Preparation method of high performance polycarboxylate water reducer

A technology of polycarboxylic acid series and water reducing agent, applied in the field of building materials, can solve the problems of low adaptability of cement, complex production process, low water reducing rate, etc. Effects of Early and Late Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

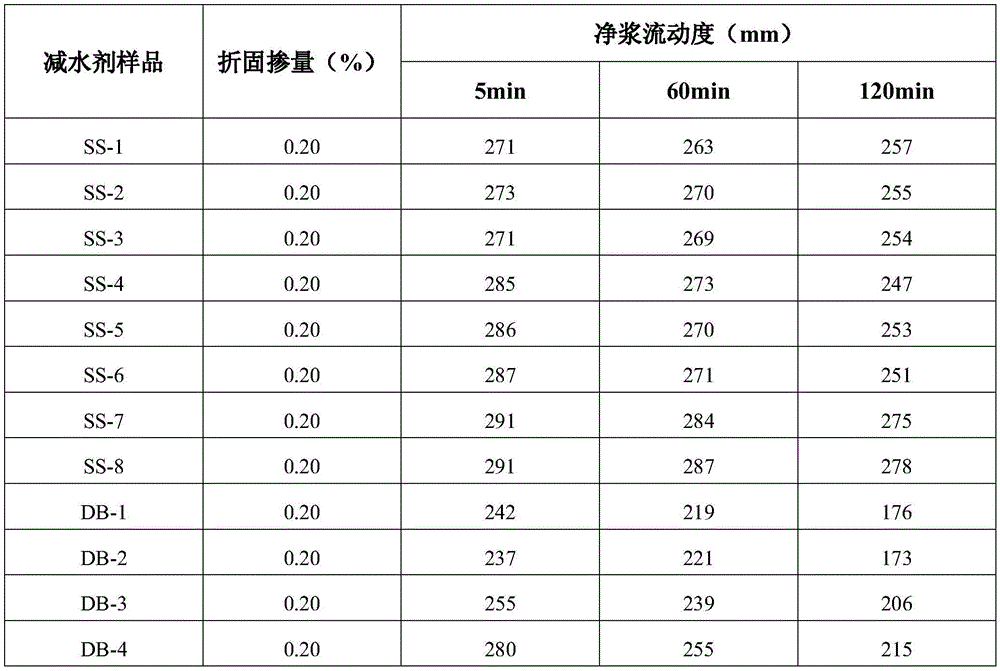

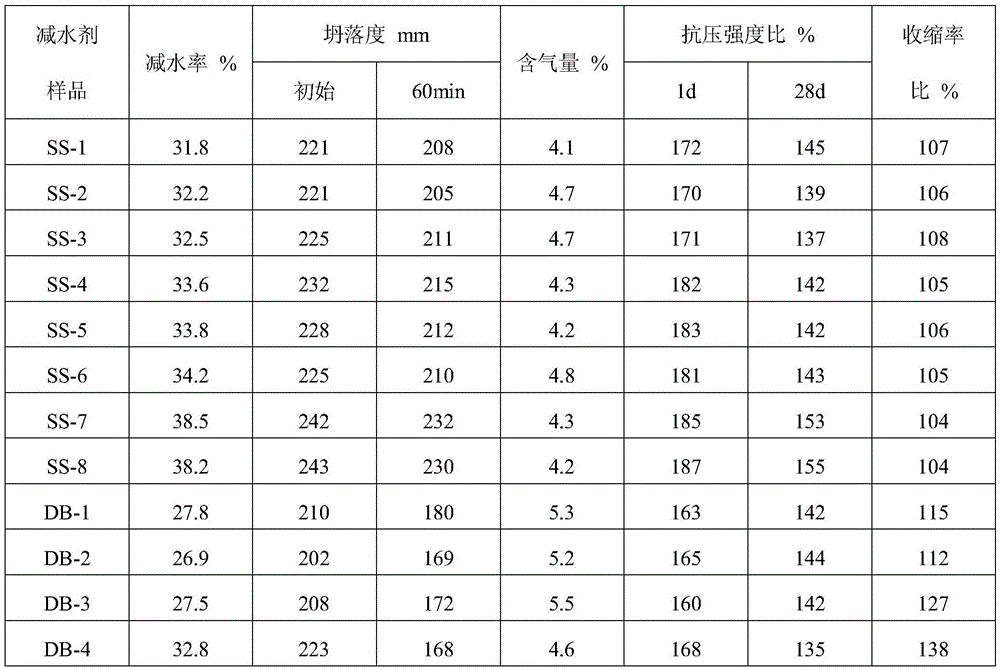

Examples

Embodiment 1

[0026] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 50% of the total mass of monomers, polyethylene glycol monomethyl ether methacrylate accounts for 10% of the total mass of monomers, acrylic acid accounts for 30% of the total mass of monomers, propylene Amide accounts for 10% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 8.0% as the dripping solution II, wherein the amount of ammonium persulfate accounts for 1.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II dropwise to the flask at the same time, and the dropping time is controlled at 4 hours; after the dropwise addition i...

Embodiment 2

[0028] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 30% of the total mass of the monomer, polyethylene glycol monomethyl ether methacrylate accounts for 20% of the total mass of the monomer, acrylic acid accounts for 40% of the total mass of the monomer, propylene Amide accounts for 10% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 8.0% as the dripping solution II, wherein the amount of ammonium persulfate accounts for 1.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II to the flask at the same time, and the dropwise addition time is controlled at 4 hours; after the dropwise a...

Embodiment 3

[0030] Add 50g of water into a 250mL four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and raise the temperature in the water bath to 80°C; dissolve each monomer in 3 times the water according to the ratio as the dripping liquid I , wherein: allyl polyethylene glycol accounts for 40% of the total mass of the monomer, polyethylene glycol monomethyl ether methacrylate accounts for 18% of the total mass of the monomer, acrylic acid accounts for 37% of the total mass of the monomer, propylene Amide accounts for 5% of the total mass of the monomer; ammonium persulfate is taken according to the amount and dissolved in water to form a solution with a mass fraction of 8.0% as the dripping liquid II, wherein the amount of ammonium persulfate accounts for 1.5% of the total mass of the monomer; Add dropwise solution I and dropwise solution II to the flask at the same time, and the dropwise addition time is controlled at 4 hours; after the dropwise addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com