Marking layer detimber auxiliary dismounting vehicle for building

A technology for building and dismantling vehicles, which is applied in construction, building maintenance, building construction, etc. It can solve problems such as waste of resources, potential safety hazards, and increased construction costs, so as to increase the secondary use rate, facilitate movement, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

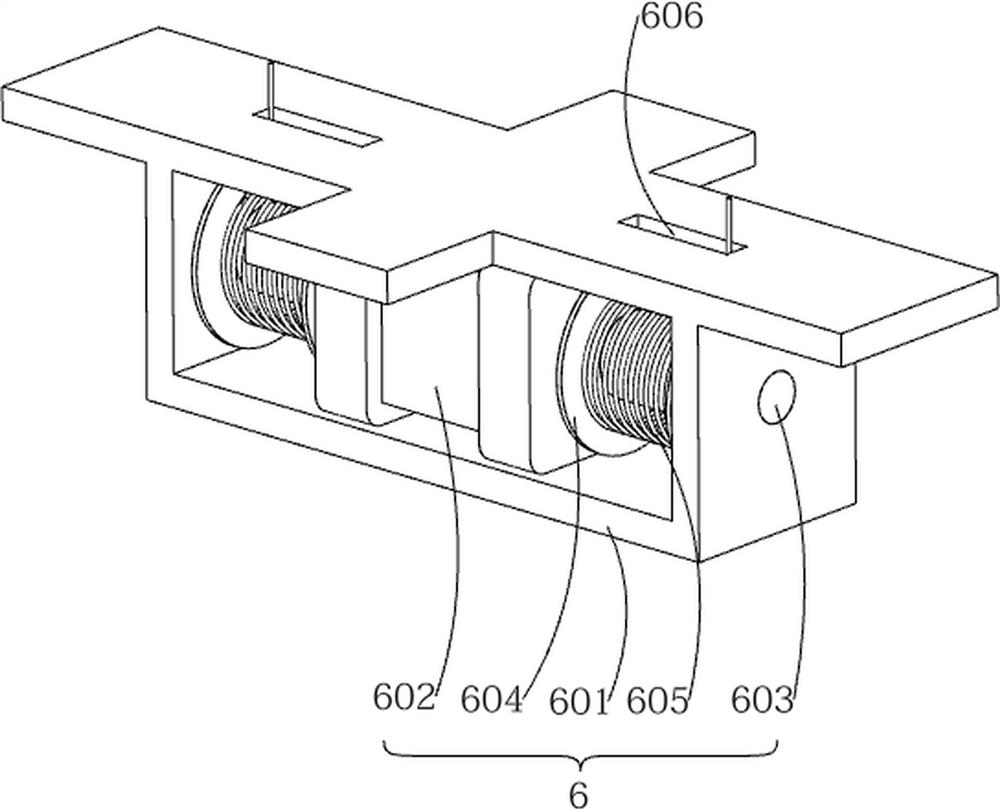

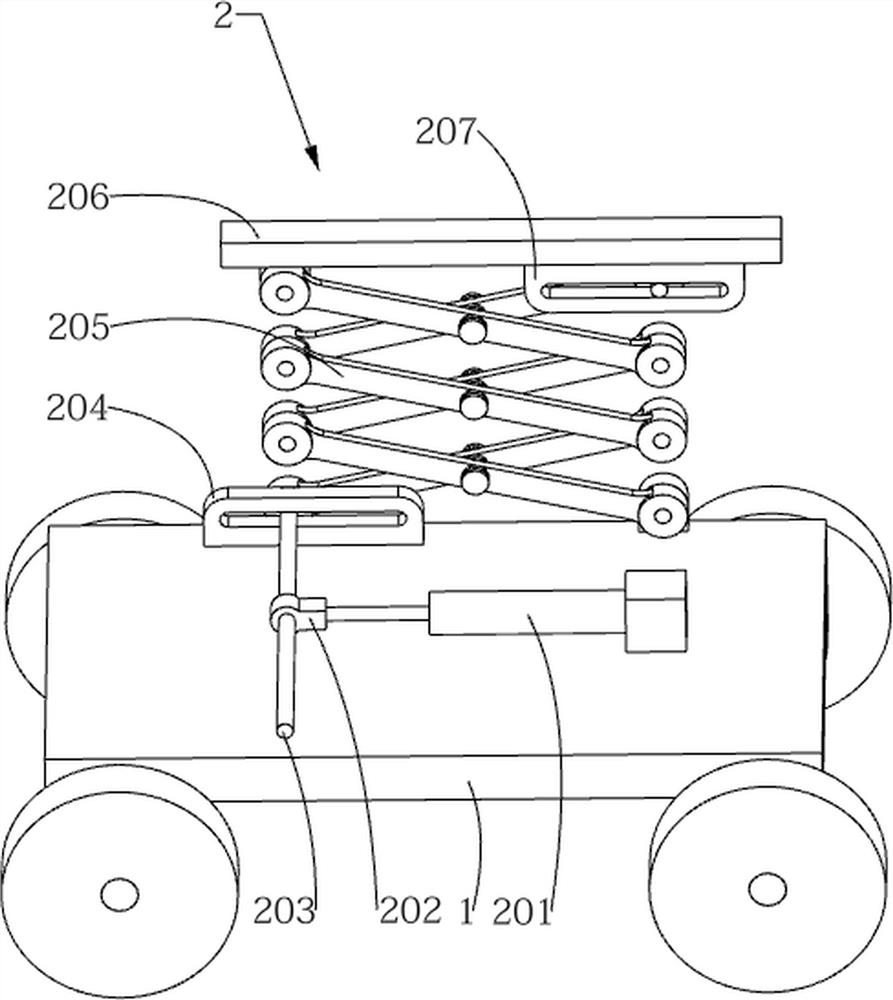

[0029] A kind of aided dismantling vehicle for standard layer stripping of wood, such as figure 1 As shown, it includes a mobile car board 1, a placement table 101, a scissor lifting device 2, a rotating machine 3, a flap 4, a connecting plate 5 and a standard layer dewood removal device 6~7, and the mobile car board 1 top is provided with There is a placing table 101 and a scissor lifting device 2. The top of the scissor lifting device 2 is fixedly connected with a rotating machine 3. The board 5 is provided with a standard layer dewood removal device 6~7, and the standard layer dewood removal device 6~7 is composed of a coiler 6, a sucker adjustment mechanism 7 and an adjustable sucker assembly 8, and the coiler 6 is fixedly connected to the On the connecting plate 5 , the end of the winding machine 6 away from the connecting plate 5 is symmetrically connected to the suction cup adjusting mechanism 7 , and the adjustable sucking cup assembly 8 is connected to the sucking cup...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 2-6As shown, the scissor lifting device 2 includes a first cylinder 201, a connecting head 202, a toggle lever 203, a first chute plate 204, a scissor frame 205, a supporting plate 206 and a second chute plate 207, and the mobile vehicle A first cylinder 201 is fixedly connected to one side of the top of the board 1, a connector 202 is fixedly connected to the expansion rod of the first cylinder 201, and a toggle rod 203 is fixedly sleeved in the connector 202, and a moving rod 203 is fixedly connected to both sides of the mobile vehicle board 1. For the first chute plate 204, the two ends of the toggle lever 203 are slidably connected with the first chute plate 204, and a scissor frame 205 is hinged on both sides of the mobile car plate 1, and the lower ends of the scissor frame 205 on both sides are connected to each other. Rotately connected with the toggle lever 203, the top of the scissor frame 205 is hinged with a support...

Embodiment 3

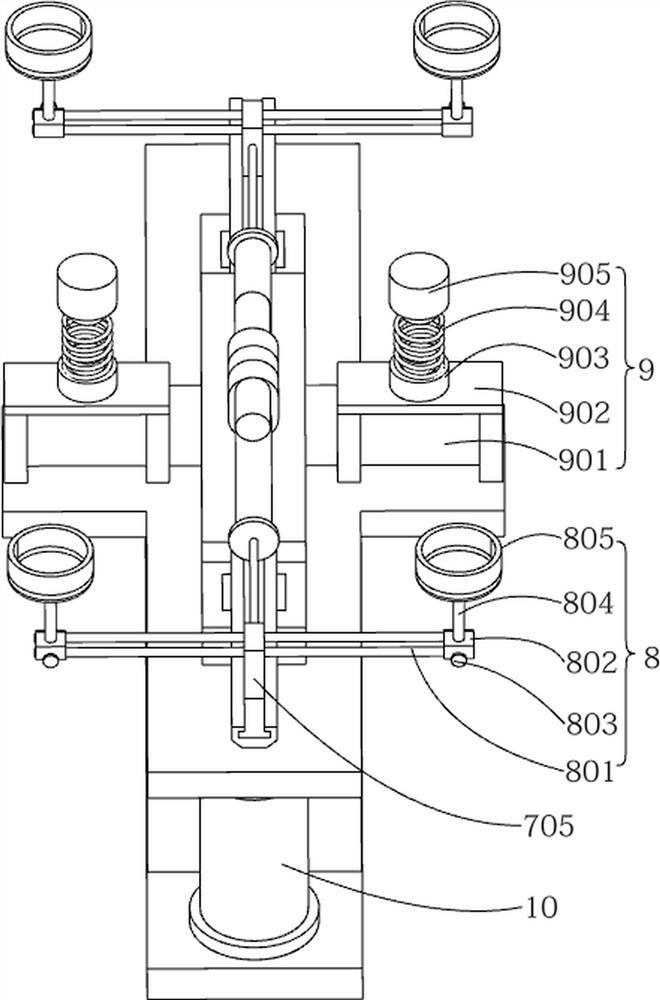

[0043] On the basis of Example 2, such as Figure 7 As shown, the vibration assembly 9 is also included. The vibration assembly 9 is fixedly connected to both sides of the top of the housing 601. The vibration assembly 9 is located on both sides of the suction cup adjustment mechanism 7. The vibration assembly 9 includes a vibration motor 901, a fixed plate 902, a connecting seat 903, The spring 904 and the vibration pad 905, the top of the housing 601 is fixedly connected with a vibration motor 901, the vibration motor 901 is fixedly connected with a fixed plate 902, the top of the fixed plate 902 is fixedly connected with a connecting seat 903, and the connecting seat 903 is fixedly connected with a spring 904, the spring The other end of 904 is fixedly connected with vibration pad 905 .

[0044] When the plank bonding on the standard layer is relatively strong, and the circular suction cup 805 is difficult to take the plank downward, start the vibrating motor 901, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com