Preparation method of high-reflectivity flaky pearlescent pigment bismuth oxychloride

A pigment bismuth oxychloride, high reflectivity technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve environmental pollution, long production cycle, complex operation of synthesizing flake bismuth oxychloride crystals and other issues, to achieve the effect of no pollution to the environment, short production cycle, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

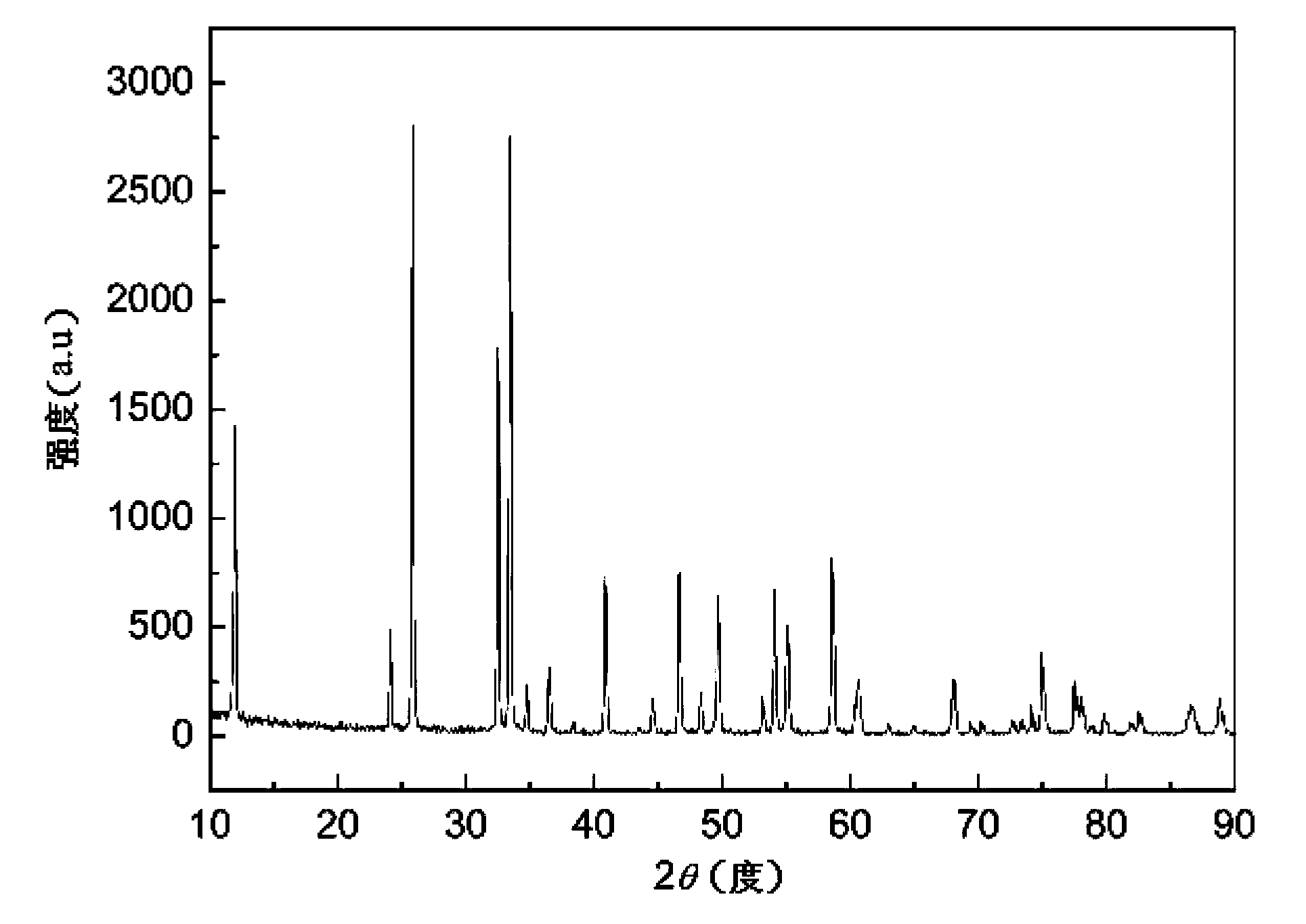

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of high-reflectance flaky pearlescent pigment bismuth oxychloride of this embodiment, carry out according to the following steps: one, bismuth nitrate is dissolved in the nitric acid solution that mass percentage content is 50~65%, then Dilute with water until the concentration of bismuth nitrate solution is 0.005-200g / L to obtain bismuth nitrate solution; 2. Dissolve sodium lauryl sulfate in water at 0-100°C to obtain dodecyl sulfate with a concentration of 0.0001-20g / L Sodium sulfate solution; 3. Add sodium lauryl sulfate solution to the bismuth nitrate solution in step 1 at 0-70°C, add water to dilute until no precipitation occurs, and obtain a suspension solution; Add the nitric acid that the mass percent content is 65% to the precipitate completely disappears in the suspended solution; Five, the preparation concentration is the magnesium chloride aqueous solution of 0.1~100g / L, then pours in the solution after the nitr...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the nitric acid solution in Step 1 is 50-65%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, sodium lauryl sulfate is dissolved in water at 60-80°C to obtain dodecyl sulfate with a concentration of 0.002-2g / L sodium sulfate solution. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com