Method for preparing flake-shaped MWCNTs/Cu composite powder with small particle size

A technology of composite powder and small particle size, applied in the direction of nanotechnology, can solve the problems of complex process, difficult industrial production, high cost, etc., and achieve the effect of short process flow and no industrial waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preparing small-diameter flaky MWCNTs / Cu composite powders has the following specific steps:

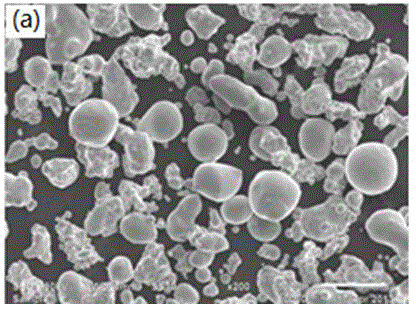

[0025] Step 1. First, mix 2.0g of MWCNTs and absolute ethanol evenly, then perform ultrasonic dispersion for 0.5h, and then perform suction filtration to control the mass ratio of MWCNTs and absolute ethanol in MWCNTs to 1:2; the purity of MWCNTs is greater than 95wt.%, and the outer diameter is 10nm and the length is 5μm, such as figure 1 Shown; The mass ratio of absolute ethanol addition to MWCNTs is 10:1;

[0026] Step 2. Add grinding balls, 194g of spherical atomized copper powder with a particle size of 80μm, and 6.0g of MWCNTs treated in step 1 (control the mass fraction of MWCNTs in MWCNTs / Cu composite powder to be 3%) into the horizontal high-energy stirring ball mill in turn Among them, the grinding ball material of the horizontal high-energy stirring ball mill is bearing steel, the size is Ф5mm, and then the chamber is sealed and filled with argon 3 t...

Embodiment 2

[0028] The method for preparing small-diameter flaky MWCNTs / Cu composite powders has the following specific steps:

[0029] Step 1. First, mix 4.0g MWCNTs and absolute ethanol evenly, then perform ultrasonic dispersion for 1 hour, and then perform suction filtration to control the mass ratio of MWCNTs and absolute ethanol in MWCNTs to 1:2.25; the purity of MWCNTs is greater than 95wt.%, and the outer diameter is 10nm with a length of 5μm, such as figure 1 Shown; The absolute ethanol addition is 50:1 with the mass ratio of MWCNTs;

[0030] Step 2. Add grinding balls, 120g spherical atomized copper powder with a particle size of 80μm, and MWCNTs treated in step 1 (control the mass fraction of MWCNTs in MWCNTs / Cu composite powder to be 3%) into the horizontal high-energy stirring ball mill in sequence , the material of the grinding balls in the horizontal high-energy stirring ball mill is bearing steel, the size is Ф5mm, and then the chamber is sealed and filled with argon gas a...

Embodiment 3

[0032] The method for preparing small-diameter flaky MWCNTs / Cu composite powders has the following specific steps:

[0033] Step 1. First, mix 5.0g of MWCNTs and absolute ethanol evenly, then perform ultrasonic dispersion for 2 hours, and then perform suction filtration to control the mass ratio of MWCNTs and absolute ethanol in MWCNTs to 1:1; the purity of MWCNTs is greater than 95wt.%, and the outer diameter is 70nm , with a length of 30 μm, such as figure 1 Shown; The absolute ethanol addition is 5:1 with the mass ratio of MWCNTs;

[0034] Step 2. Add grinding balls, 90g of spherical atomized copper powder with a particle size of 120μm, and MWCNTs treated in step 1 (control the mass fraction of MWCNTs in MWCNTs / Cu composite powder to be 5%) into the horizontal high-energy stirring ball mill in turn , the material of the grinding balls in the horizontal high-energy stirring ball mill is bearing steel, the size is Ф3mm, and then the chamber is sealed and filled with argon 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com