An anti-pilling, ultra-soft cotton wool cloth with peach skin feel and its production method

A production method and technology of cotton wool cloth, applied in the directions of singeing, fabric elongation, weaving, etc., can solve the problems of poor softness, easy to fluff, poor hand feeling, etc., and achieve good effect, short and dense fabric fluff, and dense fabric fluff. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Adopt following steps to make supersoft cotton felt cloth of the present invention:

[0036] (1) 100% long-staple cotton is used as raw material, treated with an aqueous cellulase solution with a pH value of 4-6, then deactivated in hot water at 50-60°C, and then soaked in a solution containing glycidyl ether, poly Cross-linking treatment in any one or more mixtures of glycidyl ether or glycidyl acrylate;

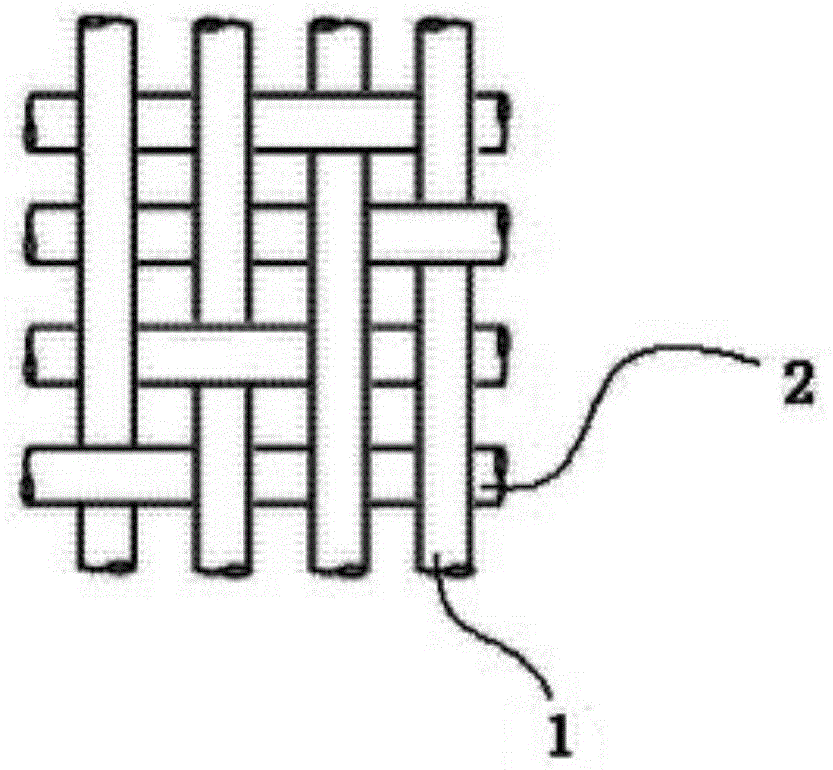

[0037] (2) Machine weaving;

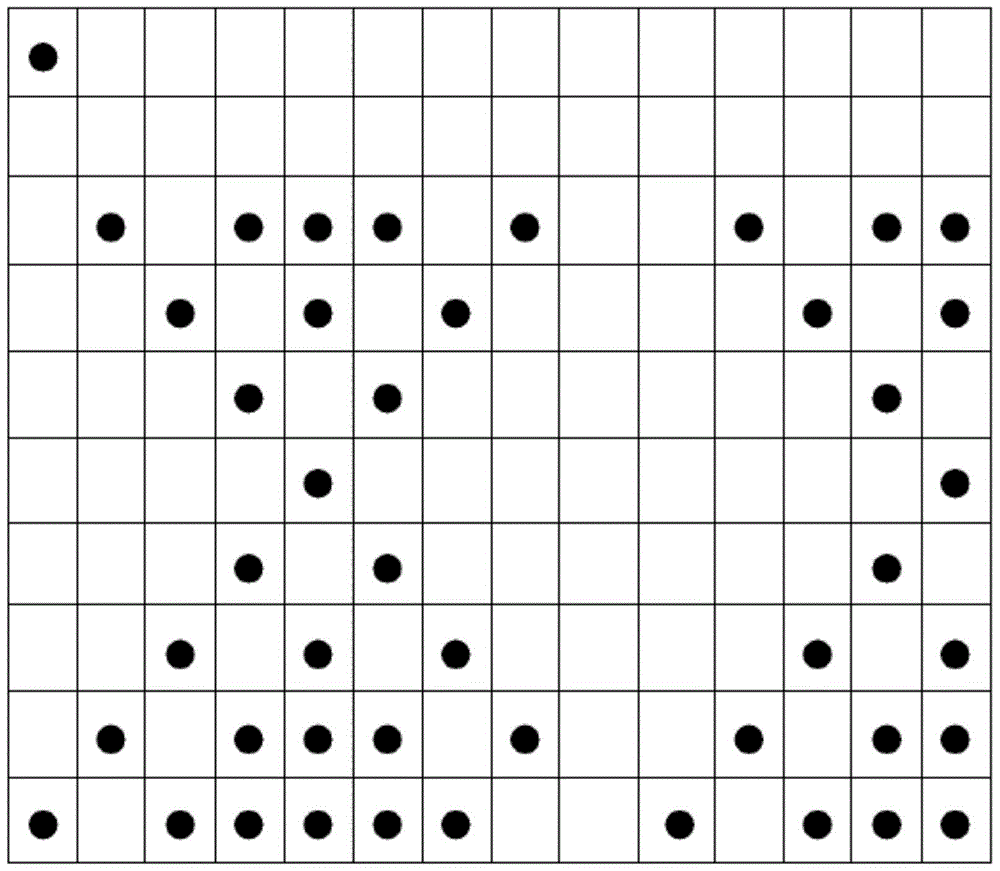

[0038] (3) Carry out sanding processing to the woven cotton wool cloth layer, and technology is to adopt imported carbon sanding machine, sanding 2 times, speed of a motor vehicle 8m / min, tension force 30kg, the rotating speed of bristle stick 70%;

[0039] (4) Carry out gas open-width singeing to the cotton wool cloth that has passed through grinding, and perform polishing, biological deoxygenation and dyeing with multi-component biological enzymes;

[0040] (5) After finishing, the process is:

[0041] SANTEX stenter drying: tempera...

Embodiment 2

[0051] Adopt following steps to make supersoft cotton felt cloth of the present invention:

[0052] (1) 100% long-staple cotton is used as raw material, treated with an aqueous cellulase solution with a pH value of 4-6, then deactivated in hot water at 50-60°C, and then soaked in a solution containing glycidyl ether, poly Cross-linking treatment in any one or more mixtures of glycidyl ether or glycidyl acrylate;

[0053] (2) Machine weaving;

[0054] (3) Carry out sanding processing to the woven cotton wool cloth layer, and technology is to adopt imported carbon sanding machine, sanding 3 times, speed of a motor vehicle 15m / min, tension force 50kg, the rotating speed of bristle stick 85%;

[0055] (4) Carry out gas open-width singeing to the cotton wool cloth that has passed through grinding, and perform polishing, biological deoxygenation and dyeing with multi-component biological enzymes;

[0056] (5) After finishing, the process is:

[0057] SANTEX tenter drying: tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com