Overconstrained Parallel Mechanism with Equivalent Tricept Mechanism Motion

A mechanism movement and over-constraint technology, applied in the direction of manipulators, manufacturing tools, program control manipulators, etc., can solve the problem of reducing the number of joints, and achieve the effect of less joints, excellent motion characteristics, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] Example 1

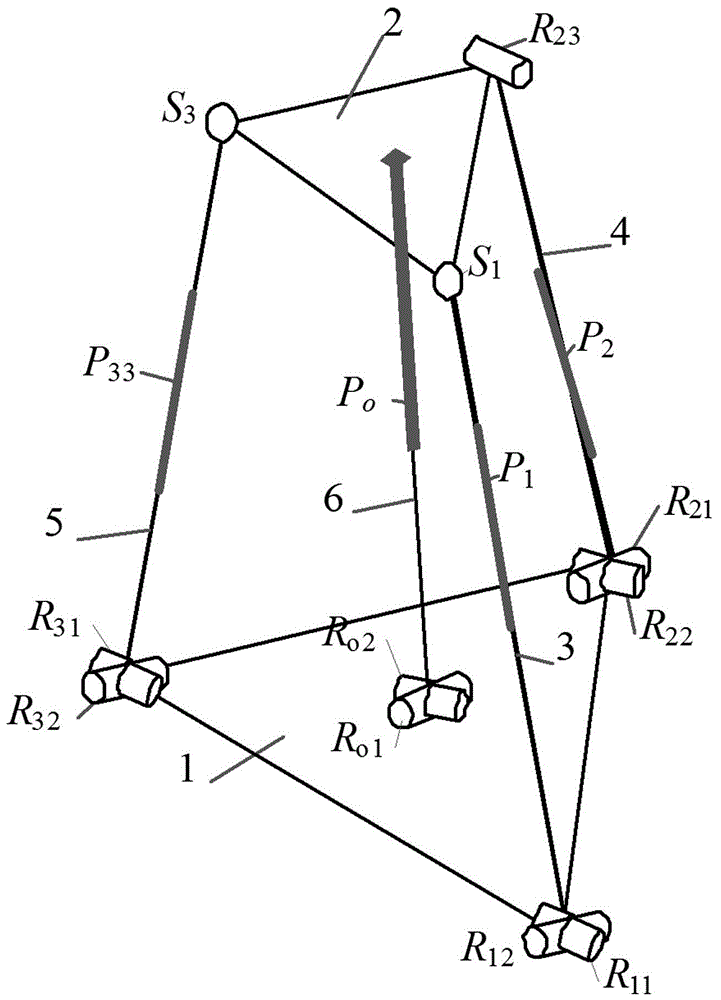

[0017] figure 1 This is the first embodiment disclosed in the present invention. The over-constrained parallel mechanism with equivalent Tricept mechanism motion of the present invention includes a fixed platform 1, a movable platform 2, three driving branches (3, 4, 5) connecting them, and an intermediate constraint branch 6. Among them, the fixed platform 1 and the movable platform 2 are both equilateral triangles. The two ends of the three driving branches (3, 4, 5) are respectively connected to the fixed platform 1 and the 3 vertices of the movable platform, and the middle restraining branch 6 connects the fixed platform 1 and The center of moving platform 2.

[0018] In the first drive branch 3, a universal hinge (R 11 , R 12 ), mobile pair (P 1 ) And ball pair (S 1 ), the outer rotating pair of universal hinge (R 11 ) Is ...

Embodiment 2

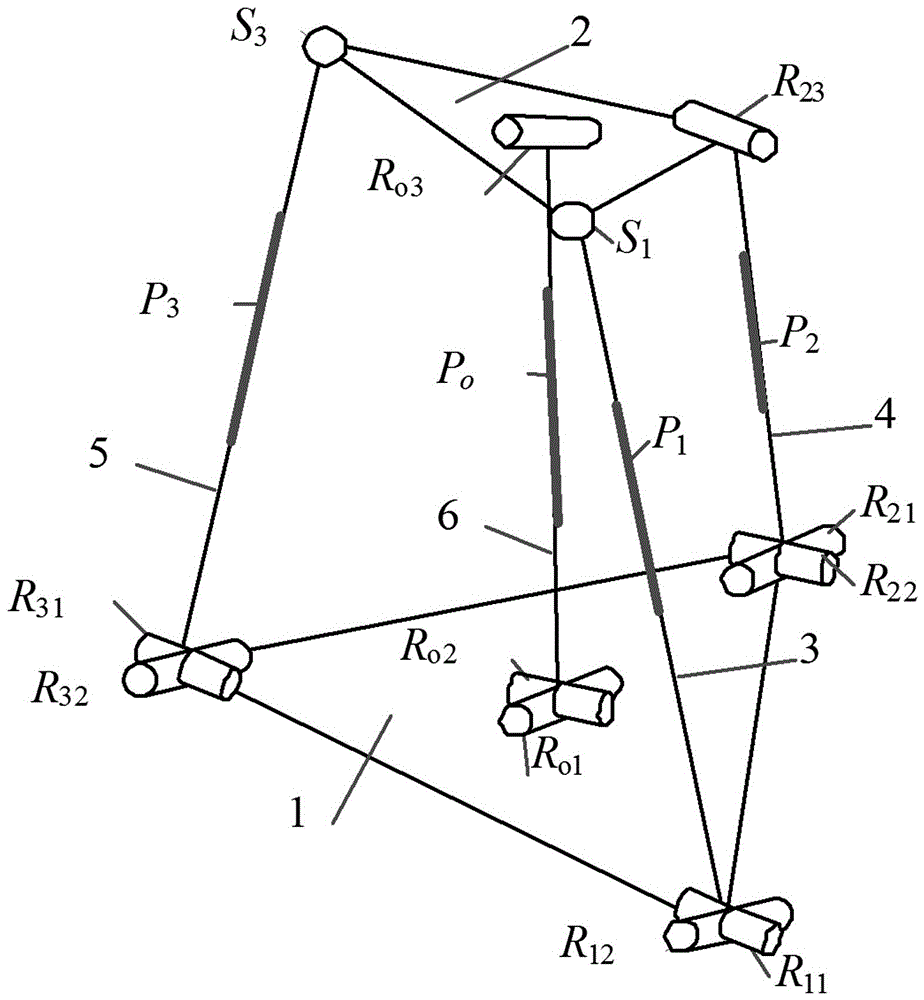

[0020] figure 2 This is the second embodiment disclosed in the present invention. figure 2 Among them, the middle constraint branch 6 is the UPR branch, and the constraint branch 6 is connected in series with universal hinges (R 01 , R 02 ), mobile pair (P 0 ) And rotating pair (R 03 ). Outer rotation pair of universal hinge (R 01 ) Is connected to the center of the fixed platform 1, and its axis points to the lower end of the second drive branch 4, and is connected to the second drive branch 4 universal hinge outer rotating pair (R 21 ) Collinear, universal hinge inner rotating pair (R 02 ) Is perpendicular to the rotation pair (R 03 ), and the moving pair (P 0 ) Vertical, rotating pair (R 03 ) Is connected to the moving platform 2, and its axis points to the upper end of the second driving branch 4. The other part of the connection mode is the same as in Example 1.

Embodiment 3

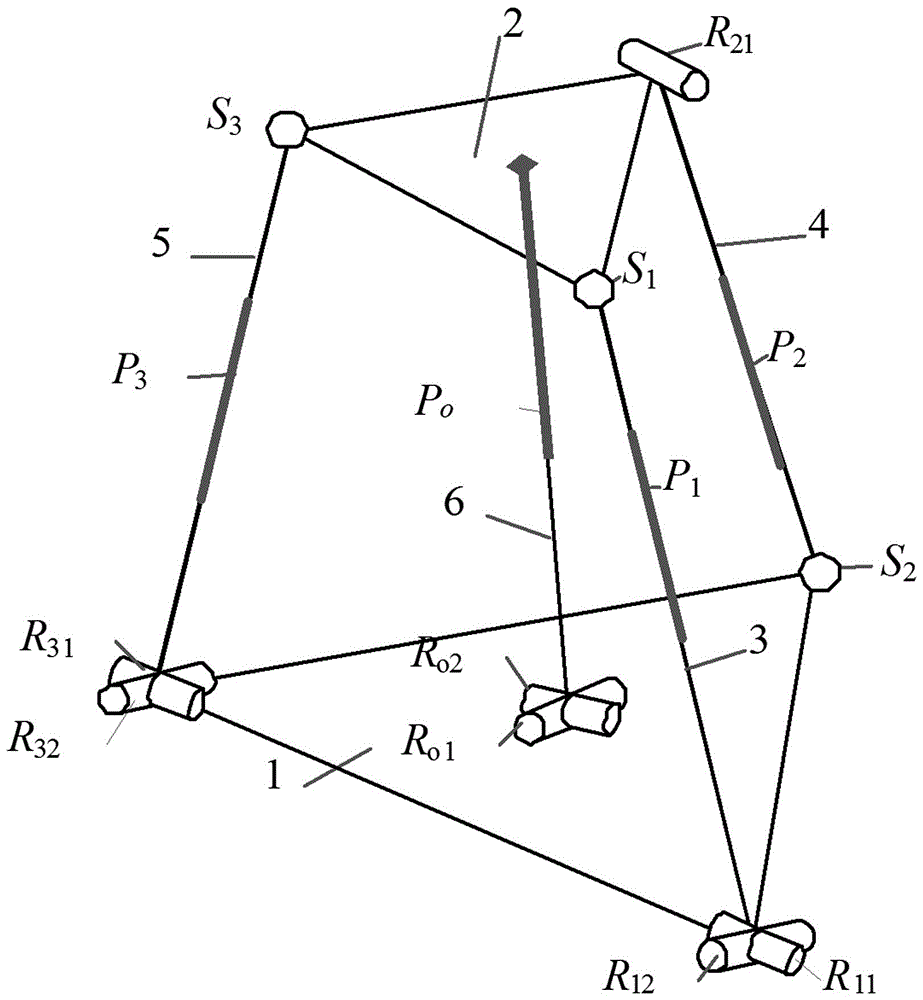

[0022] image 3 This is the third embodiment disclosed in the present invention. image 3 In the second driving branch 4 is the SPR branch, the second driving branch 4 is connected in series with ball pairs (S 2 ), mobile pair (P 2 ) And rotating pair (R 21 ). Among them, the ball pair (S 2 ) Is connected to the fixed platform 1, the rotating pair (R 21 ) Is connected to the moving platform 2, its axis is parallel to the opposite side of the moving platform 2, and is connected to the moving pair P 2 vertical. The other part of the connection mode is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com