High-speed railway bridge wind blocking structure

A technology for high-speed railways and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of wind-shielding structure height, opening ratio, wind-shielding effect columns and connection safety that cannot meet the operation requirements of high-speed railways, and achieve Good durability, strong applicability, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in combination with specific embodiments.

[0044] The present invention proposes a brand-new bridge wind-shielding structure. Under the premise of satisfying the safety of the bridge structure and the wind-shielding structure, by setting the wind-shielding structure to change the crosswind effect on the car body, the safety of train operation is improved. The critical wind speed increases the stability of train operation and reduces operational failures, thereby providing a favorable guarantee for trains passing safely on bridges in windy areas.

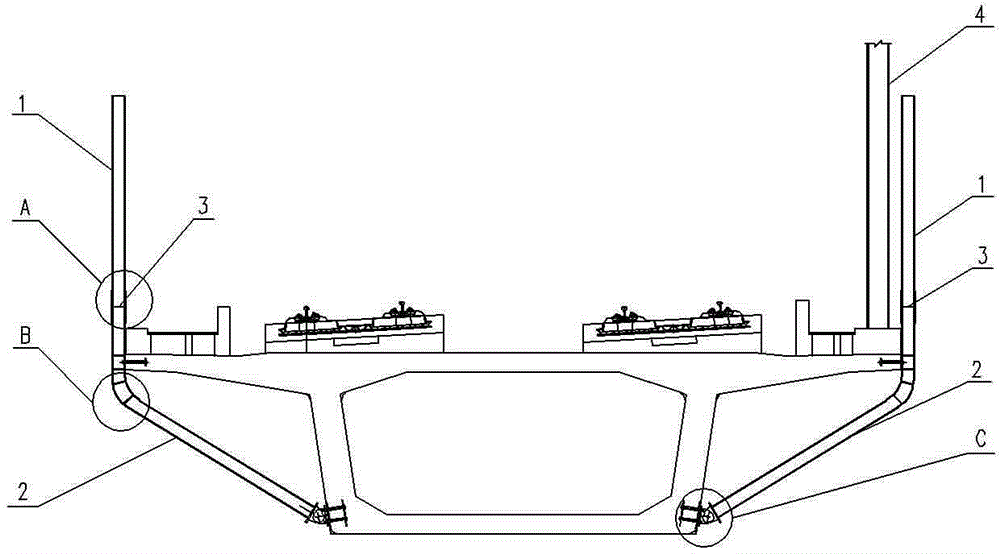

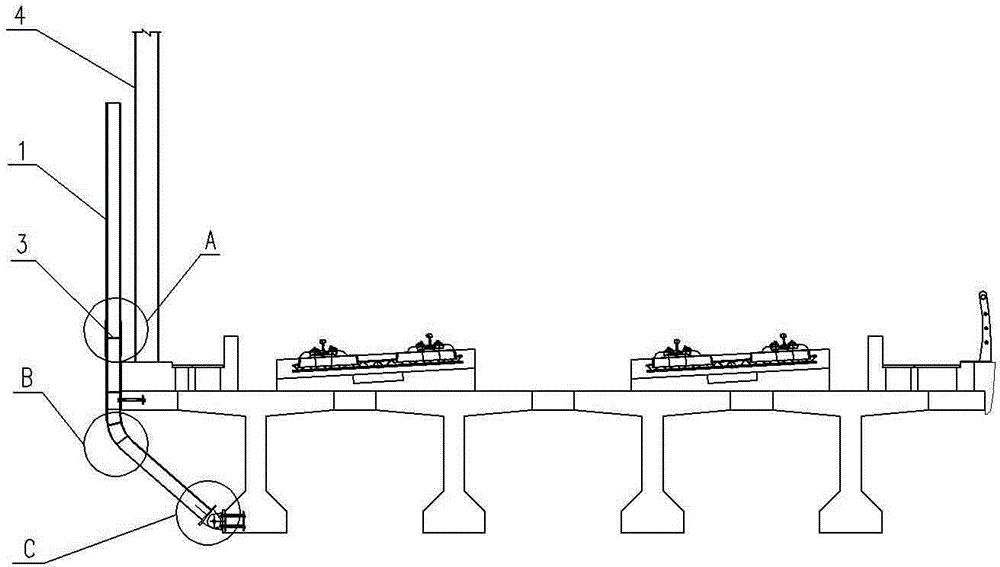

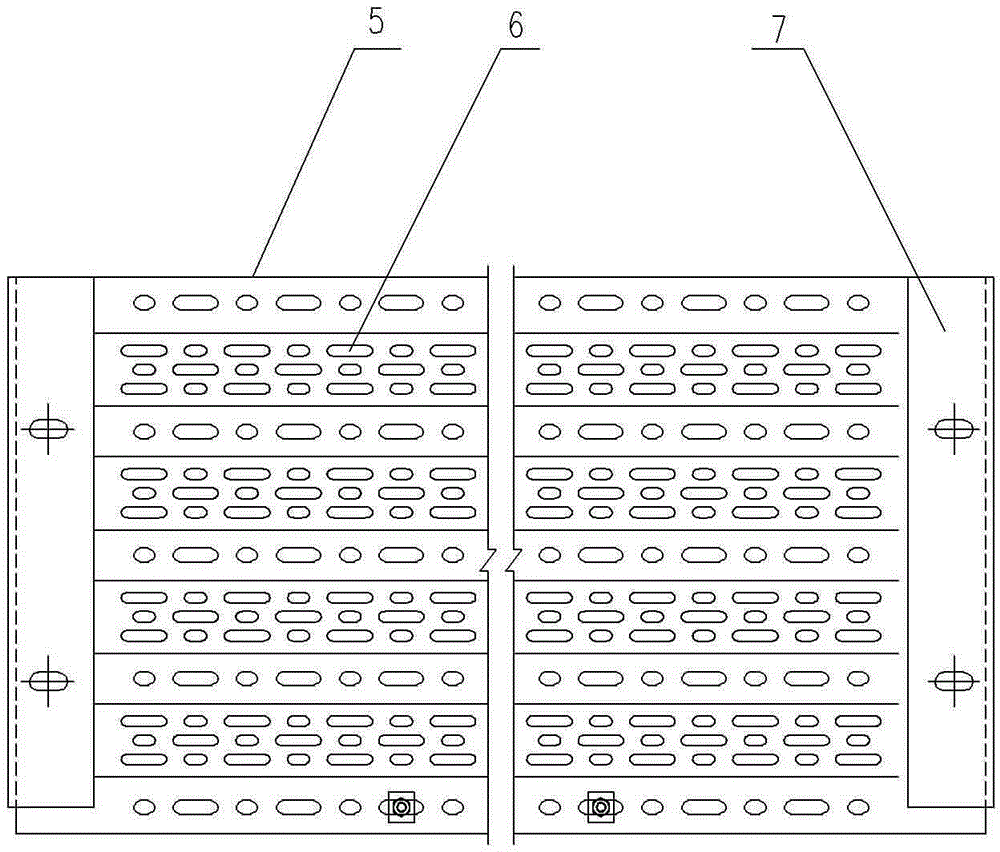

[0045] The involved windshield structure of a high-speed railway bridge is suitable for bridge structures of box girders and composite T girders, installed on the windward side of the bridge girder, and includes a column 1, a bent column 2 and a windshield 5.

[0046] The column 1 and the bent column 2 are both H-shaped steel (the cross-section is divided into H250×250×9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com