Movable and modularized grain post-harvest processing device

A processing device and mobile module technology, which are applied in fruit suspension devices, chemical instruments and methods, and seed preservation by drying, etc., can solve the problems of poor quality of grain storage and incomplete grain processing and storage equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

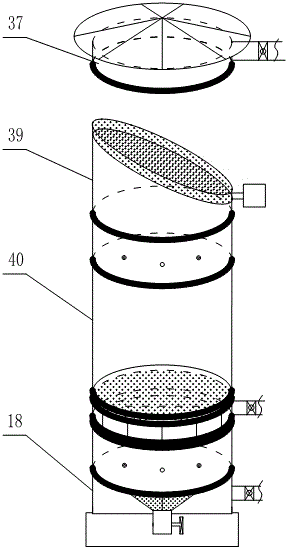

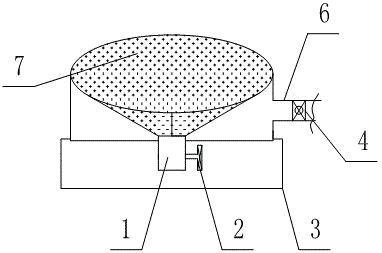

[0047] Such as Figure 1 to Figure 13 As shown, the present invention is not affected by the ground in the hilly area and the plateau area, and does not occupy the land area. The assembly and disassembly are very flexible. A plane foundation is selected as the place for the combination connection of the present invention, and the first module 18 is firmly fixed. On the basis of the plane, the second module 19 can be split into several parts through the connector 35, and the first second module 19 that has been split is first assembled and then connected to the first module 18, and then connected to the fifth module 39. Separation of grain and miscellaneous grains (separation of miscellaneous grains through vibrating sieve 24), when the grain is filled with the second module 19, connect the fourth module 38 on the top of the second module 19, then connect the fifth module 39, put grain, grain Miscellaneous separation, after the fourth module 38 of this moment is filled with gra...

no. 2 example

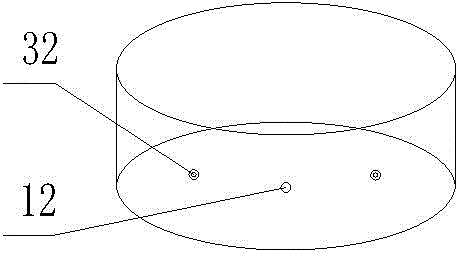

[0050] Such as Figure 1 to Figure 4 , Figure 6 to Figure 9 , Figure 11 and Figure 12 As shown, when the height of the stacking of the second module 19 does not affect the penetration of the air flow, the fourth module 38 can be connected without connecting the first module 18. After the first module 18 is stabilized, the second module 19 and the fifth module 39 are connected in turn, and the grain is released. Separation of miscellaneous grains, when the grain is filled with the second module 19, another second module 19 is connected on the top of the second module 19, and then the fifth module 39 is connected, grain is put, and miscellaneous grains are separated. After the second module 19, take off the fifth module 39, ensure that the grain is not higher than the upper edge of the uppermost second module 19, connect the third module 37, and check the reinforcement. Put the temperature-sensing probe into the temperature-sensing hole 12, connect the temperature-sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com