Method of preparing semi-circular hole by casting

A semi-circular, hole core technology, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of difficult realization and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

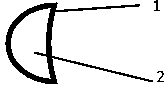

[0012] This embodiment is described by taking the casting of a semicircular through hole with a radius of 3 mm and a length of 30 mm as an example. Carry out molding according to the designed casting structure; according to the shape of the semicircular hole, apply the graphite coating evenly on the semicircular iron frame to obtain the semicircular hole core, which is consistent with the semicircular hole to be formed The hole size is the same, put the semicircular hole core into the pre-formed hole position in the cavity; pour the molten metal aluminum into the mold at a pouring temperature of 700°C, and obtain the casting after cooling and solidification; after taking out the casting Pull out the semicircular core to obtain a semicircular hole. Such as figure 2 shown.

[0013] The above-mentioned embodiments are helpful for illustrating the present invention, rather than limiting the present invention, and improvements to the present invention under the premise of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com