Environment-friendly peroxyacetic acid disinfectant and preparation method and application thereof

A peracetic acid, green and environmentally friendly technology, applied in the field of medicine and chemical industry, to achieve the effect of no environmental pollution, simple operation, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the above-mentioned green environment-friendly peracetic acid disinfectant, comprising the following steps: taking each raw material according to the proportion;

[0038] a. Dissolving and reacting glacial acetic acid and citric acid to obtain homogeneous phase A;

[0039] b, hydrogen peroxide and boric acid are dissolved and reacted to obtain homogeneous phase B;

[0040] c. Mix the homogeneous phase A obtained in step a with the homogeneous phase B obtained in step b. After reacting at normal temperature, add sodium citrate and urea, stir again, and then stand for reaction at normal temperature to obtain peracetic acid disinfectant .

[0041] In order to solve the technical problems of traditional synthesis of peracetic acid, the present invention adopts physical and chemical technology to select compound weak acid to replace concentrated sulfuric acid for catalysis, and explores the optimal catalytic synthe...

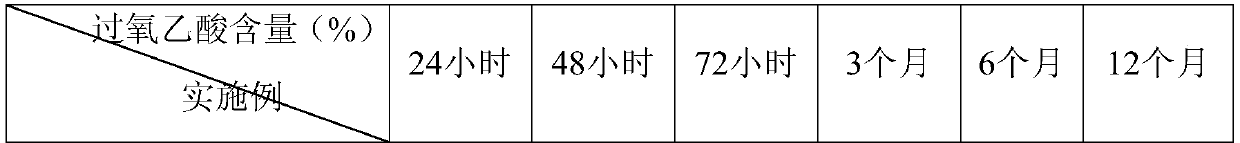

Embodiment 1

[0047] Add 50 mL of 99.0 wt% glacial acetic acid into a round bottom flask, add 1 g of citric acid catalyst, heat to 40-60 ° C, stir for 20-30 minutes, and react to form acetyl homogeneous phase A;

[0048] Add 50 mL of 30 wt% hydrogen peroxide into a round bottom flask, add 1 g of boric acid catalyst, heat to 40-60 ° C, stir for 20-30 minutes, and react to form acidic hydrogen peroxide homogeneous phase B;

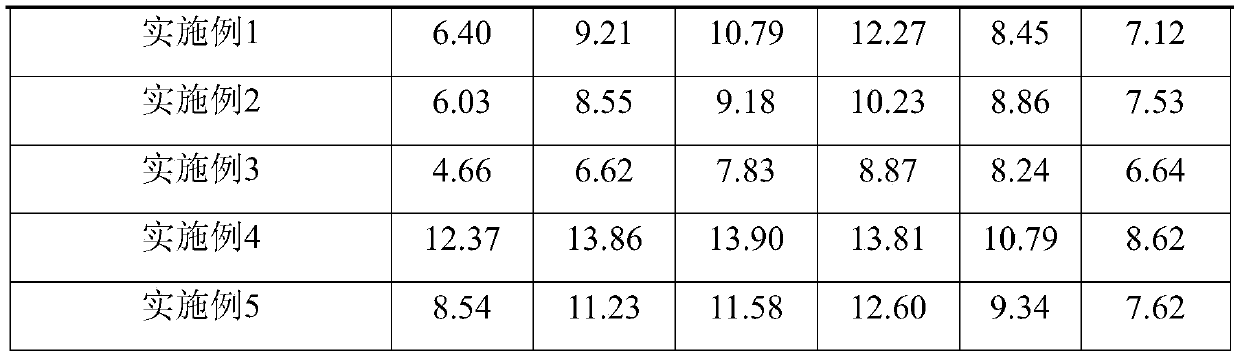

[0049] Add the above-mentioned homogeneous phase B into homogeneous phase A, stir for 20-30 minutes, then react at room temperature for 2-4 hours; The amount is 0.1% of the total material quality), stirred for 20 to 30 minutes, then left to react at room temperature for 24 to 72 hours to obtain peracetic acid disinfectant; adopt the typical method "Disinfection Technical Specifications" experimental technical specifications to measure, its The mass concentration of peracetic acid is 5-12%.

Embodiment 2

[0051] Add 50 mL of 99.0 wt% glacial acetic acid into a round bottom flask, add 2 g of citric acid catalyst, heat to 40-60 ° C, stir for 20-30 minutes, and react to form acetyl homogeneous phase A;

[0052] Add 100 mL of 30 wt% hydrogen peroxide into a round bottom flask, add 2 g of boric acid catalyst, heat to 40-60 ° C, stir for 20-30 minutes, and react to form acidic hydrogen peroxide homogeneous phase B;

[0053] Add the above-mentioned homogeneous phase B into homogeneous phase A, stir for 20-30 minutes, then react at room temperature for 2-4 hours; The amount is 0.2% of the total material quality), stirred for 20 to 30 minutes, and then left to stand at room temperature for 24 to 72 hours to obtain peracetic acid disinfectant; adopt the typical method "Disinfection Technical Specifications" experimental technical specifications to measure, and its The mass concentration of peracetic acid is 5-10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com