A Green Preparation Method of Lightweight and Low Thermal Conductivity γ-Y2Si2O7 Porous Ceramics

A technology of porous ceramics and low thermal conductivity, which is applied in the field of γ-Y2Si2O7 porous ceramic materials, can solve the problems of toxicity, unfavorable green industrial production, and few researches on porous ceramics, and achieves simple preparation methods, easy large-scale production, and wide variety of raw materials little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First weigh 50g of deionized water, add 1g of citric acid and Y 2 o 3 : SiO 2 100g of mixed powder with a molar ratio of 1:2, mixed, Y 2 o 3 and SiO 2 The particle size of the mixed powder is 1-2 μm, and then stirred for 3 hours to form a slurry;

[0027] Then the slurry is placed in a water bath at 45° C., 1.5 g of sodium lauryl sulfate is added, stirred rapidly (the speed of the mixer is 1700 rpm) and foamed for 20 minutes, then 3.5 g of gelatin and 3 g of glycerol are added, and stirred for 5 minutes Post-injection molding, forming a green body after demoulding;

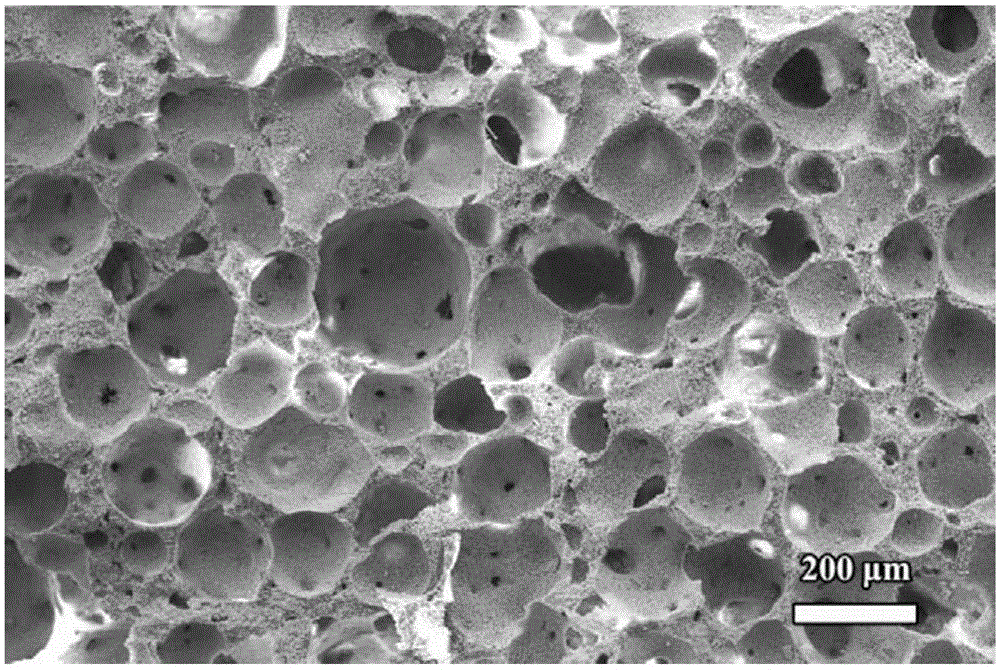

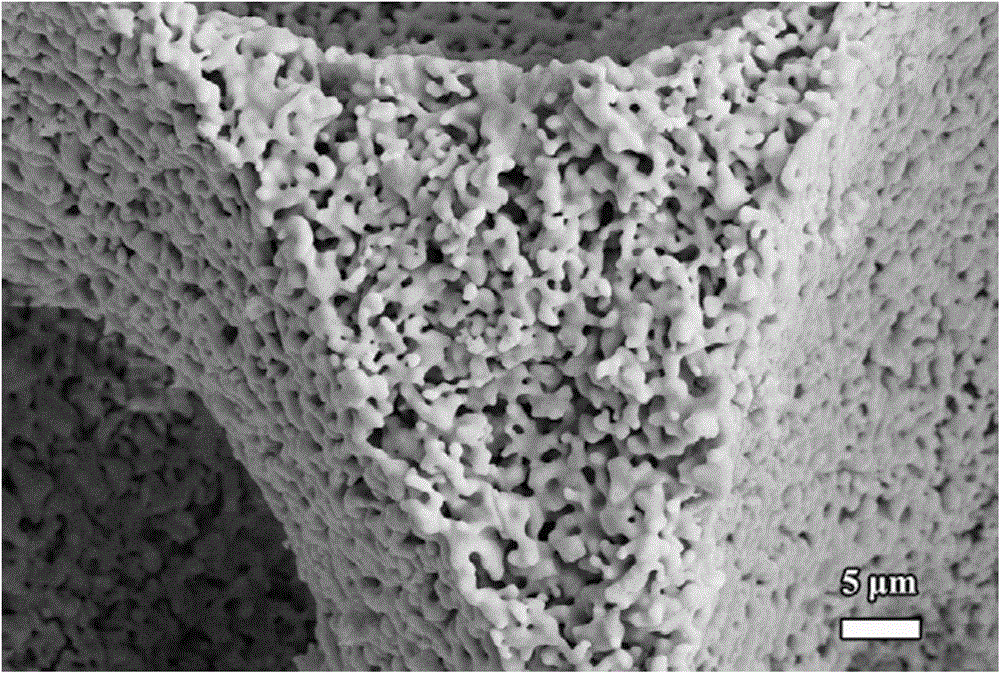

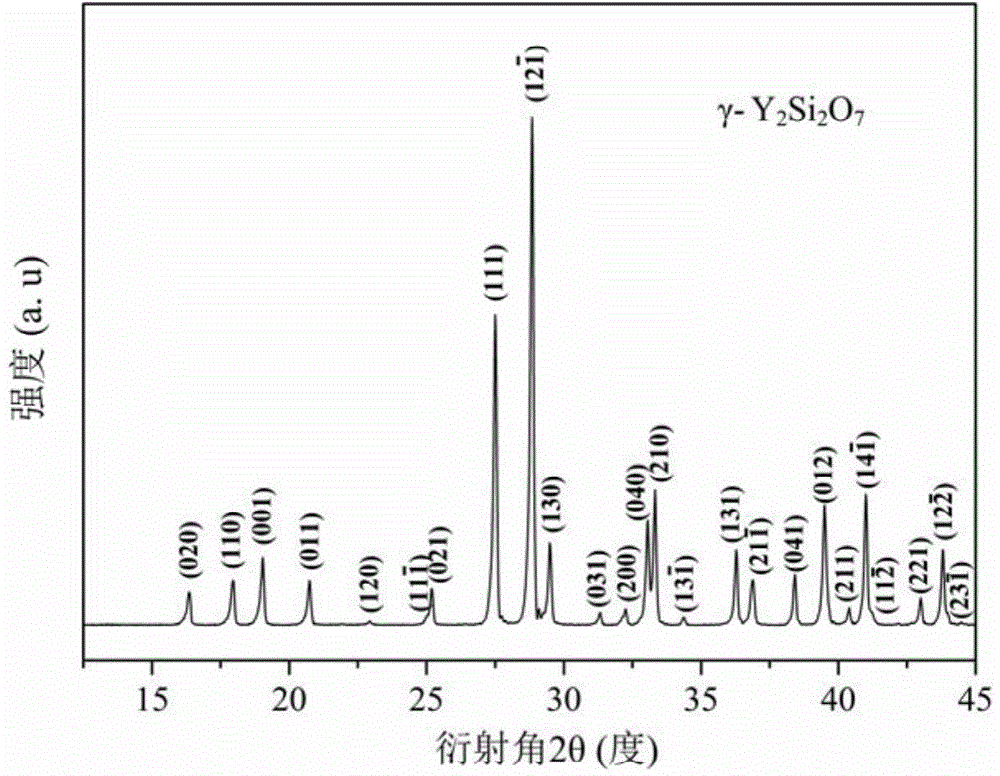

[0028] Dry the green body at room temperature for 20 hours, then dry it in an oven at 75°C for 25 hours, and finally perform high-temperature reaction sintering at 1525°C in the air. The heating rate of high-temperature reaction sintering is 5°C / min, and the holding time is 1.5 hours. Burn off organic compounds and synthesize γ-Y with light weight, high porosity and low thermal conductivity through gr...

Embodiment 2

[0030] First weigh 40g of deionized water, then add 0.5g of ammonium citrate and Y 2 o 3 : SiO 2 80g of mixed powder with a molar ratio of 1:2, mixed, Y 2 o 3 and SiO 2 The particle size of the mixed powder is 2 to 3 μm, and then stirred for 1.5 hours to form a slurry;

[0031] Then slurry is placed in the water bath of 40 ℃, adds sodium lauryl sulfate 0.6g, stirs rapidly (mixer rotating speed is 1500rpm) and foams for 10 minutes, then adds gelatin 2.5g and polyethylene glycol 2g, stirs for 10 minutes Minutes later injection molding, forming green body after demoulding;

[0032] Dry the green body at room temperature for 30 hours, then dry it in an oven at 65°C for 30 hours, and finally perform high-temperature reaction sintering at 1500°C in the air. The heating rate of high-temperature reaction sintering is 7°C / min, and the holding time is 2 hours. Burn out organic compounds, and prepare γ-Y with light weight, high porosity and low thermal conductivity through green pr...

Embodiment 3

[0034] First weigh 60g of deionized water, then add 1.5g of ammonium citrate and Y 2 o 3 : SiO 2 120g of mixed powder with a molar ratio of 1:2, mixed, Y 2 o 3 and SiO 2 The particle size of the mixed powder is 0.5-1.5 μm, and then stirred for 2 hours to form a slurry;

[0035] Then the slurry is placed in a water bath at 48° C., 2 g of sodium dodecylsulfonate is added, stirred rapidly (the speed of the mixer is 2000 rpm) and foamed for 25 minutes, then 4 g of gelatin and 5 g of polyethylene glycol are added, and stirred for 15 minutes Post-injection molding, forming a green body after demoulding;

[0036] Dry the green body at room temperature for 25 hours, then dry it in an oven at 85°C for 20 hours, and finally perform high-temperature reaction sintering at 1550°C in the air. The heating rate of high-temperature reaction sintering is 2°C / min, and the holding time is 1 hour. Burn out organic compounds, and prepare γ-Y with light weight, high porosity and low thermal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com