Polycarboxylate cement grinding aid and preparation method thereof

A technology of cement grinding aid and polycarboxylate, which is applied in the field of cement process admixtures, can solve problems such as high cost and unstable system, and achieve the effects of low cost, serious dependence and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

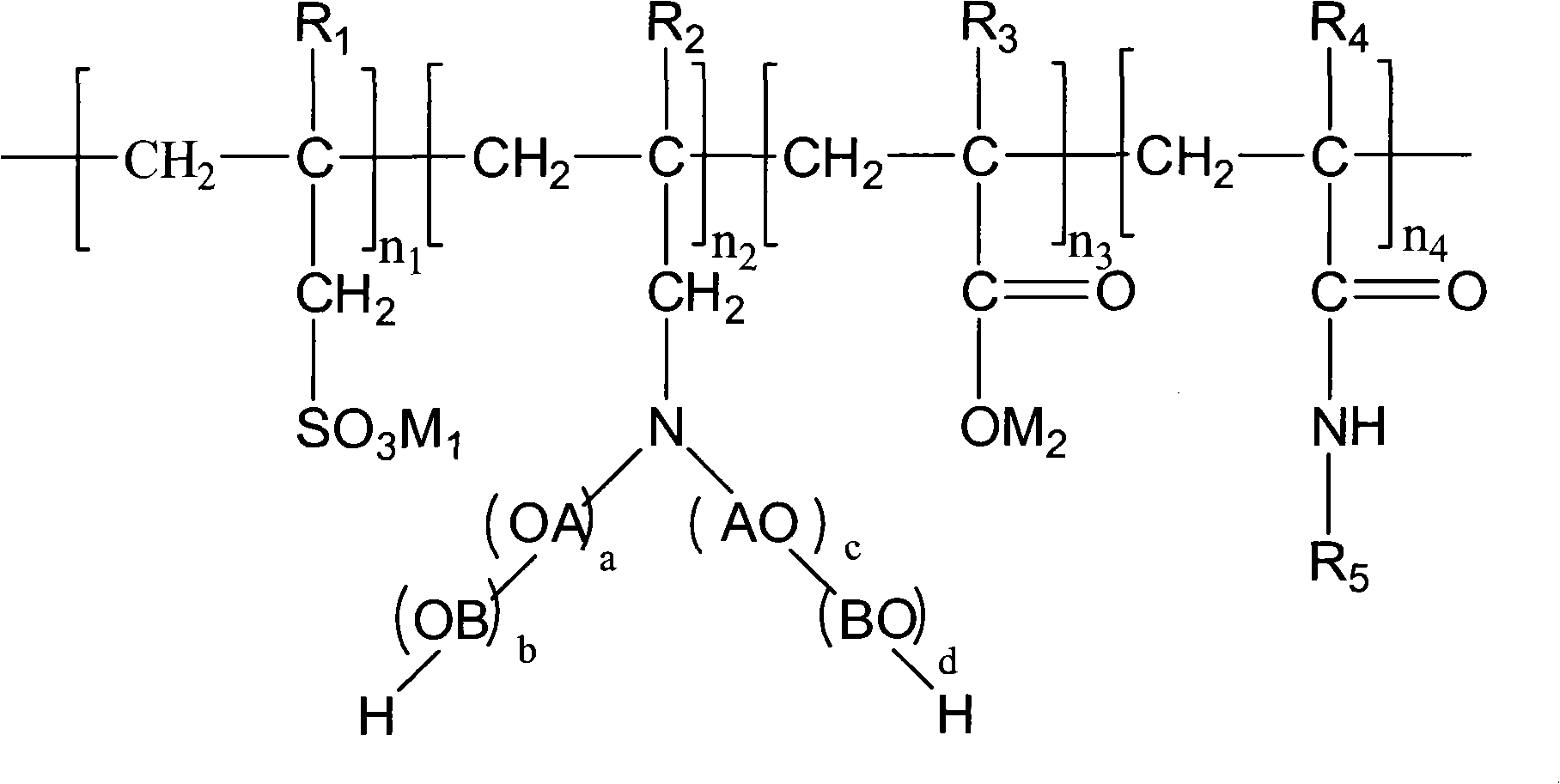

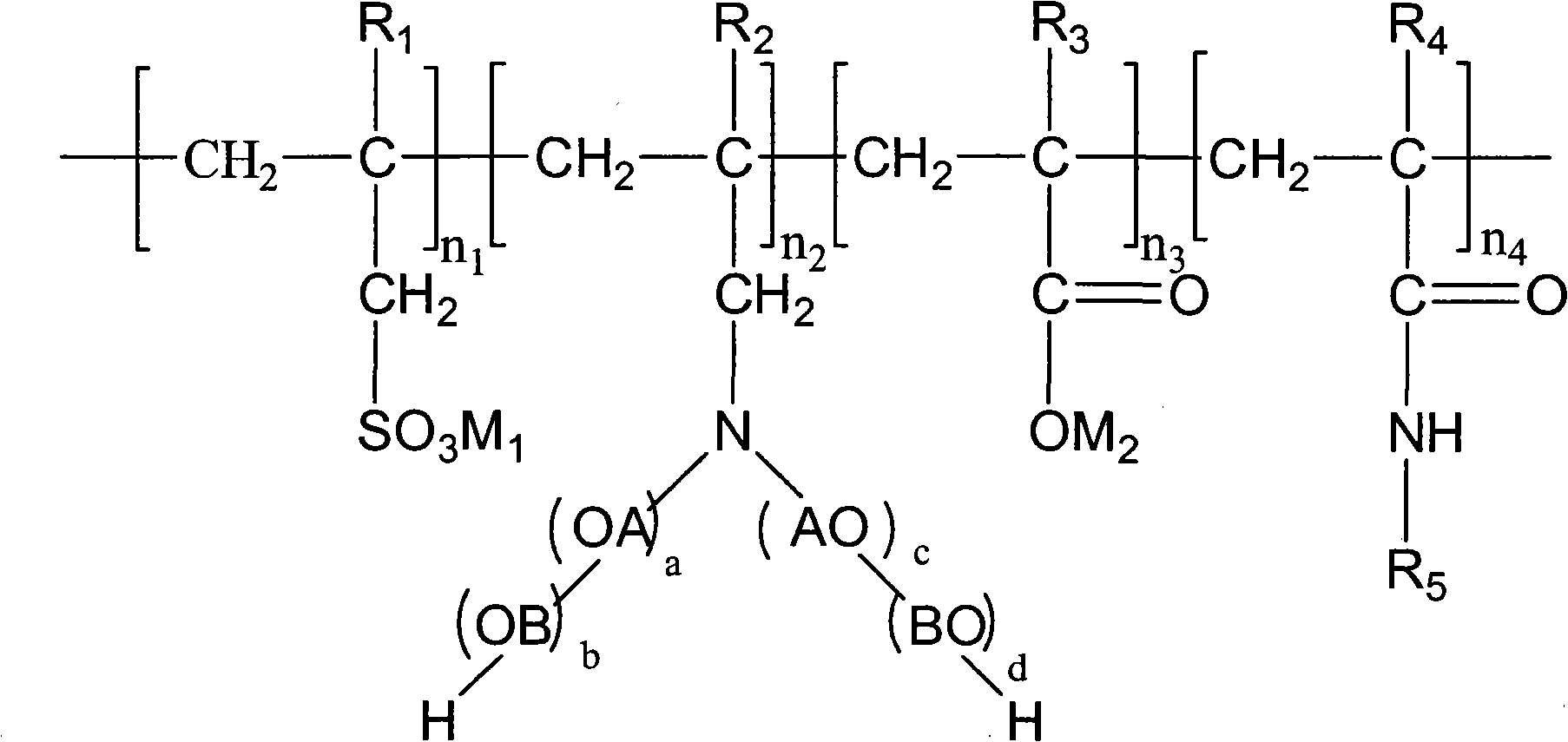

Method used

Image

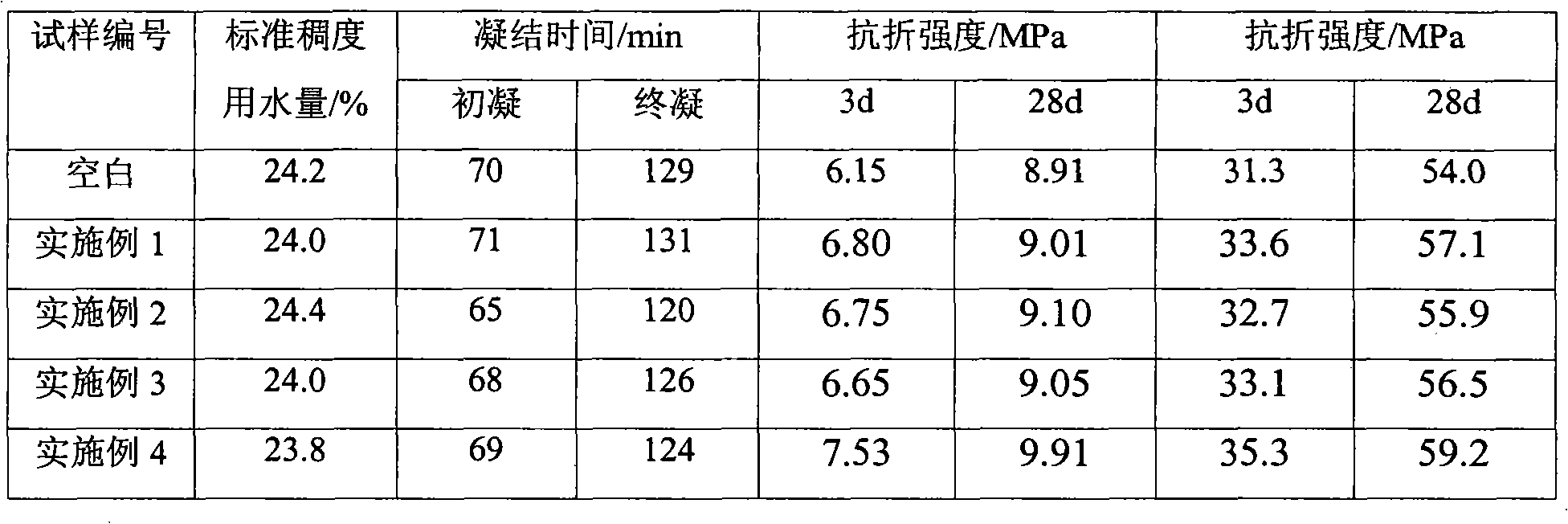

Examples

Embodiment 1

[0023] Add 0.1 part of MAS and a certain amount of deionized water into a four-neck flask, add 0.5 part of NPEG (molecular weight 600), 0.1 part of AMPS and 0.3 part of MAA into deionized water to form a monomer solution, and use 1% of the total amount of monomer Potassium persulfate was added to deionized water to prepare an initiator solution. When the temperature reached 75°C, the initiator solution was added dropwise. The monomer solution was added dropwise 5 minutes later than the initiator solution. After 5 hours, the dropwise addition was completed, and the temperature was raised to 90°C. Keep warm for 1 hour. Cooling is neutralized with 40% sodium hydroxide solution to obtain polymer A solution, and 5% TEA is added to the solution to obtain the polycarboxylate cement grinding aid 1.

Embodiment 2

[0025] Add a certain amount of deionized water in a four-neck flask, add 0.6 part of NPEG (molecular weight 400), 0.15 part of AAM and 0.25 part of MAA into deionized water to form a monomer solution, and use ammonium persulfate accounting for 1.5% of the total monomer Add deionized water to prepare an initiator solution. When the temperature reaches 70°C, start to add the initiator solution dropwise. The monomer solution is added dropwise 5 minutes later than the initiator solution. After 4 hours, the dropwise addition is completed, and the temperature is raised to 95°C and kept for 2 hours. Cooling is neutralized with 40% sodium hydroxide solution to obtain polymer A solution, and 5% TIPA is added to the solution to obtain the polycarboxylate cement grinding aid 2.

Embodiment 3

[0027] Add 0.15 parts of SAS and a certain amount of deionized water into a four-neck flask, add 0.55 parts of NPEG (molecular weight 400), 0.25 parts of MAM and 0.25 parts of AA into deionized water to form a monomer solution, and use 1.5% of the total amount of monomers Potassium persulfate was added to deionized water to prepare an initiator solution. When the temperature reached 80°C, the initiator solution was added dropwise. The monomer solution was added dropwise 5 minutes later than the initiator solution. After 4 hours, the dropwise addition was completed, and the temperature was raised to 90°C. Keep warm for 1 hour. Cool and neutralize the solution with 40% sodium hydroxide and ammonia water to obtain polymer A solution, add 4% TEA to the solution to obtain the polycarboxylate cement grinding aid 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com