Eco-friendly shield tail sealing grease as well as preparation method and application thereof

A technology of sealing grease and shield tail seal, applied in the direction of lubricating composition, etc., can solve the problems of biodegradability to be further improved, poor biodegradability, unable to meet environmental protection, etc., to achieve good consistency and pumpability, adhesion Excellent performance, good water pressure resistance and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

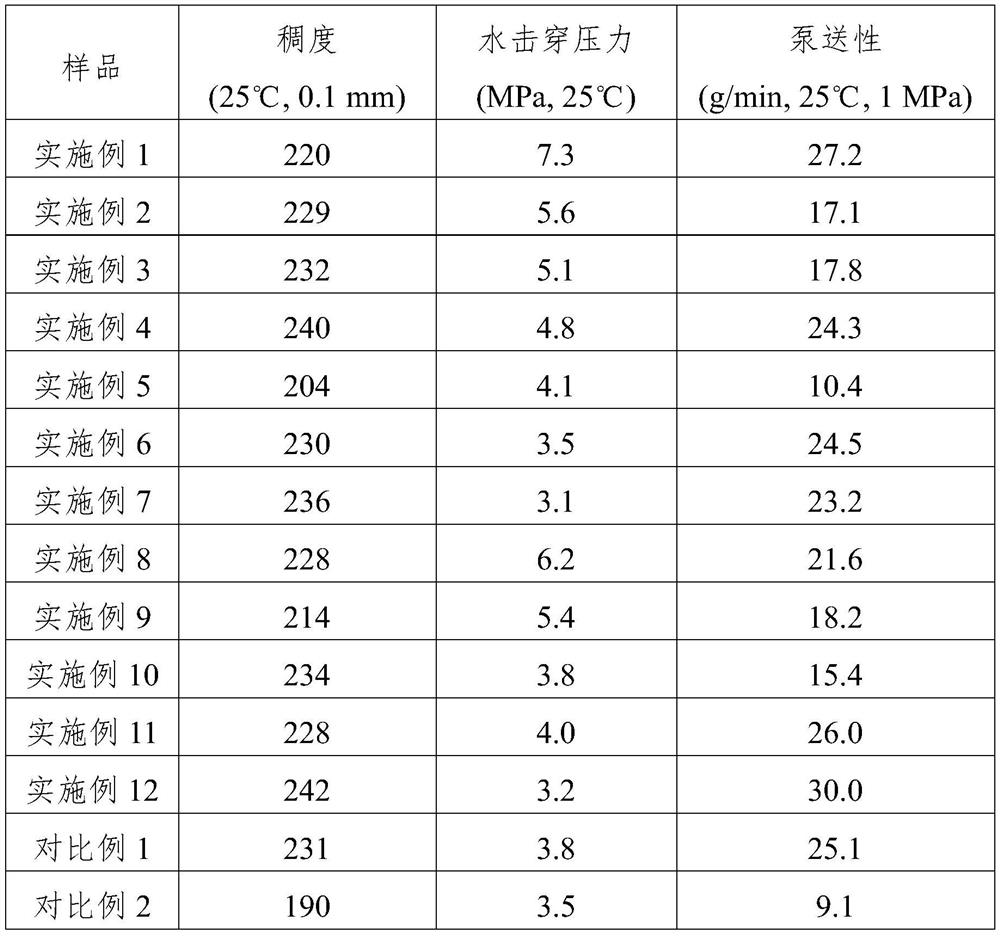

Examples

Embodiment 1

[0047] This embodiment provides an eco-friendly shield tail sealing grease and a preparation method thereof.

[0048] The sealing grease consists of 32kg epoxy soybean oil, 5kg polyisobutylene, 5kg guar gum, 3kg organic montmorillonite, 2kg vinyl tris (β-methoxyethoxy) silane, 3.5kg cellulose fiber, 3.4kg cotton fiber, Composition of straw powder 10kg, calcium carbonate 36kg, OBPA antifungal agent 0.1kg.

[0049] The preparation method is as follows:

[0050] (1) Epoxidized soybean oil, polyisobutylene and guar gum were mixed and stirred for 30min at a temperature of 80°C;

[0051] (2) Mix the mixture obtained in step (1) with organic montmorillonite in a kneader for 5 minutes at 70°C, then add vinyl tris(β-methoxyethoxy)silane, straw powder, carbonic acid Calcium and OBPA antifungal agent continue to stir for 5 minutes, and finally add cellulose fiber and cotton fiber and continue to mix and stir for 75 minutes;

[0052] (3) Pass the mixture obtained in step (2) through a ...

Embodiment 2-5

[0054] This embodiment provides an eco-friendly shield tail sealing grease and a preparation method thereof.

[0055] The only difference with Example 1 is that in this example, the amount of organic montmorillonite added is 2.5kg (Example 2), 2kg (Example 3), 1kg (Example 4), 5kg (Example 5 ).

Embodiment 6-9

[0057] This embodiment provides an eco-friendly shield tail sealing grease and a preparation method thereof.

[0058] The only difference with Example 1 is that in this example, epoxidized soybean oil is replaced by rapeseed oil (Example 6), palm oil (Example 7), industrial soybean oil (Example 8), chicken oil (Example 9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com