Mine working face simulation experimental device

A simulation experiment, working face technology, applied in the direction of measuring device, safety device, mining equipment, etc., can solve the problems of mine production loss, harm, explosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

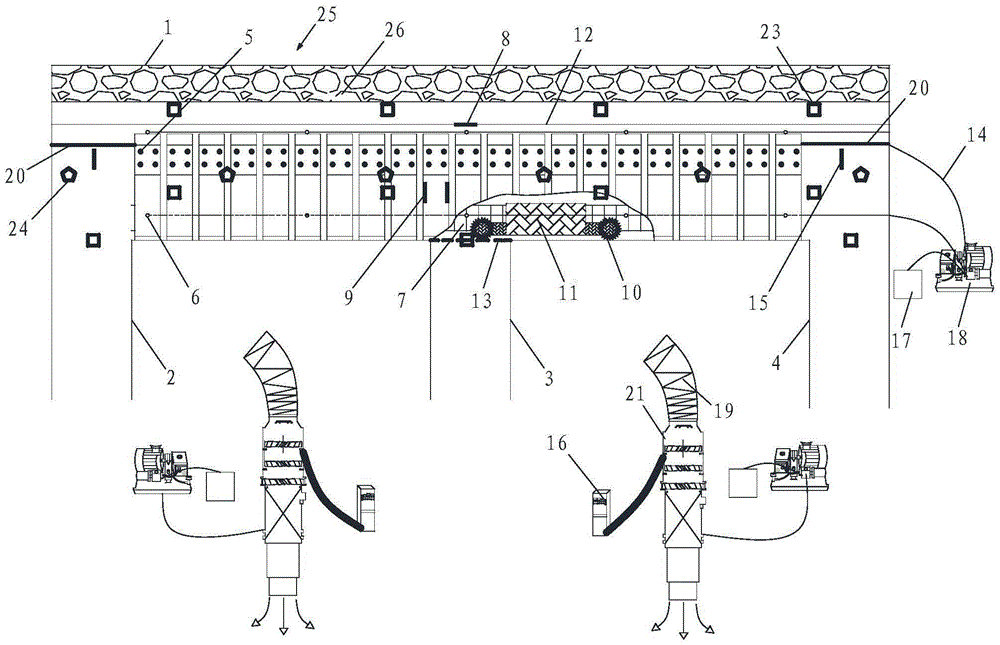

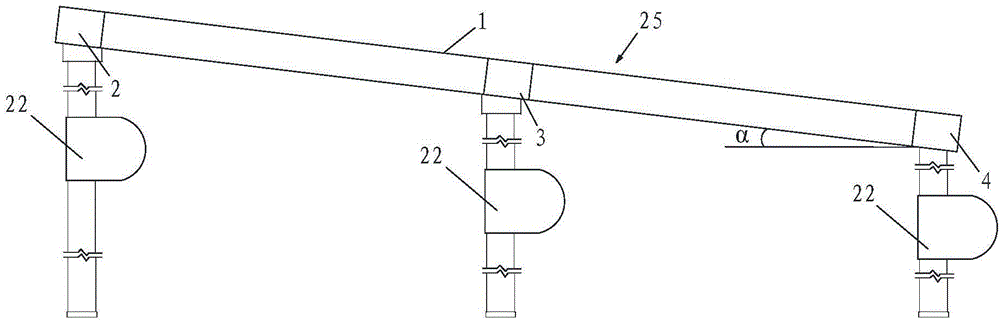

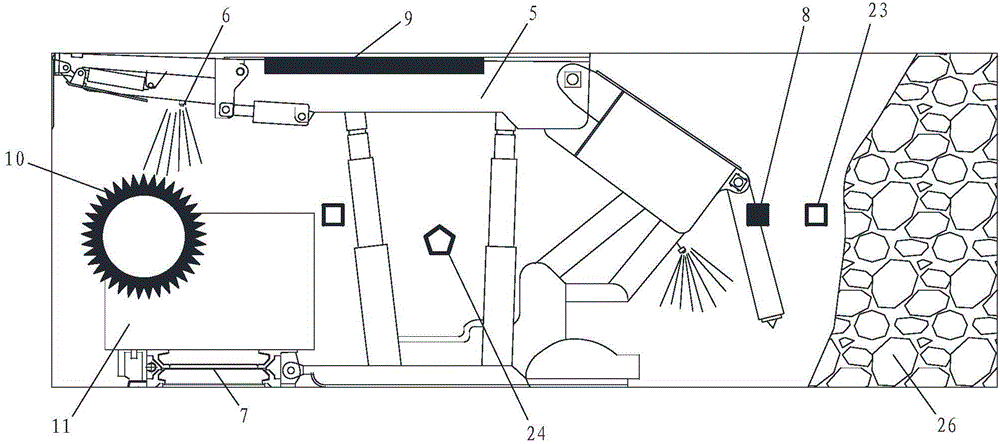

[0055] combine Figure 1 to Figure 3 As shown, a mine working face simulation experiment device includes a simulated roadway 25 , underground simulation equipment, a simulated dust source, a dust removal fan 21 , spray water supply equipment, a wind speed sensor 23 and a dust concentration sensor 24 .

[0056] The simulated roadway 25 includes a simulated main roadway 1 and three simulated side roadways, that is, a first simulated side roadway 2 , a second simulated side roadway 3 and a third simulated side roadway 4 . in,

[0057] The first simulated side roadway 2 , the second simulated side roadway 3 and the third simulated side roadway 4 are respectively located at the front, middle and rear of the same side of the simulated main roadway 1 , and are all perpendicular to the simulated main roadway 1 .

[0058] The first simulated side tunne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com