Combined steel structure building template

A technology for building formwork and steel structure, applied in the direction of building, building structure, formwork/formwork components, etc., can solve the problems of time-consuming construction and dismantling, less repeated use, waste of wood resources, etc., and meet the technical requirements of construction Low, simple to use, easy to build effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Construction of pillars

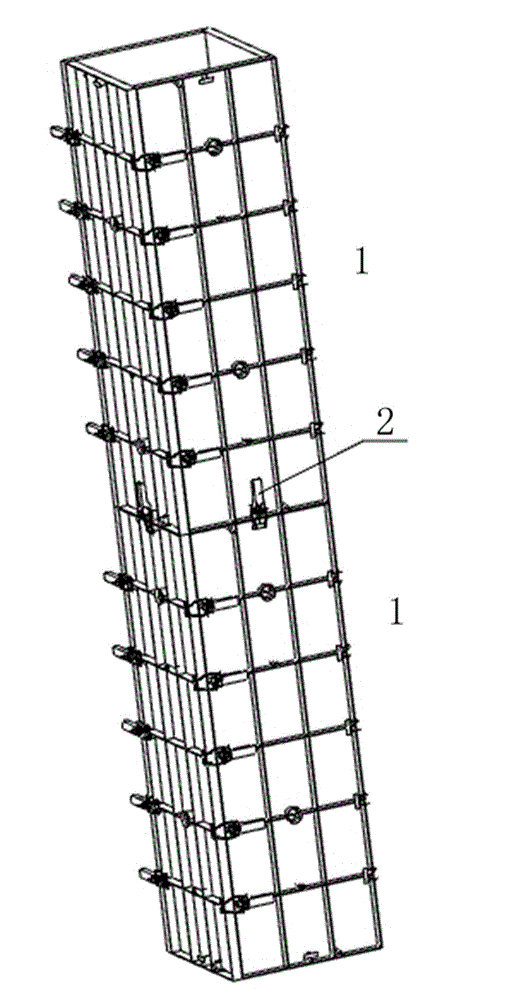

[0033] First determine the size of the column, choose the appropriate formwork to use with it, so that it can reach the required size. The most important thing in the construction of the column is the construction of the external angle. The main feature is that after the cooperation between formwork 1 and formwork 1 forms a 90-degree angle, each formwork can be connected and fixed by tower buckle 2 (such as figure 1 shown).

Embodiment 2

[0034] Example 2: Construction of Zenith

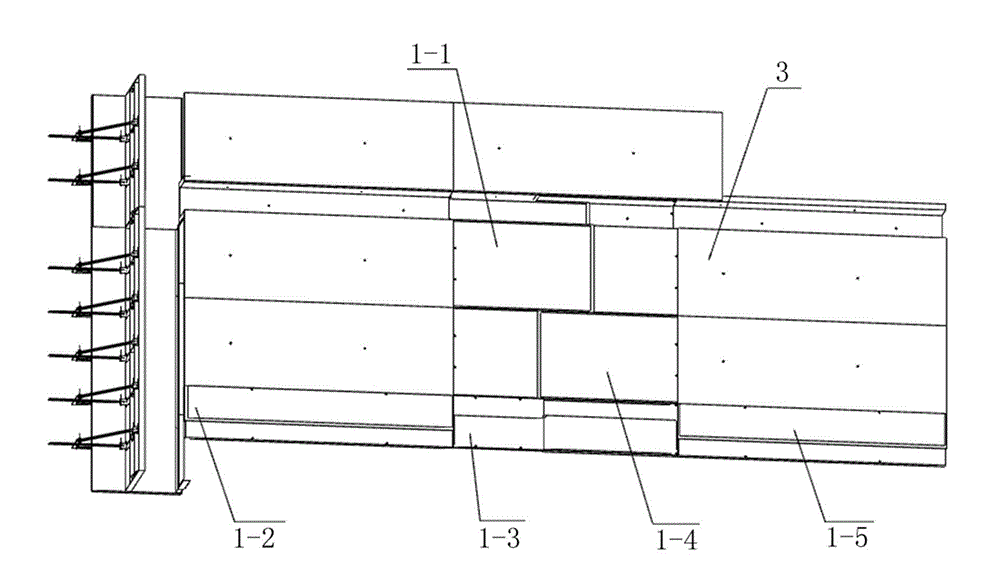

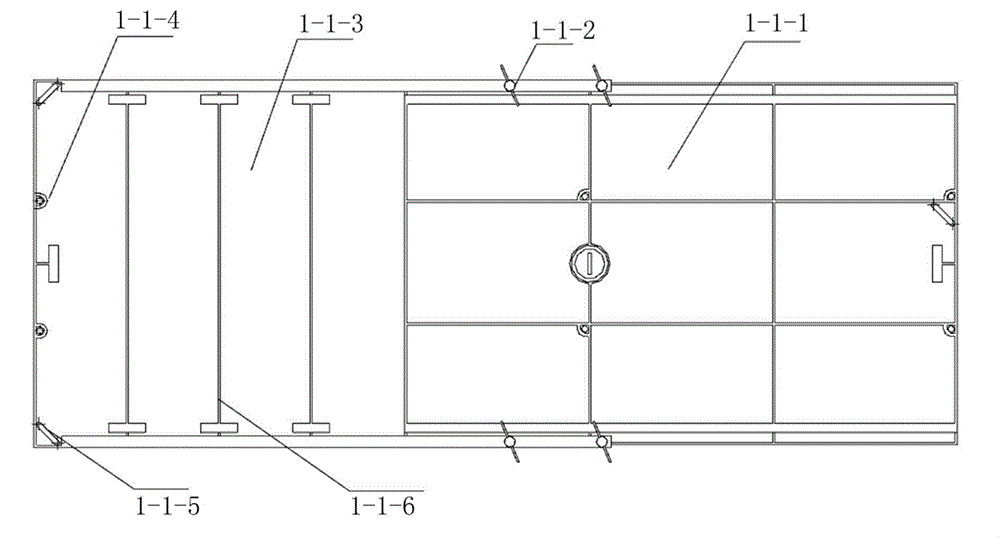

[0035] Determine the size of the zenith area, select the appropriate template to match to achieve the use size, if you want to have any size, you need to scale the template 1-5 horizontally, zoom 1-4 vertically, and scale the template 1-2 horizontally to the left and right. Side-by-side vertical scaling template 1-1, surrounding scaling template 1-3 and fixed-size template 3 are used together (such as figure 2 ), the horizontal zoom template 1-5, the vertical zoom template 1-4, the left and right horizontal zoom template 1-2, the left and right vertical zoom template 1-1, and the surrounding zoom template 1-3 are respectively composed of the fixed plate 1-1-1 and The sliding plate 1-1-3 is formed by the screw 1-1-2 and its movable connection, which can be adjusted according to the required size, and then tighten the screw 1-1-2 to fix it (such as image 3 ), the vertical scaling formwork 1-4, the left and right vertical scaling form...

Embodiment 3

[0036] Embodiment 3: Coordinated construction of the beam and the zenith

[0037] First determine the size of the beam, select the appropriate formwork to match to reach the use size, and then rely on the upper formwork 1 of the zenith formwork to connect and fix it with the curved tower buckle 6, which is the construction of the inner corner part (such as Figure 8 ), the lower formwork is lifted by the fixed size formwork 3 and then connected with the tower buckle 2 like a pillar, that is, the construction of the male corner part (such as Figure 9 ), the construction, determination and fixation of the template at the edge of the zenith can be realized by adjusting the angle and length of the stabilizing rod 7 (such as Figure 10 ), the lower end of the stabilizing rod 7 also works after being clamped with the template 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com