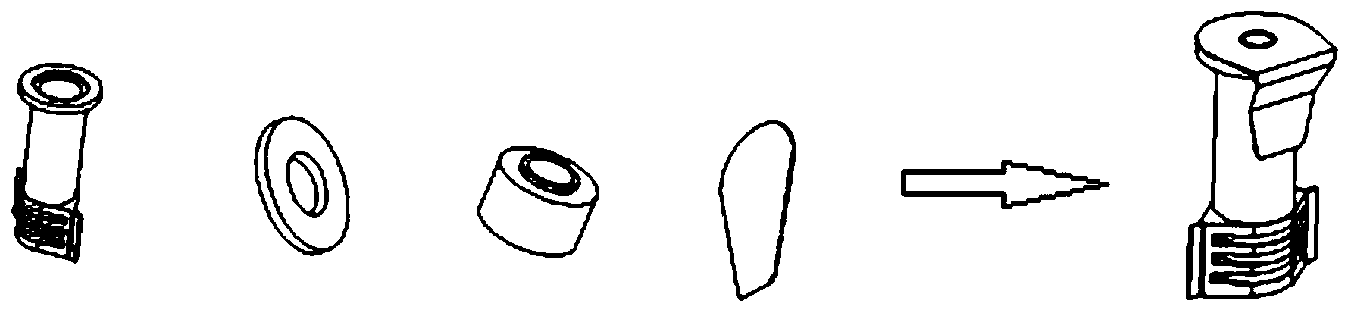

Method and equipment for linear batch assembly of medical drug package material

A pharmaceutical packaging material, linear technology, applied in metal processing and other directions, can solve the problems of high labor intensity, many intermediate turnover links, low production efficiency, etc., to achieve high production efficiency, reduce intermediate turnover links, and improve quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

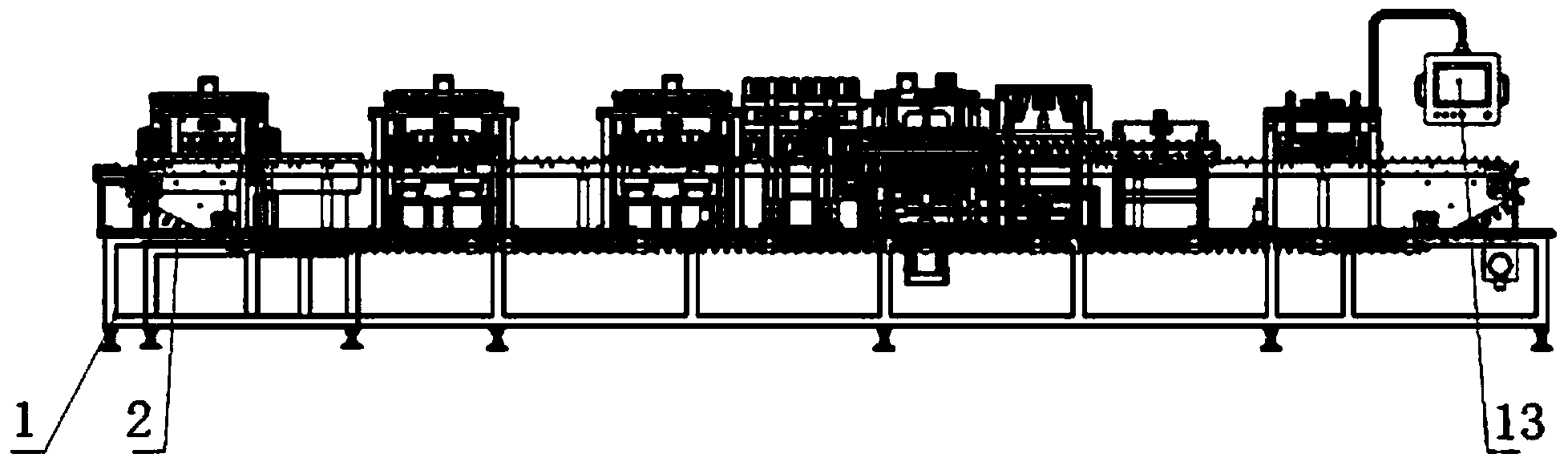

[0068] Such as Figure 1 to Figure 31 As shown, a linear batch-assembling equipment for medical drug packaging materials includes a frame body assembly 1, a main conveying chain assembly 2, a tube delivery assembly 3, a rubber stopper assembly 4, a tableting assembly 5, and a tracking tablet assembly 6. Ultrasonic welding assembly 7, punching film assembly 8, film feeding assembly 9, front welding film assembly 10, side welding film assembly 11, discharge assembly 12, electric control assembly 13. The tube feeding assembly 3, the rubber plug assembly 4, the sheet pressing assembly 5, the tracking sheet pressing assembly 6, the ultrasonic welding assembly 7, the punching film assembly 8, the film feeding assembly 9, the positive welding film assembly 10, and the side welding film assembly 11. The discharge assembly 12 and the electric control assembly 13 are installed on the frame body assembly 1 sequentially from front to back; the main conveying chain assembly 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com