Preparation method of concentrated protein of cottonseeds and processing production line thereof

A technology for concentrated protein and dephenolized cottonseed protein is applied in the field of preparation of cottonseed protein concentrate, which can solve the problems of low protein content and toxin content, and achieve the effects of high carbohydrate content, good solubility and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

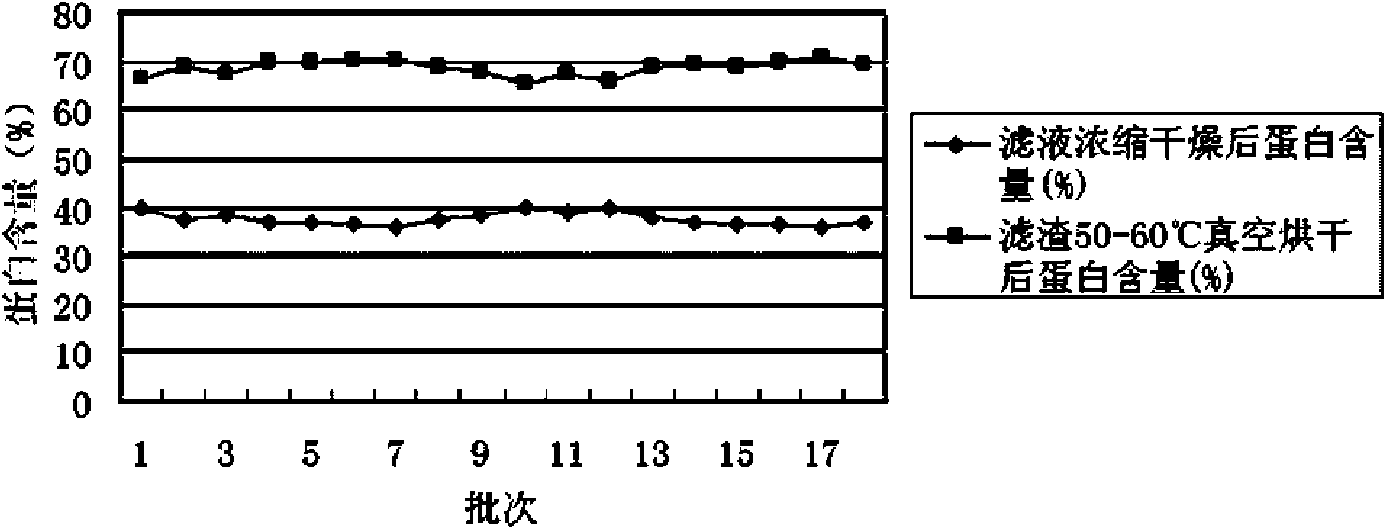

Examples

Embodiment

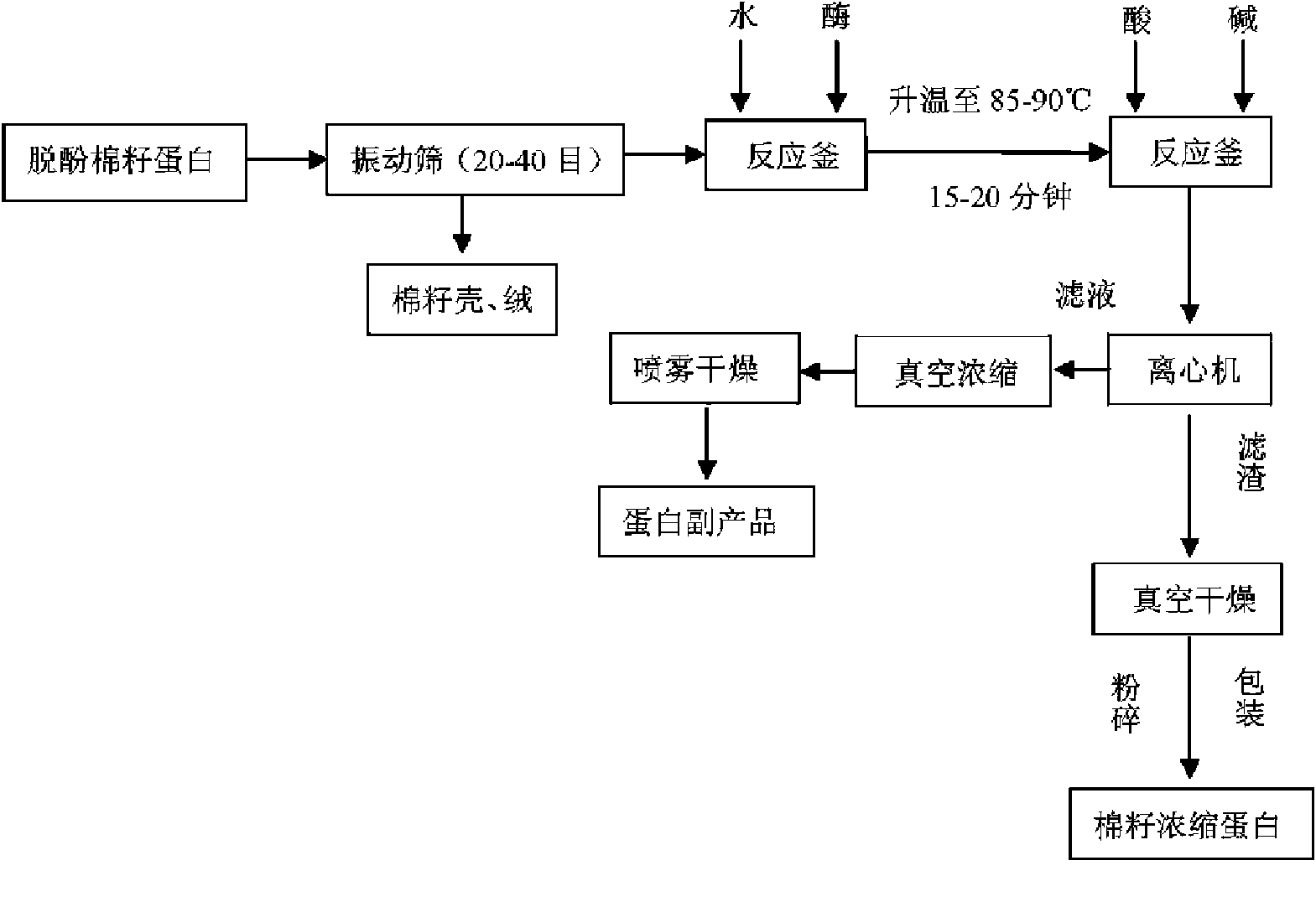

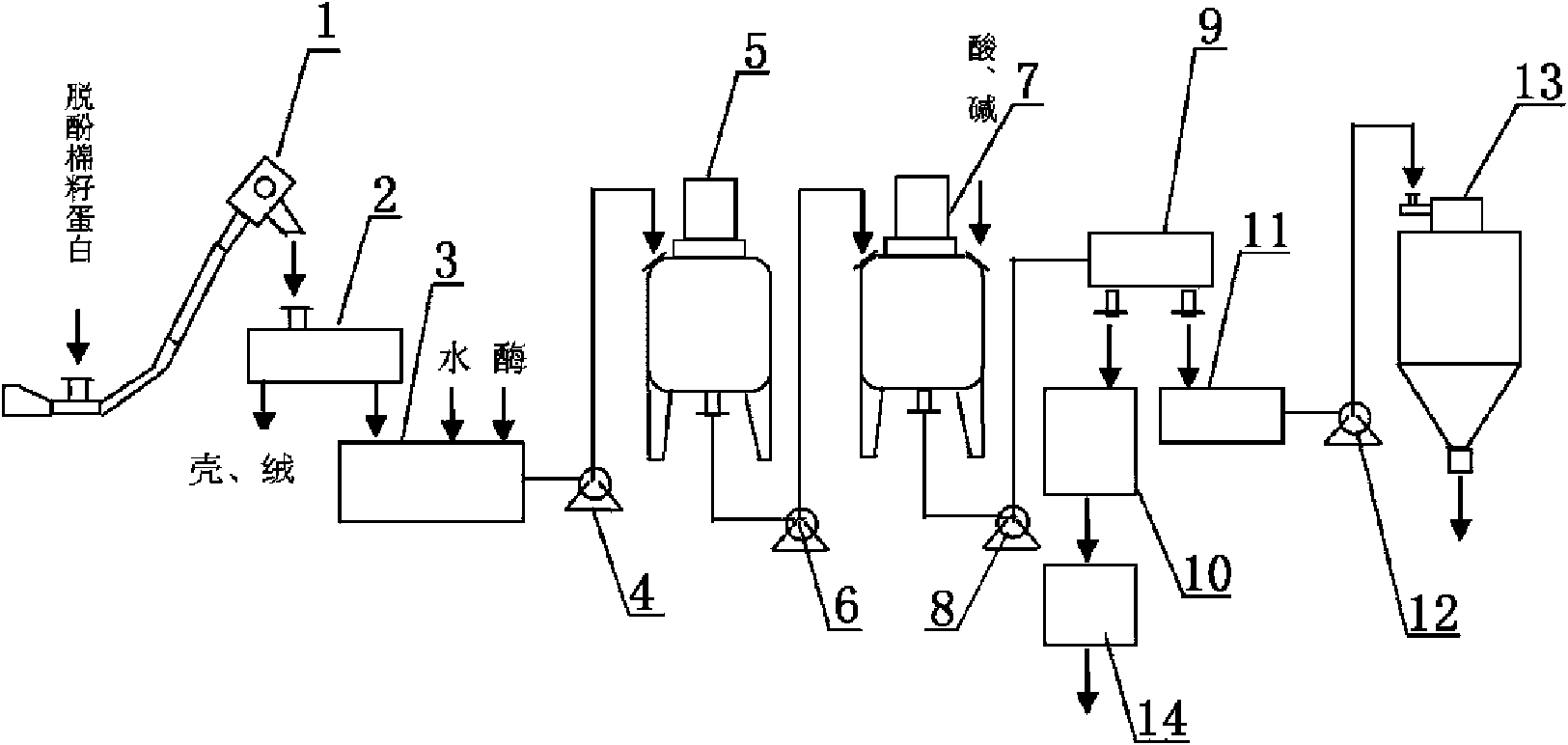

[0041] Embodiment, the method steps of this preparation functional protein peptide:

[0042] Step 1. Pretreating the dephenolized cottonseed protein raw material through a 20-40 mesh sieve to remove shells and velvet in the raw material; the used dephenolized cottonseed protein raw material is dephenolized cottonseed protein with a protein content ≥ 50%.

[0043] Step 2. Put the pretreated dephenolized cottonseed protein raw material into the enzymatic hydrolysis reaction kettle, add water and stir; the amount of water added in the enzymatic hydrolysis reaction kettle is 6 to 8 times the quality of the cottonseed protein raw material, and control The temperature of the material is 30-40°C.

[0044] Step 3. Add amylase, cellulase and pectinase combined non-protease in the enzymolysis reaction kettle, and the addition amount accounts for 0.5~0.6‰, 1.0~1.2‰ and 0.4~0.5% of the quality of dephenolized cottonseed protein raw material respectively ‰, after 1-3 hours of enzymatic hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com