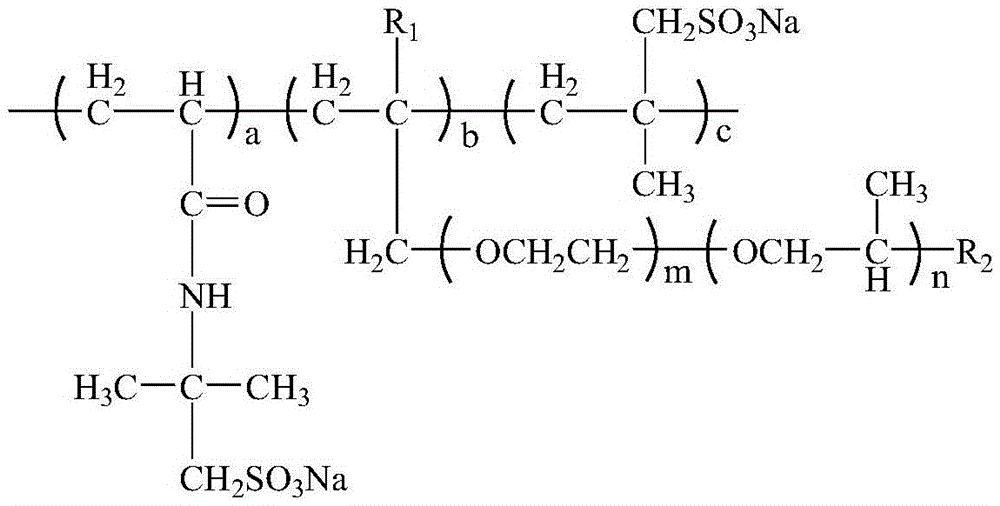

A kind of polymer sulfonate, its preparation method and its application in cement grinding aid

A sulfonate and polymer technology, applied in the field of polymer sulfonate, can solve the problems of inability to guarantee the stability of component distribution and poor product stability, achieve clear molecular structure design, low production equipment requirements, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

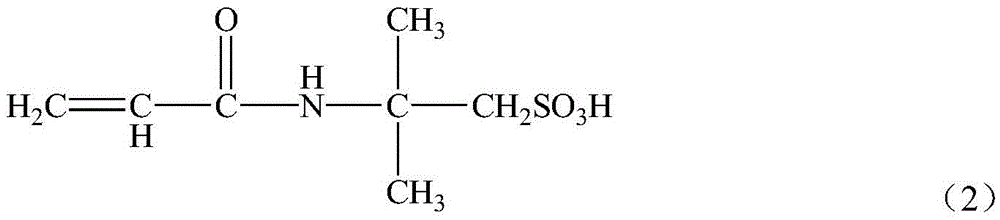

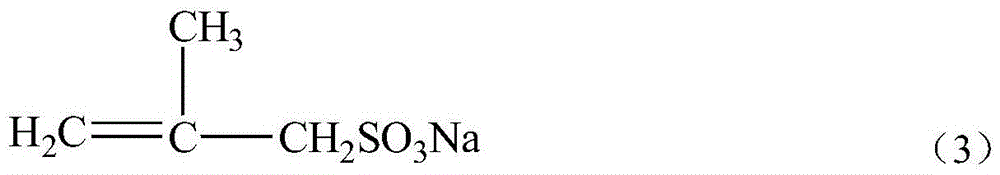

Method used

Image

Examples

Embodiment 1

[0039] Add 300 kg of allyl polyethylene glycol with a molecular weight of 1000 into a reactor equipped with a condensation splitter device, add 350 kg of water, stir, and raise the temperature to 60°C. Weigh 15.8kg for SMAS, 51.75kg for AMPS, add 120kg of water to dissolve and make monomer solution. Weigh 29.4 kg of ammonium persulfate and add 125.4 kg of water to form an initiator solution; simultaneously add the monomer solution and the initiator solution dropwise, and the dropwise addition is completed in 4 hours. Insulate at 85°C for 2 hours, cool down, and cool to 45°C to obtain the product.

[0040] Small grinding experiment data:

[0041]

[0042] Note: 1. The clinker is provided by Tongling Conch: 3d compressive strength: 30MPa; 28d compressive strength: 62MPa;

[0043] 2. Small mill grinding is 30 minutes.

Embodiment 2

[0045] Add 270 kg of polyoxyethylene (oxypropylene) alcohol ether (EO number 12, PO number 7) with a molecular weight of 1000 into a reactor equipped with a condensation and splitter device, add 300 kg of water, stir, and raise the temperature to 65°C. Weigh 55.9kg of AMPS, add 120kg of water to dissolve and make a monomer solution. Weigh 13.03 kg of ammonium persulfate and add 88 kg of water to form an initiator solution; simultaneously add the monomer solution and the initiator solution dropwise, and the addition is completed in 4 hours. Insulate at 95°C for 2 hours, cool down, and cool to 45°C to obtain the product.

[0046] Small grinding experiment data:

[0047]

[0048] Note: 1. The clinker is provided by Tongling Conch, 3d compressive strength: 30MPa; 28d compressive strength: 62MPa;

[0049] 2. Small mill grinding is 30 minutes.

Embodiment 3

[0051]Add 270kg of polyoxyethylene (oxypropylene) alcohol ether with a molecular weight of 1000 (EO number 12, PO number 7) and SMAS42.7kg into a reactor equipped with a condensation and splitter device, add 315kg of water, stir, and heat up to 65°C . Weigh 31.3 kg of ammonium persulfate and add 200 kg of water to form an initiator solution; add the initiator solution dropwise, and the addition is completed in 4 hours. Insulate at 95°C for 2 hours, cool down, and cool to 45°C to obtain a product with a solid content of 40%.

[0052] Small grinding experiment data:

[0053]

[0054] Note: 1. The clinker is provided by Tongling Conch: 3d compressive strength: 30MPa; 28d compressive strength: 62MPa;

[0055] 2. Small mill grinding is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com