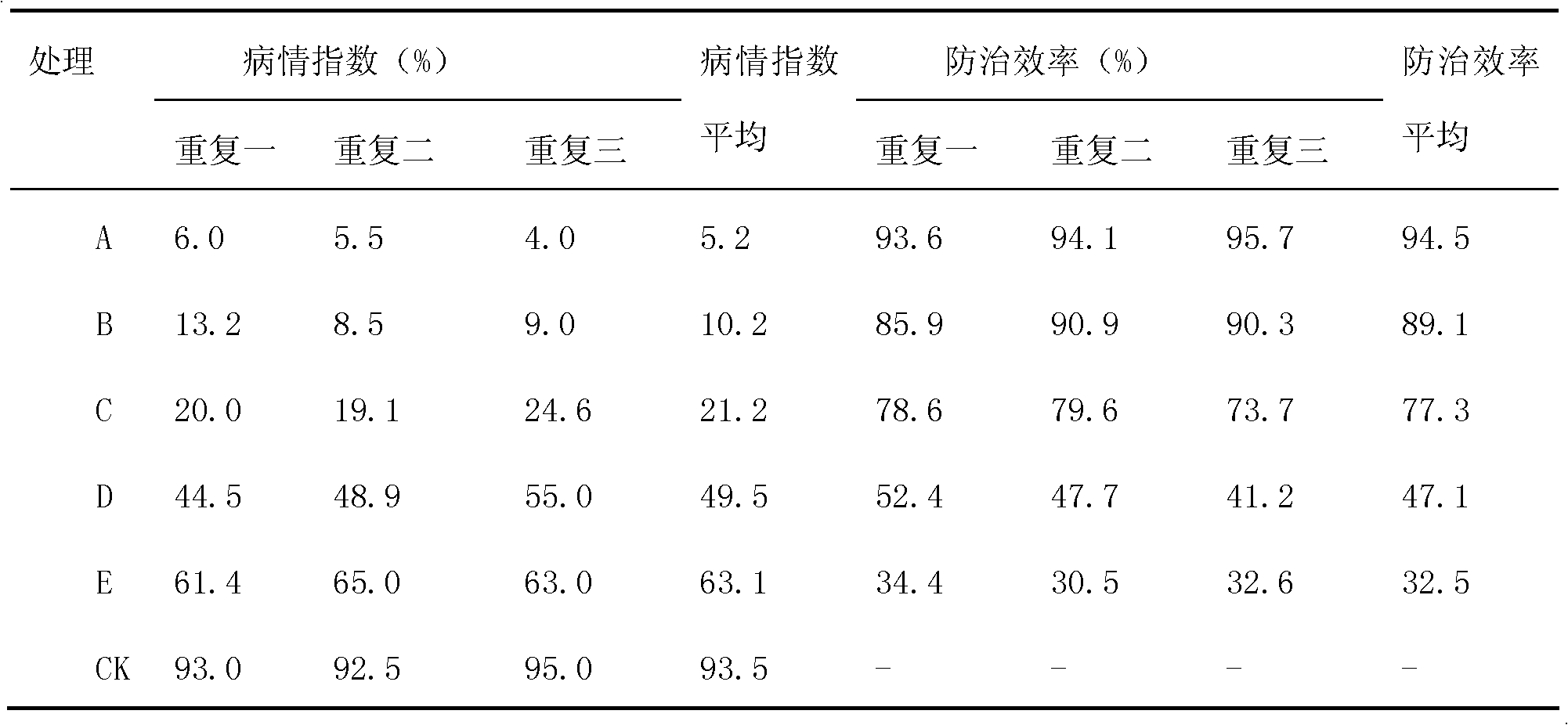

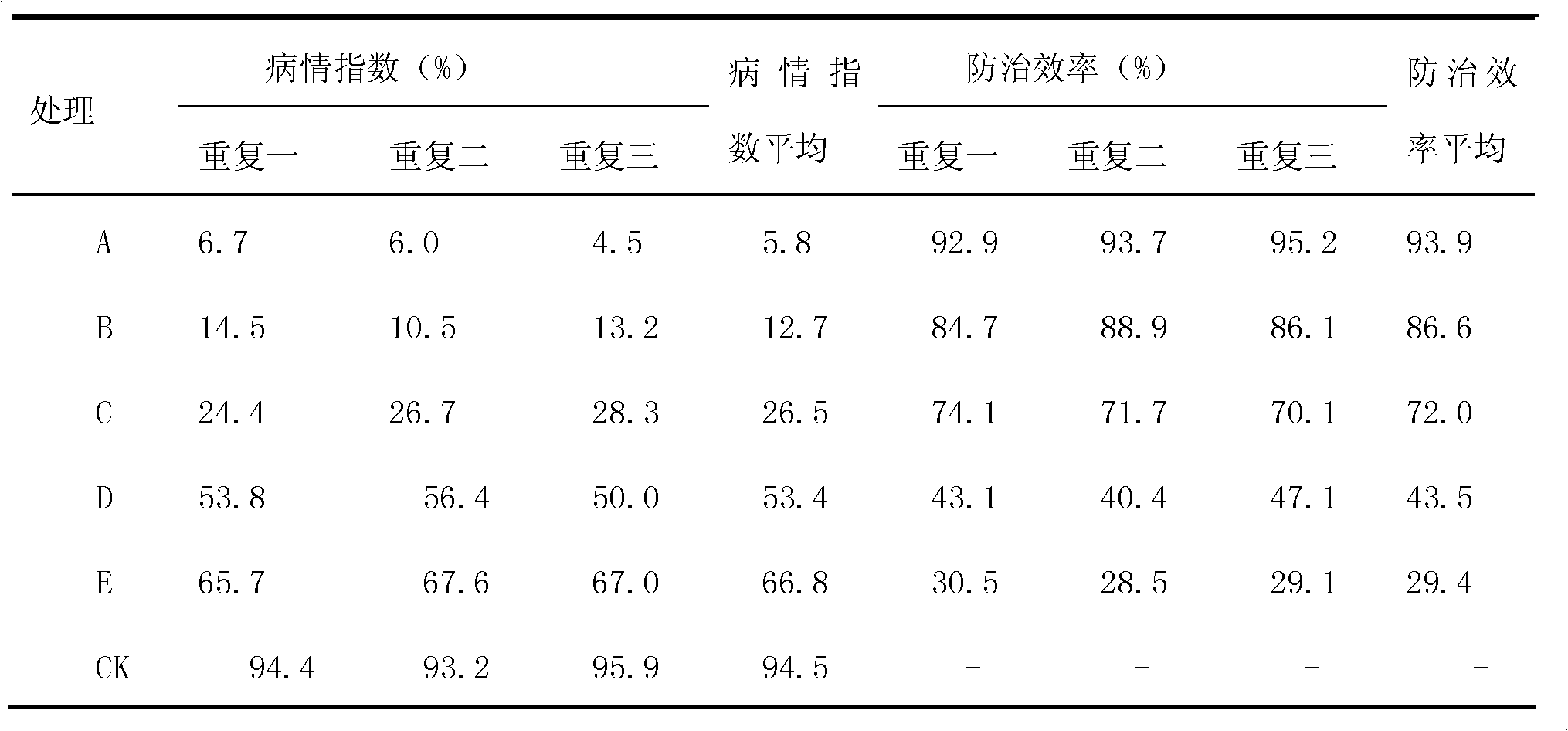

Examples

Embodiment 1

[0035] Strain activation and propagation:

[0036] The strain was activated by streaking on LB solid medium (1.0% tryptone, 0.5% yeast extract, 1.0% sodium chloride, pH 7.0, 1.5% agar), and streaking it in LB liquid medium (1.0% tryptone , 0.5% yeast extract, 1.0% sodium chloride, pH value is about 7.0) propagation to obtain fermented seeds.

[0037] Industrial fermentation:

[0038] Medium: corn flour 1%, soybean flour 1.5%, yeast powder 0.1%, peptone 0.5%, potassium dihydrogen phosphate 0.8%, calcium carbonate 0.15%, magnesium sulfate 0.02%, antifoaming agent 0.005%, sucrose 2.0%, pH 7.0; Fermentation conditions: Fermentation temperature is 28-35℃, aeration rate is 0.4v / v / min, stirring speed is 100 revolutions / min, 24 hours; during the fermentation process, sampling once every 2 hours to determine pH , Observe the colony morphology. When the number of spores reaches 5%, add the material once. When the number of spores reaches 90%, stop the fermentation, and observe whether it is...

Embodiment 2

[0040] Strain activation and propagation:

[0041] The strain was streaked and activated on LB solid medium (1.0% tryptone, 0.5% yeast extract, 1.0% sodium chloride, pH value around 7.0, 1.5% agar), and in LB liquid medium (1.0% tryptone , 0.5% yeast extract, 1.0% sodium chloride, pH value is about 7.0) propagation to obtain fermented seeds.

[0042] Inoculate fermented seeds to 0.8% corn flour, 1.5% soybean flour, 0.1% yeast powder, 0.5% peptone, 0.8% potassium dihydrogen phosphate, 0.15% calcium carbonate, 0.02% magnesium sulfate, 0.005% defoamer, pH 7.0; Fermentation conditions: fermentation temperature is 28℃, aeration rate is 0.2v / v / min, stirring speed is 100 revolutions / min, fermentation time is 36 hours; during the fermentation process, take samples once every 2 hours, measure pH value, and observe Colony morphology. When the number of spores reaches 5%, add the material once. When the number of spores reaches 90%, stop the fermentation, and observe whether it is a biologi...

Embodiment 3

[0044] Strain activation and propagation:

[0045] The strain was streaked and activated on LB solid medium (1.0% tryptone, 0.5% yeast extract, 1.0% sodium chloride, pH value around 7.0, 1.5% agar), and in LB liquid medium (1.0% tryptone , 0.5% yeast extract, 1.0% sodium chloride, pH value is about 7.0) propagation to obtain fermented seeds.

[0046] Inoculate fermented seeds to 0.8% corn flour, 1.5% soybean flour, 0.1% yeast powder, 0.5% peptone, 0.8% potassium dihydrogen phosphate, 0.15% calcium carbonate, 0.01% magnesium sulfate, 0.005% defoamer, pH 5.5; Fermentation conditions: fermentation temperature is 30℃, aeration rate is 0.2v / v / min, stirring speed is 100 rpm, 34 hours; during the fermentation process, samples are taken every 2 hours, pH value is measured, and colony morphology is observed . When the number of spores reaches 5%, add the material once. When the number of spores reaches 90%, stop the fermentation, and observe whether it is a biological agent through micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com