Marine Membrane Wall Oil Boiler

A technology of oil-fired boilers and membrane walls, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of increasing boiler use costs, frequent maintenance, and easy to be damaged by freezing, so as to reduce boiler energy consumption , Reduce maintenance costs, and improve startup speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

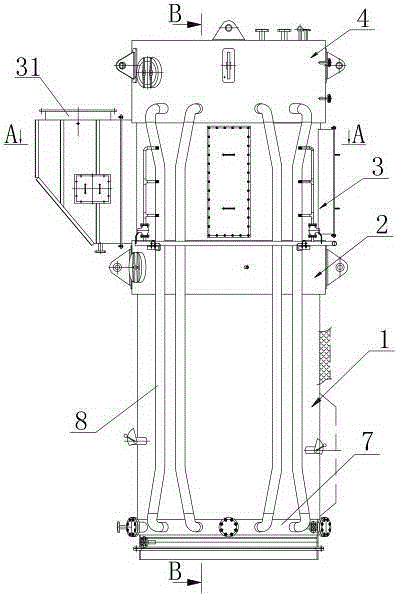

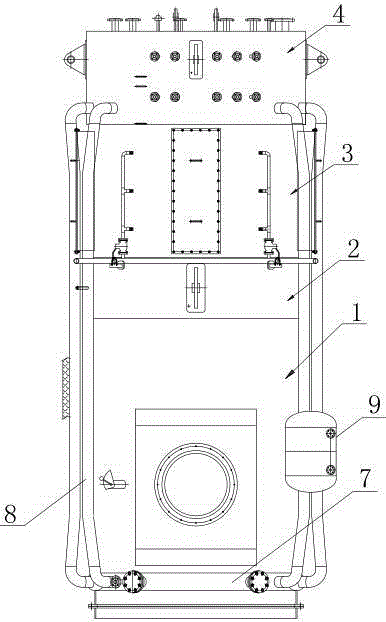

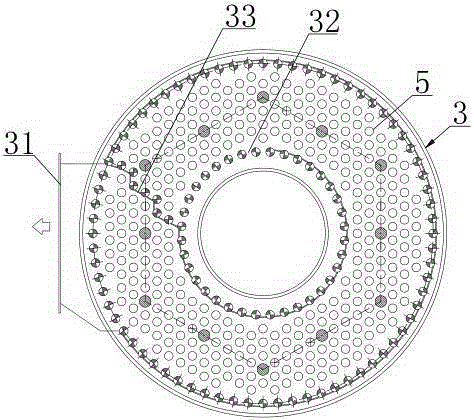

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the marine membrane wall oil-fired boiler includes: a furnace 1, a lower cylinder 2, a middle cylinder 3 and an upper cylinder 4 are arranged above the furnace 1 in sequence, and the lower cylinder 2 includes a flue gas channel and a water bag 22, Wherein the flue gas passage 21 is located inside the water bag 22, and the upper and lower ends of the flue gas passage 21 are connected with the middle cylinder body 3 and the furnace 1 respectively, and a number of heat exchange tubes 5 are uniformly densely distributed in the middle cylinder body 3, and The upper and lower ends of the heat pipe 5 communicate with the upper cylinder 4 and the water bag 22 respectively, the middle cylinder 3 is provided with a smoke outlet 31, and the furnace wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com