Parallel electric socket manufacturing method

A manufacturing method and parallel technology, applied in the direction of circuit/collector parts, circuits, electrical components, etc., can solve the problems of inability to move, small number, unstable voltage, etc., and achieve the advantages of single use or parallel use, product structure Simple, easy-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

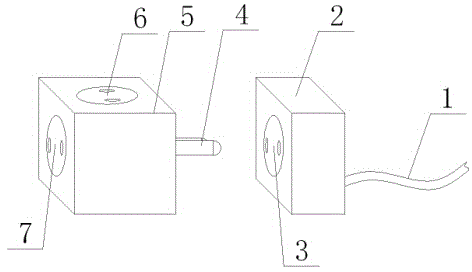

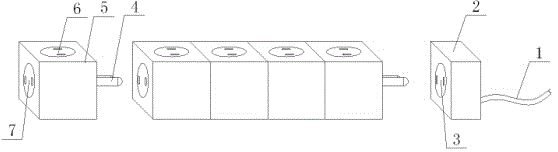

[0023] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the use status diagram of the present invention.

[0024] A method for manufacturing a parallel electrical socket of the present invention, which includes the following steps: A. Using PVC plastic particles, heating and hot-casting into a voltage stabilizing box, installing a voltage stabilizer inside the voltage stabilizing box, and Install the power cord so that one end of the power cord is connected to an external power supply, and the other end of the power cord is fixedly connected to one side of the voltage stabilization box and penetrated into the voltage stabilization box to be electrically connected to the voltage stabilizer in the voltage stabilization box. The output socket is installed on the side wall of the other side, and the output socket is fixedly connected with the voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com