Screw protection cap of sleeve

A technology of protecting the wire cap and protecting the wire, which is applied to the casing, drilling pipe, packaging, etc., can solve the problems such as the difficulty of removing the wire protecting cap from the casing, the inability to disassemble the wire protecting cap during the placing time, and the operator's fall. , to achieve the effect of simple structure, reduce the difficulty of disassembly, and increase the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

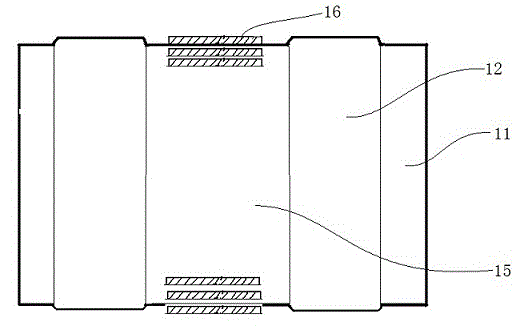

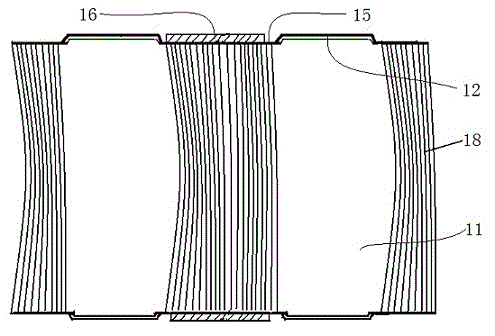

[0012] Such as figure 1 , figure 2 As shown, the present invention is a casing wire protection cap, which includes a wire protection body 11, an internal thread 18 arranged inside the wire protection body 11 and threadedly connected with the casing, and increasing the inner diameter of the wire protection body 11 Or the anti-friction resistance band 12 formed by removing partial threads, the anti-slip band 15 arranged adjacent to the anti-friction resistance band 12 , and the horizontal bar 16 arranged around the anti-slip band 15 along the axial direction of the wire guard body 11 . The casing wire protection cap adds a friction-reducing resistance band 12, which increases the diameter of the position without the anti-skid belt 15, thereby reducing the contact position between the casing wire protection cap and the casing, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com