A kind of vortex beam detector and its preparation method

A vortex beam and detector technology, applied in optical device exploration, instrumentation, optics, etc., can solve problems such as damage, severe wavelength dependence, and crosstalk modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

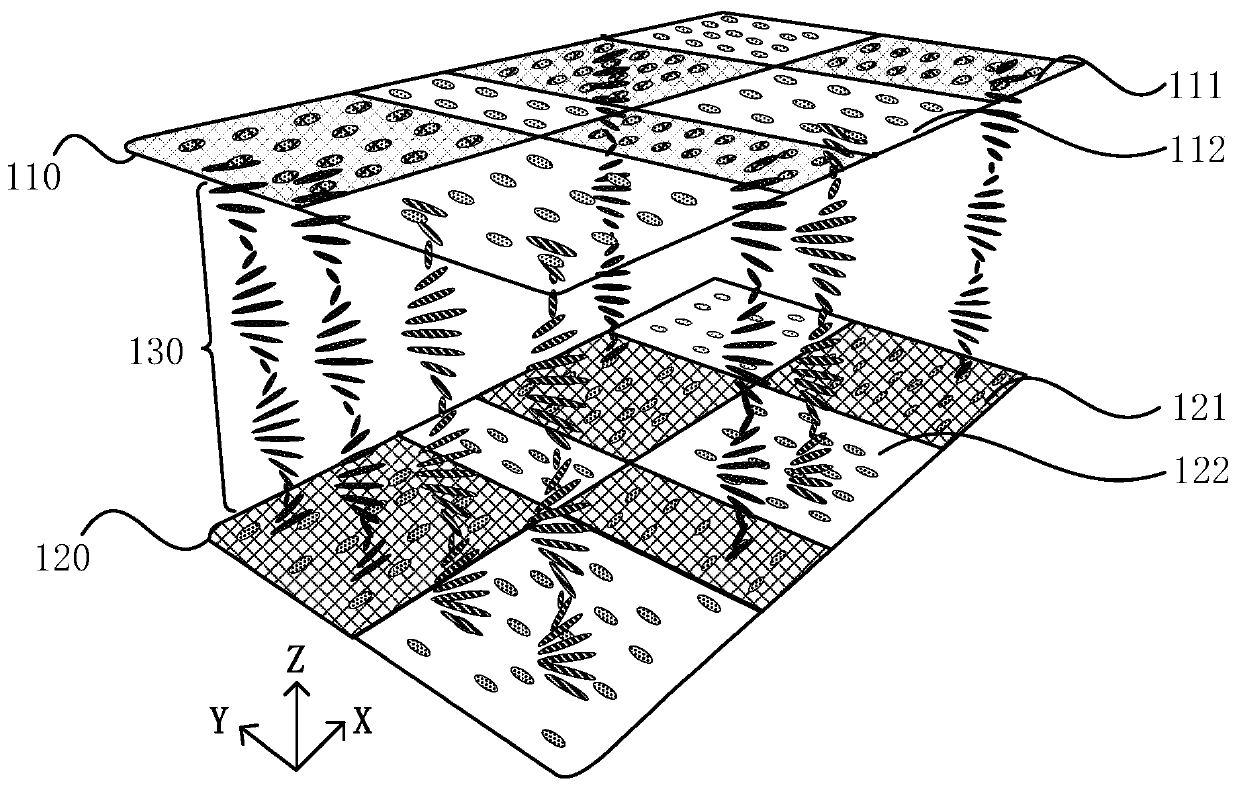

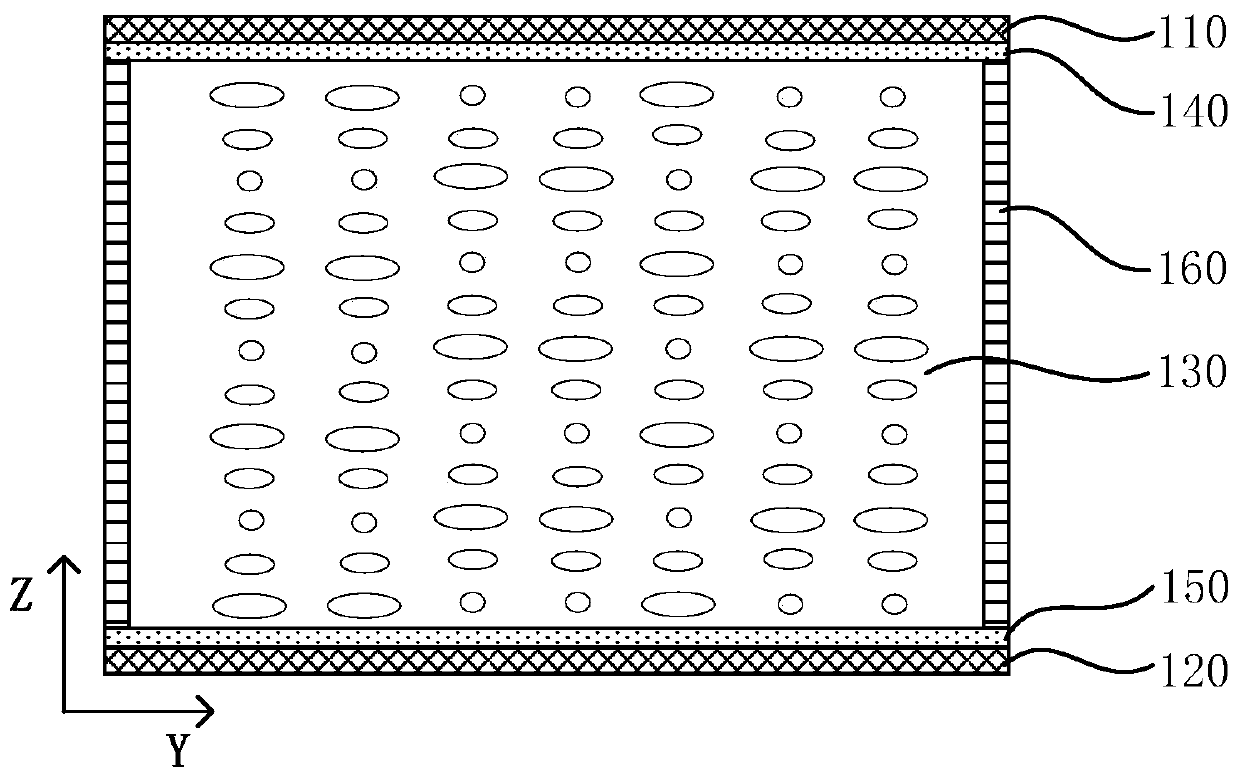

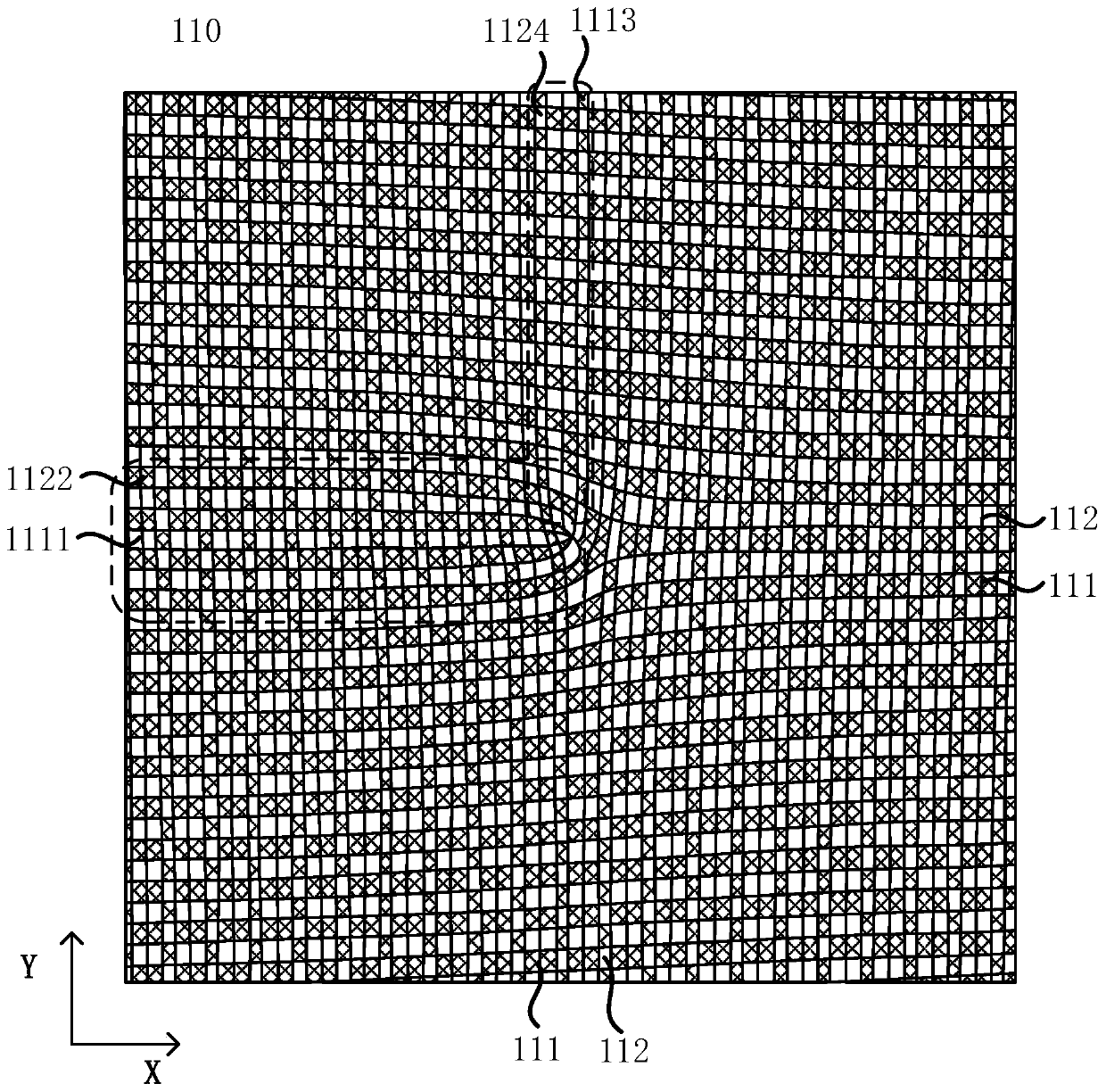

[0047] figure 1 It is a schematic diagram of a three-dimensional structure of a vortex beam detector provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of a Y-Z side structure of a vortex beam detector provided in Embodiment 1 of the present invention. see figure 1 with figure 2 , the vortex beam detector includes:

[0048] The first substrate 110 and the second substrate 120 arranged oppositely; the cholesteric liquid crystal layer 130 between the first substrate 110 and the second substrate 120; the side of the first substrate 110 close to the second substrate 120 is formed with a first orientation Film 140; the first alignment film 140 comprises a first alignment region 111 and a second alignment region 112, and the alignment film molecular directors of the first alignment region 111 and the second alignment region 112 are arranged orthogonally; along the first direction ( figure 1 In the X direction), the first alignment region 111 ...

Embodiment 2

[0080] Figure 12 It is a schematic flow chart of a method for preparing a vortex beam detector provided in Embodiment 2 of the present invention, which is used to prepare the vortex beam detector provided in Embodiment 1 above. See Figure 12 , the preparation method comprises:

[0081] S510, providing a first substrate and a second substrate, where the first substrate and the second substrate are arranged opposite to each other.

[0082] Wherein, the first substrate and the second substrate can adopt flexible substrates or rigid substrates with high light transmittance (greater than or equal to 85%).

[0083] Exemplarily, the material of the first substrate and the second substrate may include quartz glass or ordinary glass, and the thickness of the substrate may be 1-2 millimeters (mm).

[0084] S520, forming a first alignment film on a side of the first substrate close to the second substrate, and forming a second alignment film on a side of the second substrate close to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com