Efficient adsorbent based on ginkgo leaves and preparation method thereof

An adsorbent and ginkgo leaf technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve environmental impact and other problems, and achieve high efficiency, low energy consumption, and simple and easy-to-operate preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Ginkgo biloba is crushed into powder in a high-speed pulverizer, crosses a 100-mesh standard mesh sieve, and selects the leaf powder in the 100-mesh size range for subsequent use;

[0021] (2) Ginkgo biloba powder is repeatedly washed until the lotion is clarified with deionized water;

[0022] (3) Soak the powder obtained in step (2) with a mixed solution of sodium carbonate and sodium bicarbonate with a mass fraction of 3%, and stir and keep it warm at 60° C. at 30 rpm for 1 hour;

[0023] (4) The powder obtained in step (3) is repeatedly washed several times with 1% dilute hydrochloric acid sulfuric acid mixed acid;

[0024] (5) Wash the powder washed with 1% dilute hydrochloric acid and sulfuric acid mixed acid solution in step (4) to neutrality with deionized water;

[0025] (6) Put the powder washed in step (5) into an oven, and dry at 60°C for 12 hours;

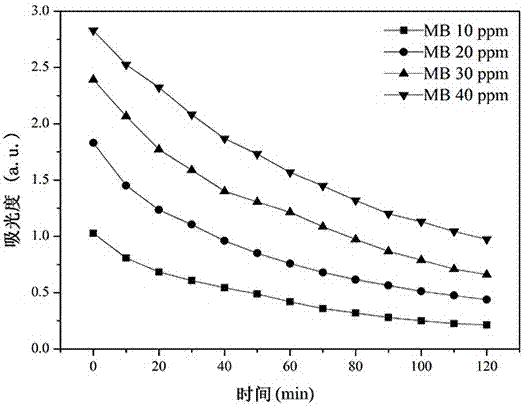

[0026] Adsorption performance evaluation was carried out at room temperature: 0.02 g of adsorbent was a...

Embodiment 2

[0028] (1) Ginkgo biloba is crushed into powder in a high-speed pulverizer, crosses a 40 mesh standard mesh sieve, and selects the leaf powder of the 40 mesh size range for subsequent use;

[0029] (2) Ginkgo biloba powder is repeatedly washed until the lotion is clarified with deionized water;

[0030] (3) Soak the powder obtained in step (2) with a mixed solution of sodium hydroxide and potassium hydroxide with a mass fraction of 5%, and stir and keep it warm at 70° C. at 25 rpm for 3 hours;

[0031] (4) The powder obtained in step (3) is repeatedly washed several times with 2% dilute sulfuric acid;

[0032] (5) The powder washed with 2% dilute sulfuric acid in step (4) is washed to neutrality with deionized water;

[0033] (6) Put the powder washed in step (5) into an oven, and dry at 50°C for 24 hours;

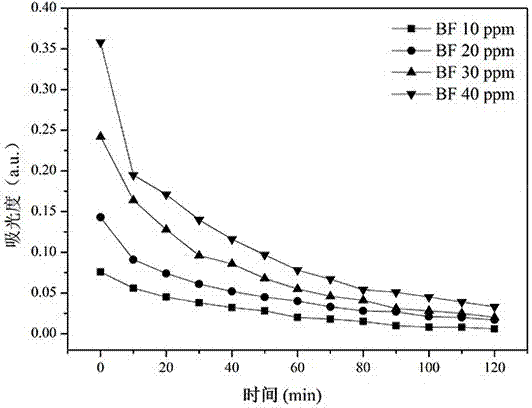

[0034] Adsorption performance evaluation was carried out at room temperature: 0.02 g of adsorbent was added to 20 mL of basic fuchsin (BF) solutions with initial concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com