Fender storage tooling

A fender and tooling technology, applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems of boards occupying space, occupying fender storage space, and low utilization rate of fender storage space, so as to achieve convenient drying, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

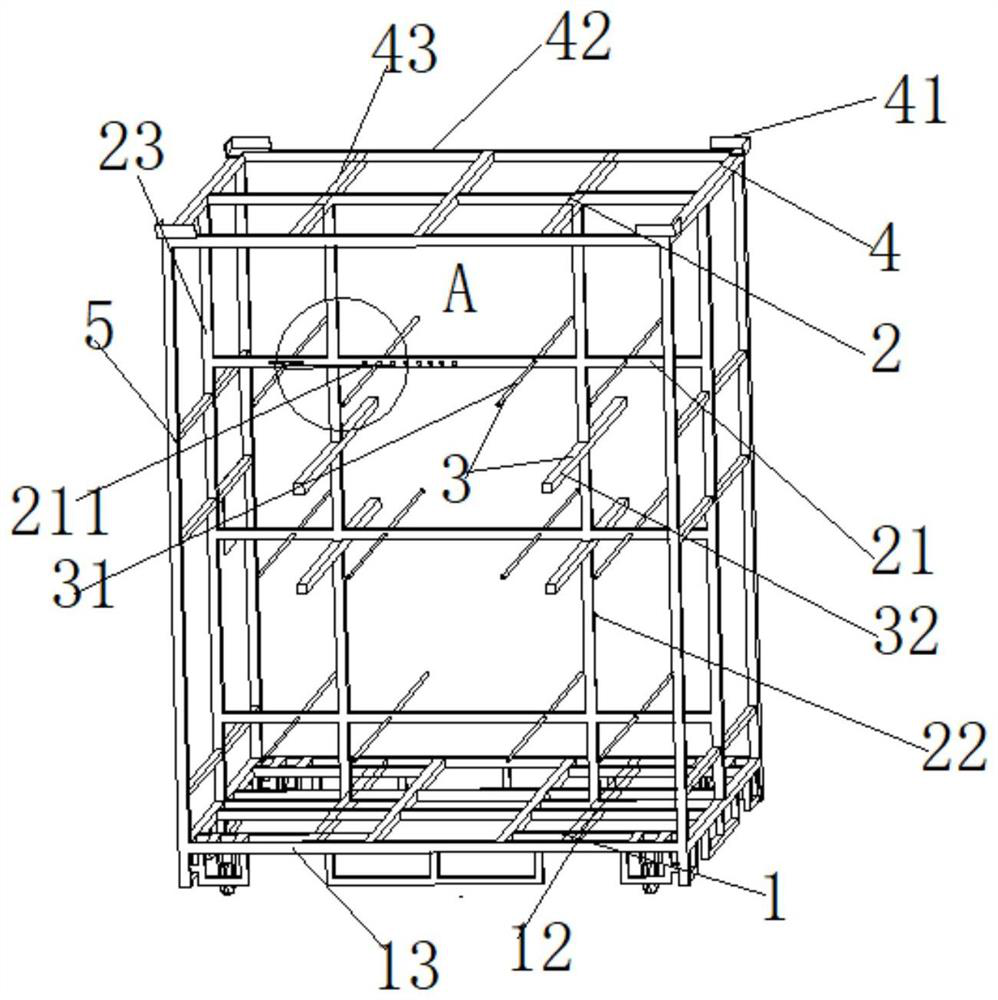

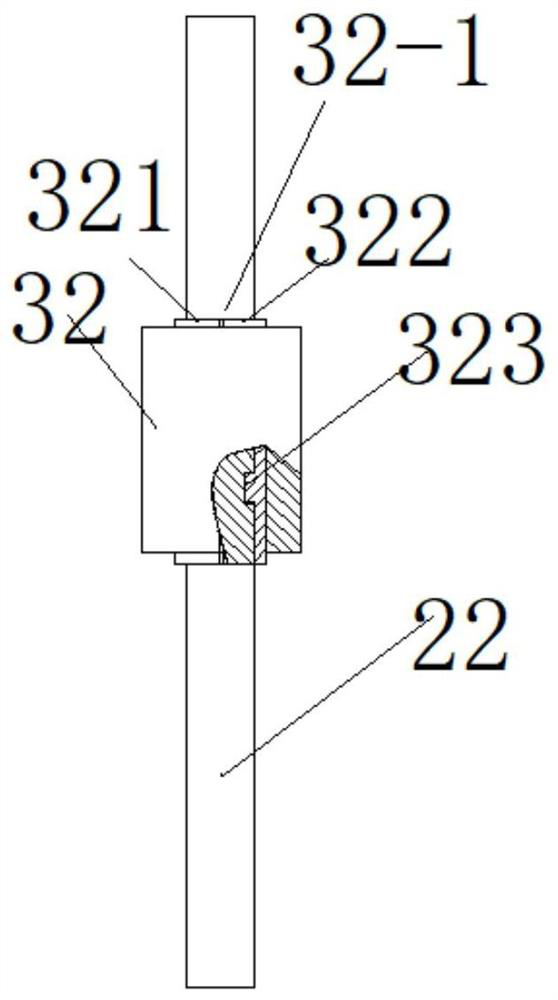

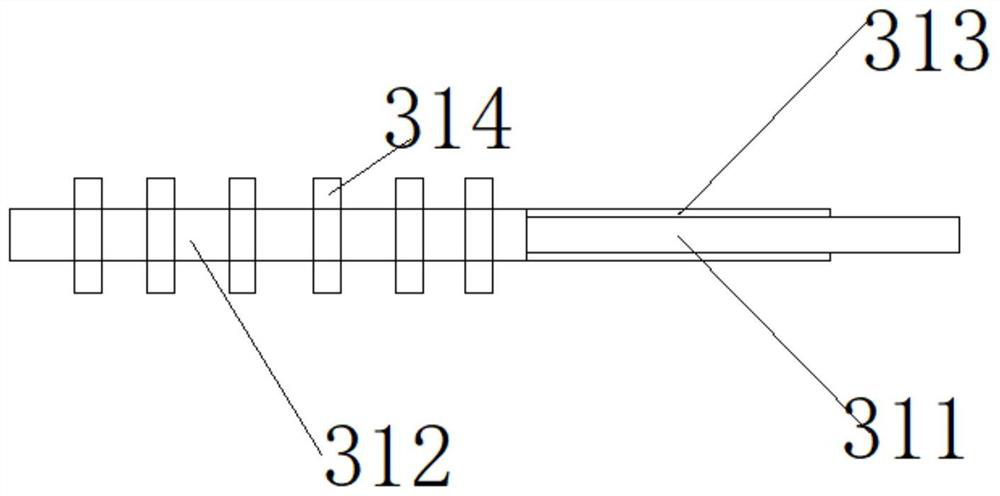

[0029] A fender storage tool, including a support frame, the support frame includes a bottom frame 1, a support frame 2 is provided on the bottom frame 1; a plurality of fender mounts are provided on the support frame 2 The hitch assembly 3, each of the hitch assemblies 3 includes a base frame 32 arranged on the support frame 2 and a hitch rod 31 arranged on the support frame 2 to cooperate with the corresponding base frame 32; each of the hanger assemblies The connecting assembly 3 is provided with at least two articulated rods 31, and the articulated rods 31 are located above the corresponding base frame 32; The cooperation of the fender can reduce the contact position between the fender and the tooling, especially after the fender is painted, it can reduce the damage of the tooling to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com