Long-chain polycarboxylic acid water reducing agent

A technology of chain polycarboxylic acid and water-reducing agent, applied in the field of concrete admixtures, can solve the problems of complex production process of water-reducing agent, low cement adaptability, low water-reducing rate, etc. The effect of small loss of degree and improved early and late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

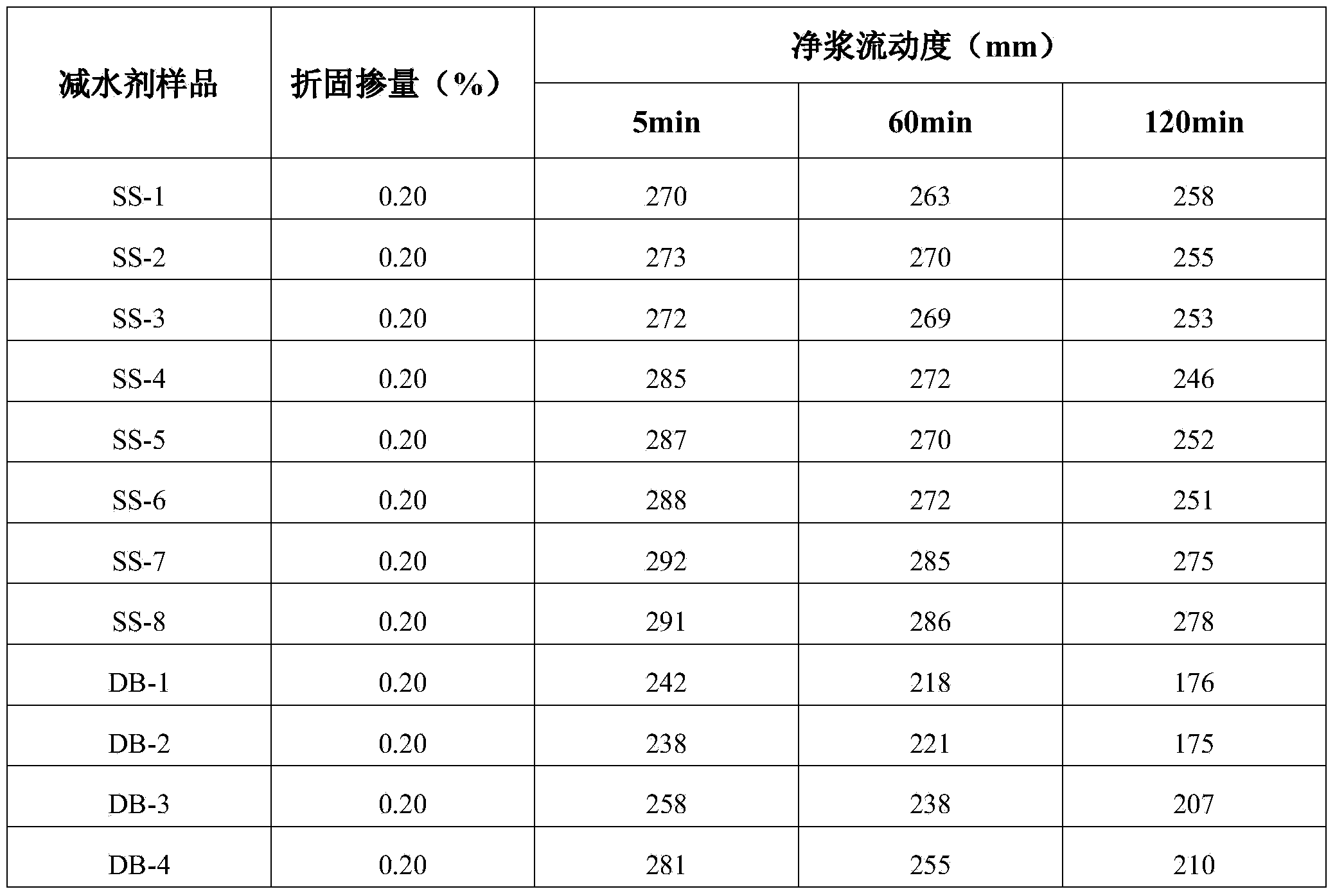

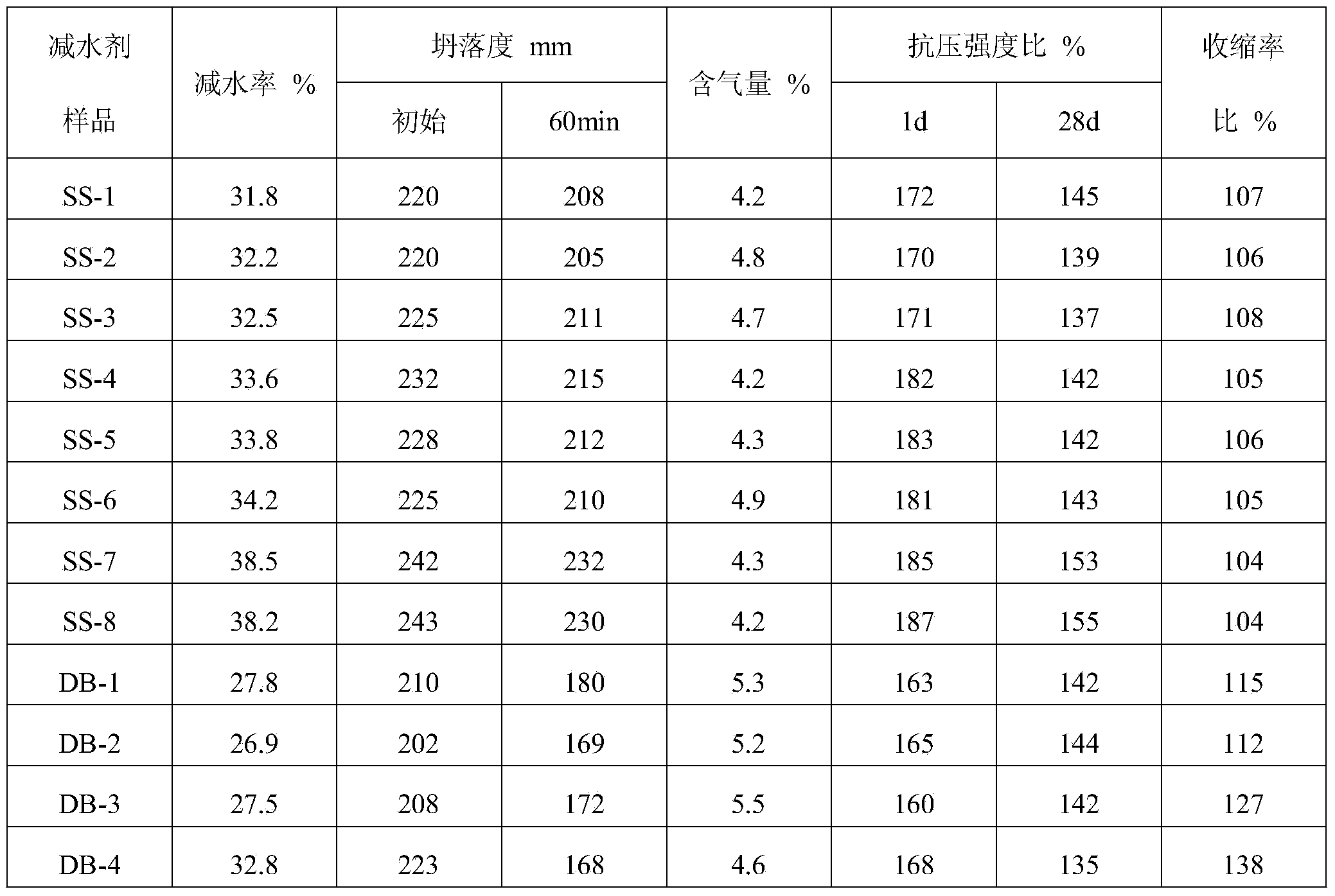

Examples

Embodiment 1

[0024] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 50% of the total mass of monomers, polyethylene glycol monomethyl ether methacrylate accounts for 10% of the total mass of monomers, acrylic acid accounts for 30% of the total mass of monomers, propylene Amide accounts for 10% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 7.2% as the dripping liquid II, wherein the amount of ammonium persulfate accounts for 2.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II dropwise to the flask at the same time, and the dropping time is controlled at 4 hours; after the dropwise addition is ...

Embodiment 2

[0026] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 30% of the total mass of the monomer, polyethylene glycol monomethyl ether methacrylate accounts for 20% of the total mass of the monomer, acrylic acid accounts for 40% of the total mass of the monomer, propylene Amide accounts for 10% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 7.2% as the dripping liquid II, wherein the amount of ammonium persulfate accounts for 2.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II dropwise to the flask at the same time, and the dropping time is controlled at 4 hours; after the dropwise add...

Embodiment 3

[0028] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 40% of the total mass of the monomer, polyethylene glycol monomethyl ether methacrylate accounts for 18% of the total mass of the monomer, acrylic acid accounts for 37% of the total mass of the monomer, propylene Amide accounts for 5% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 7.2% as the dripping solution II, wherein the amount of ammonium persulfate accounts for 2.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II dropwise to the flask at the same time, and the dropping time is controlled at 4 hours; after the dropwise ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com