A three-dimensional printing defective product repair system

A repair system and 3D printing technology, applied in the field of workpiece repair, can solve the problems of high repair cost, waste, increased destruction cost, etc., and achieve the effect of high precision and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

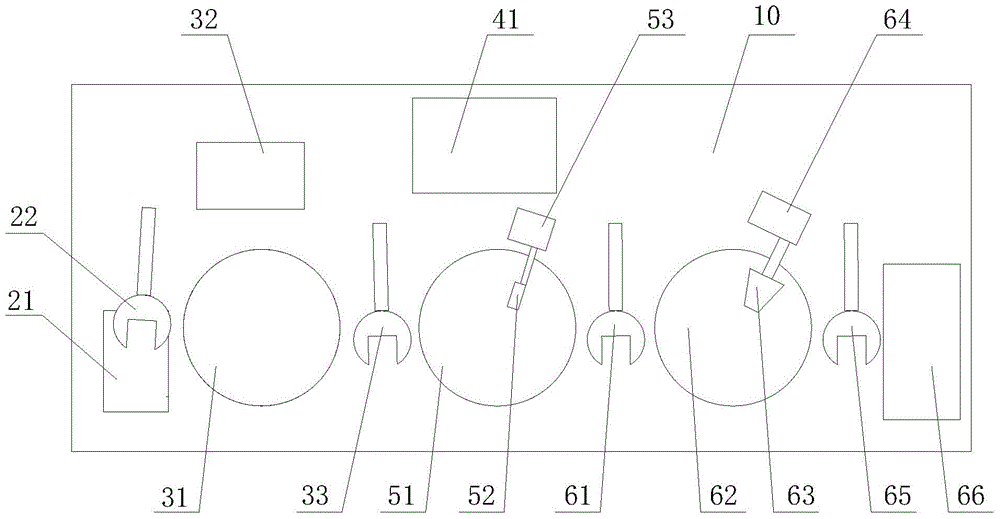

[0018] Such as figure 1 As shown, a three-dimensional printing defective repair system proposed by the present invention includes: a base 10, a loading module, an inspection module, a finished product blanking module, a defect removal module, a repair module and a control module.

[0019] The loading module includes: a first material bin 21 and a first clamping member 22 . The first clamping part 22 is installed on the base 10 and is used for sending the workpiece to be inspected in the first magazine 21 into the inspection module.

[0020] The inspection module includes: a first workbench 31 , a three-dimensional scanning device 32 and a second clamping member 33 . The first workbench 31 is installed on the base 10 and is used to carry workpieces to be inspected. The three-dimensional scanning device 32 is installed on the base 10 and is used to scan the workpiece to be inspected. The second clamping member 33 is installed on the base 10 and is used to clamp the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com