Preparation method of aluminium-doped cerium-zirconium solid-solution polishing powder

A cerium-zirconium solid solution and polishing powder technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of surface scratches, increased surface roughness, and difficulty in forming solid solutions for polished workpieces with doped amounts, and achieve raw materials Inexpensive, uniform particle size, significant synergistic polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

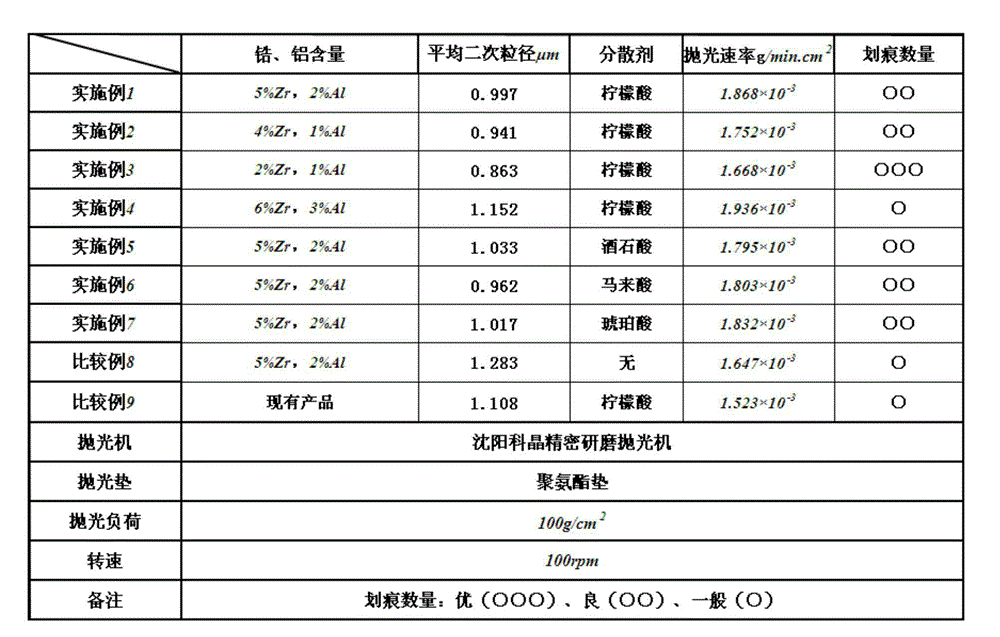

Examples

Embodiment 1

[0025] The specific preparation steps of this implementation are as follows:

[0026] (1) Preparation of colloidal solution:

[0027] ①. Disperse 9 g of pseudo-boehmite into 80 ml of pure water under high-speed stirring to obtain a solid-liquid mixed slurry for subsequent use;

[0028] 2. Slowly add 3 ml of hydrochloric acid with a mass fraction of 38% dropwise to the standby solid-liquid mixed slurry, and carry out peptization to obtain an aluminum hydroxide colloidal solution for subsequent use;

[0029] ③. Disperse 13.5 g of citric acid in the aluminum hydroxide colloidal solution, and mix well to obtain the colloidal solution A;

[0030] 2. Preparation of mixed system:

[0031] 1. 250 g of cerium carbonate and 11.2 g of zirconium carbonate are dissolved in hydrochloric acid with a mass fraction of 38% respectively, and the pH value of the solution is controlled between 1-1.5. After the dissolution is complete, cerium chloride solution and zirconium chloride solution are ...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, except that the content of zirconium is 4%, and the content of aluminum is 1%.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, except that the content of zirconium is 2%, and the content of aluminum is 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com