Rheostat

A varistor and resistance wire technology, applied in sliding contact resistors and other directions, can solve the problems of vibration, accompanying noise, and resistance wire easily broken, and achieve the effect of overcoming vibration and noise, solving easy breaking and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

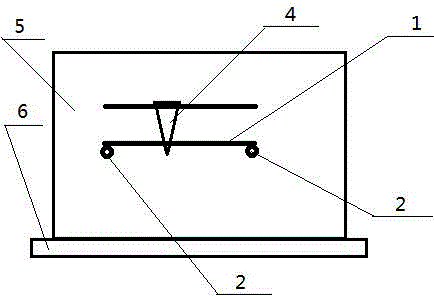

[0055] See attached figure 2 , is a structural representation of the present invention. A rheostat, comprising a panel 5, a resistance wire 1, a binding post 2 perpendicular to the panel and fixedly connected to the panel, a slide rail arranged parallel to the resistance wire, the slide rail and the panel are fixedly connected, and a slide for sliding along the slide rail 4. Both the slide rail and the resistance wire are electrically connected to the slider, and the characteristics are:

[0056]One end of the resistance wire 1 is fixedly connected to the terminal 2 and electrically connected;

[0057] The other end of the resistance wire 1 is in close contact with the binding post 2 that is matched with this end and is electrically connected with this end, and this end of the resistance wire is connected with an elastic spring that is used to pull the resistance wire and make the resistance wire receive tension. cable 3;

[0058] The other end of the elastic cable 3 is fi...

Embodiment 2

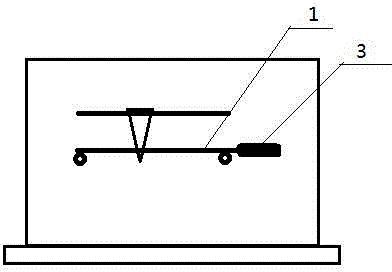

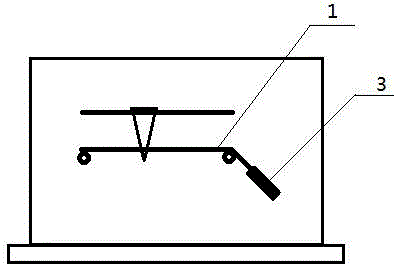

[0070] See attached image 3 , is a schematic diagram of the structure of this embodiment. A shock-absorbing rheostat, comprising a panel 5, a resistance wire 1, a binding post 2 perpendicular to the panel and fixedly connected to the panel, a slide rail arranged parallel to the resistance wire, the slide rail and the panel are fixedly connected, and are used for sliding along the slide rail Sliding piece 4, slide rail, resistance wire are all electrically connected with sliding piece, it is characterized in that:

[0071] One end of the resistance wire 1 is fixedly connected to the terminal 2 and electrically connected;

[0072] The other end of the resistance wire 1 is in close contact with the binding post 2 that is matched with this end and is electrically connected with this end, and this end of the resistance wire is connected with an elastic spring that is used to pull the resistance wire and make the resistance wire receive tension. cable 3;

[0073] The other end o...

Embodiment 3

[0080] In order to satisfy the following relationship between the terminal and the resistance wire: 1, close contact, 2, the elastic cable can well apply the tension to the resistance wire, the structure of the terminal is as follows: see the attached Figure 5 , the figure reflects the structural schematic diagram of the terminal. This figure is a front view. There is a central cylinder 21 perpendicular to the panel and one end fixedly connected to the panel. A cylinder 22 is sheathed outside the central cylinder 21, and both the central cylinder 21 and the cylinder 22 are made of conductors. In this way, the angle between the resistance wire and the elastic cable can be moderately increased so as not to cause the resistance wire not to be subjected to tension.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap