printer

A technology of printers and printing media, applied in typewriters, printing devices, printing, etc., can solve problems such as paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is related to Japanese Patent Application (Japanese Patent Application No. 2014-165847 ) filed on August 18, 2014, and the content of this application is incorporated in this specification as a reference.

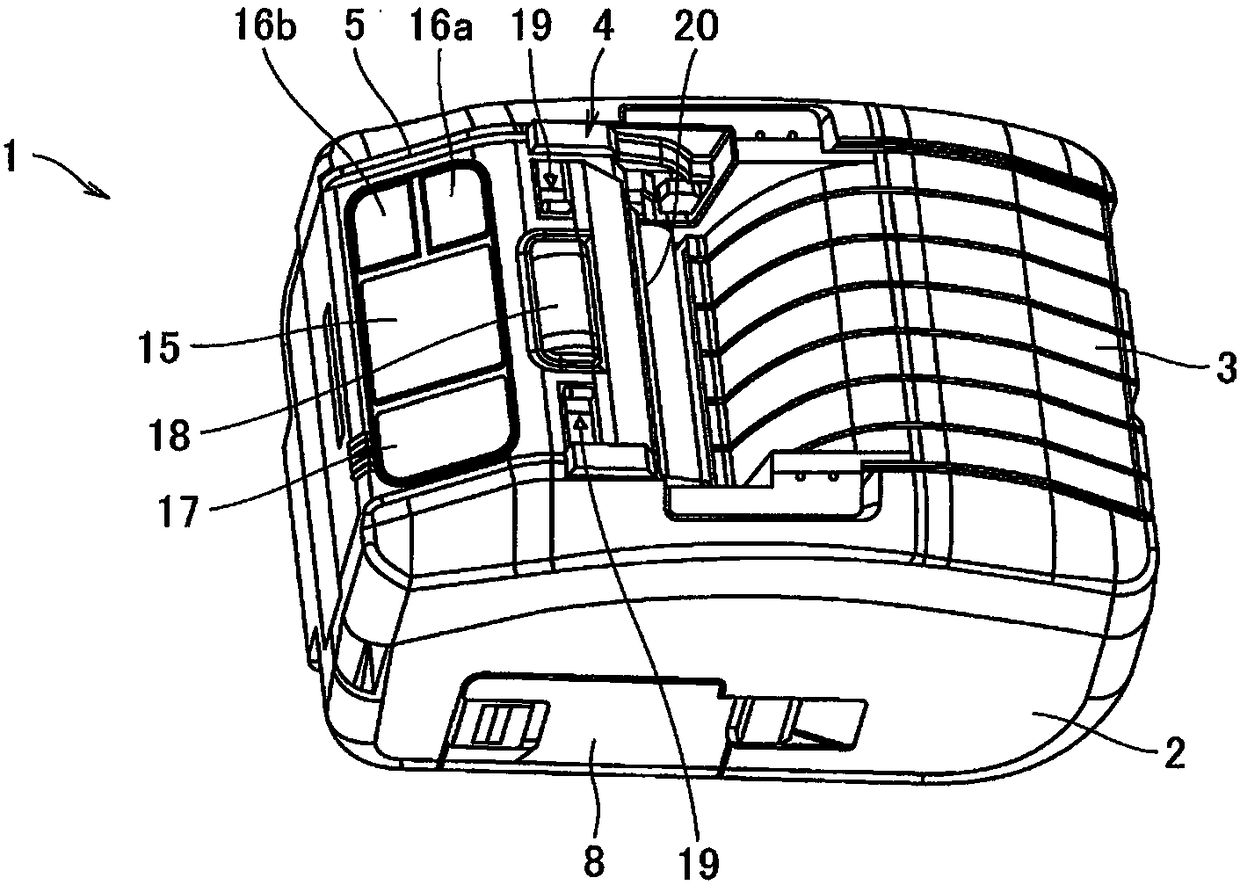

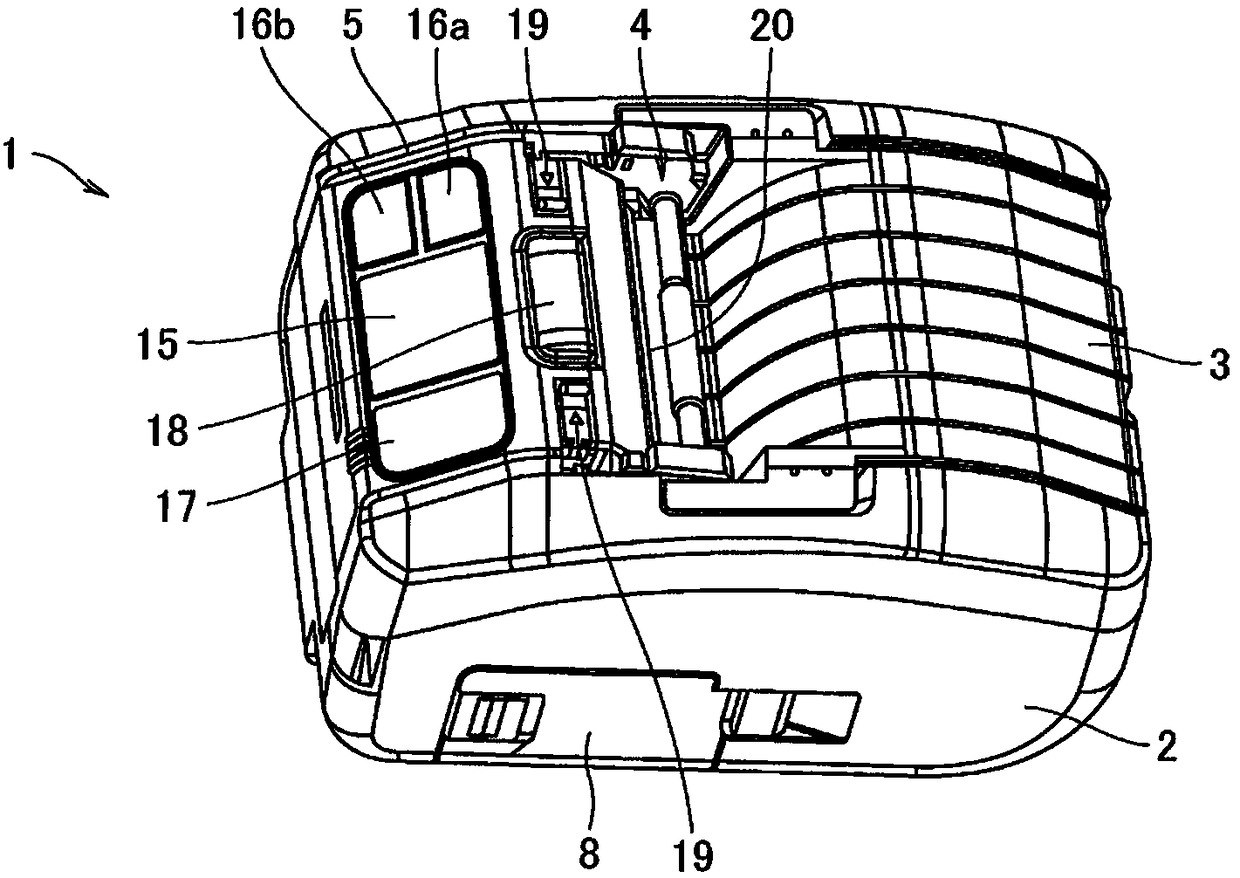

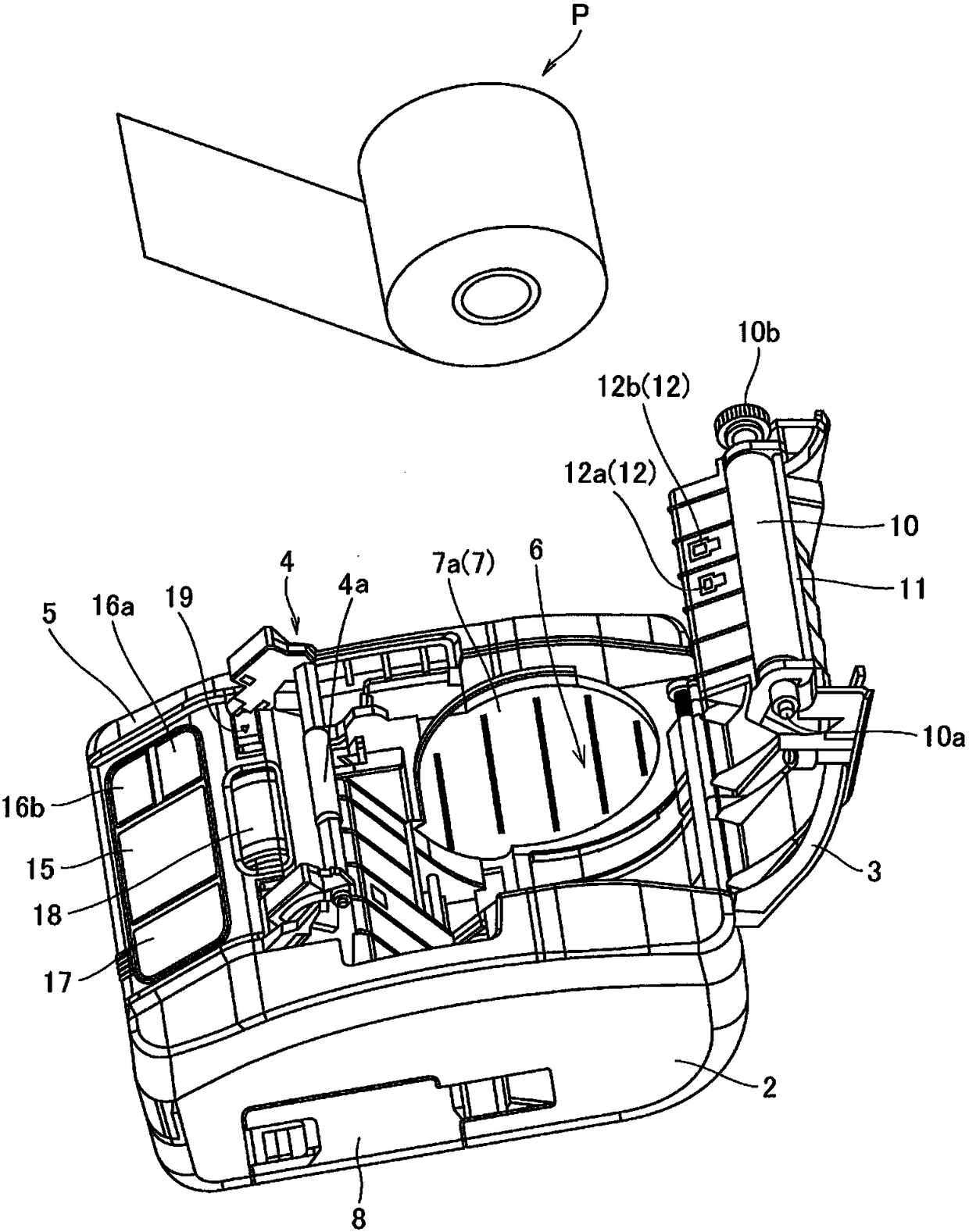

[0044] Hereinafter, an embodiment as an example of the present invention will be described in detail based on the drawings. In addition, in the drawings for explaining the embodiments, in principle, the same reference numerals are attached to the same components, and repeated description thereof will be omitted. The terms used in the embodiment will be briefly described as follows. Paper feeding refers to the action of conveying for printing on the label continuum (printing medium), and the paper feeding direction (printing conveying direction) refers to the direction of conveying for printing on the label continuum, specifically The direction in which the continuous label is conveyed from the paper supply unit to the thermal head. Reverse fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com