Flexible mineral fire-proof photoelectric composite cable

A photoelectric composite cable and mineral technology, applied in the direction of insulated cables, communication cables, flexible cables, etc., can solve the problems of cable restrictions, inability to monitor ambient temperature, inability to prevent and prevent fires in advance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

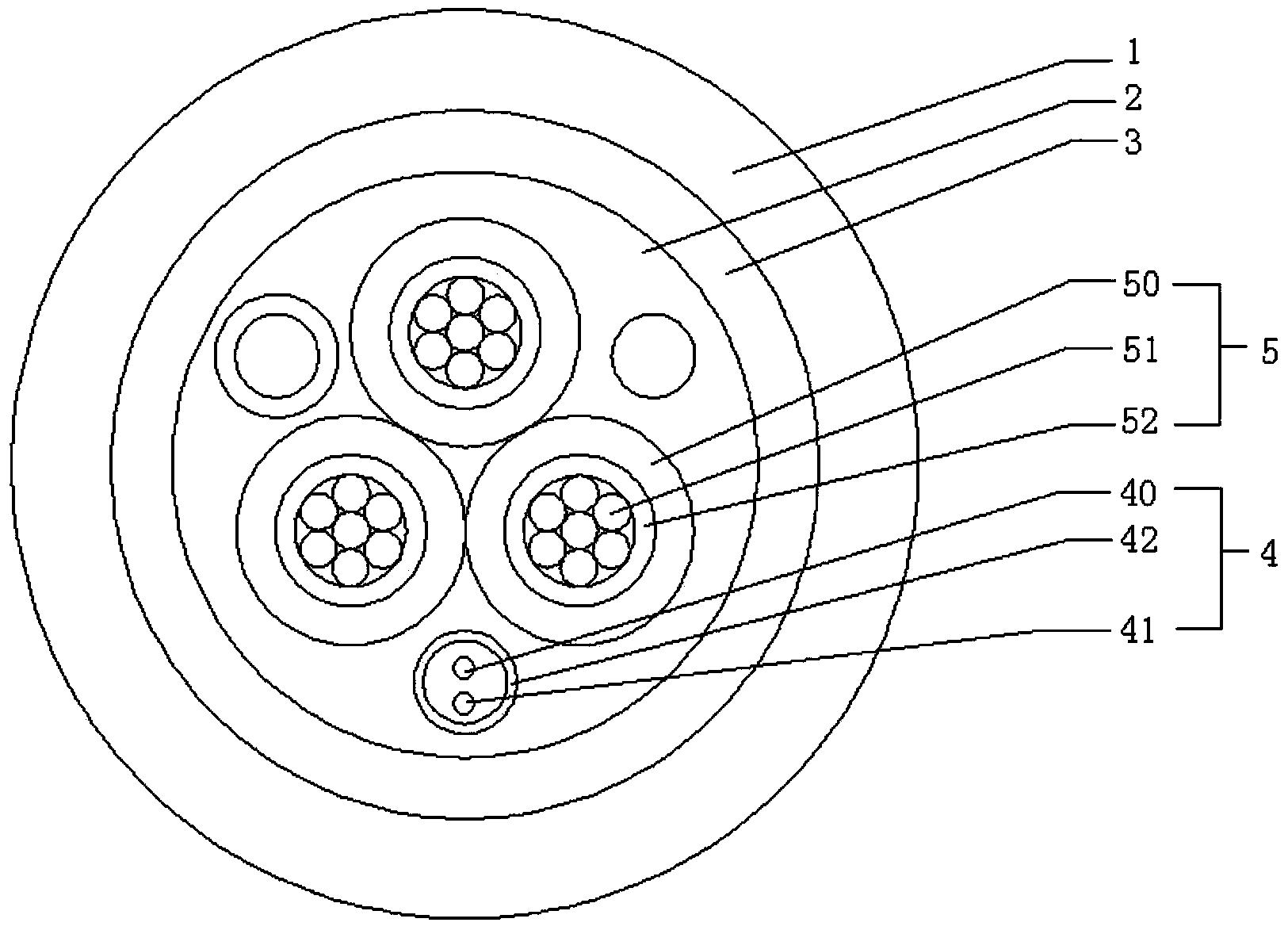

[0013] A flexible mineral fire-resistant photoelectric composite cable of the present invention comprises an outer sheath 1, a wrapping tape 3 and a mineral layer 2 arranged coaxially from the outside to the inside in a radial direction, and a plurality of cables 5 and a plurality of optical cables located in the mineral layer 2 4. The optical cable 4 wraps the multi-mode optical cable 40 and the single-mode optical fiber 41 for temperature measurement. The mineral layer 2 is filled with inorganic mineral powder which can be sintered at 950°C.

[0014] There are two advantages for the optical cable to be located in the mineral layer 2: first, the temperature of the optical fiber is the temperature inside the cable, which can be used for DTS temperature monitoring; Effectively re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com