Blisk electrolysis slotting machining annular electrode and technology method

A technology of integral blisks and ring electrodes, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost, unstable quality, and low efficiency, and achieve low cost, long processing cycle, and Guarantee the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

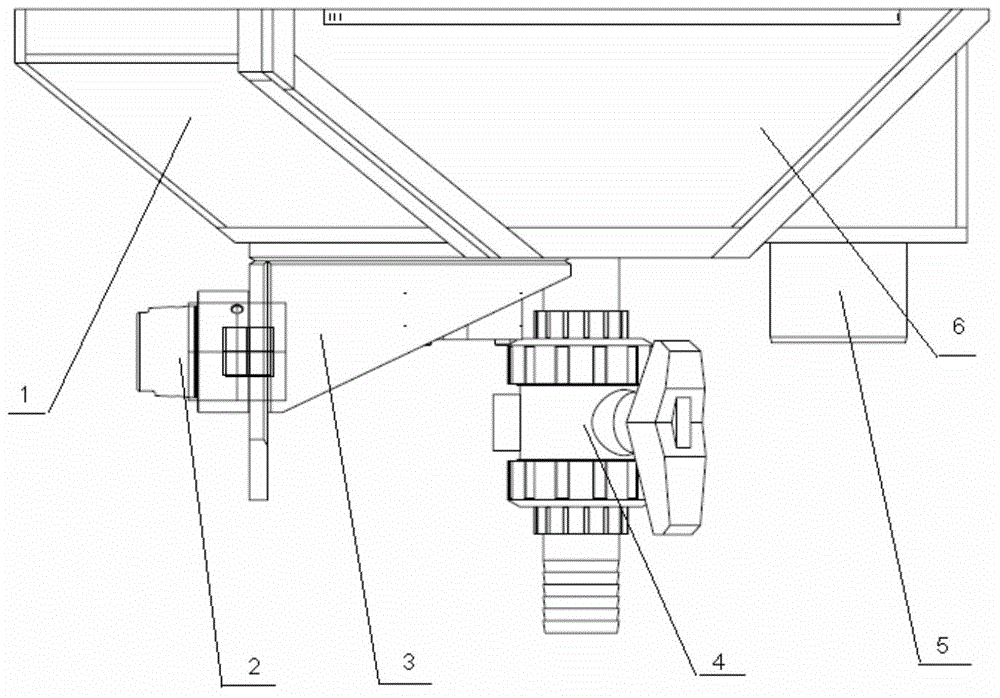

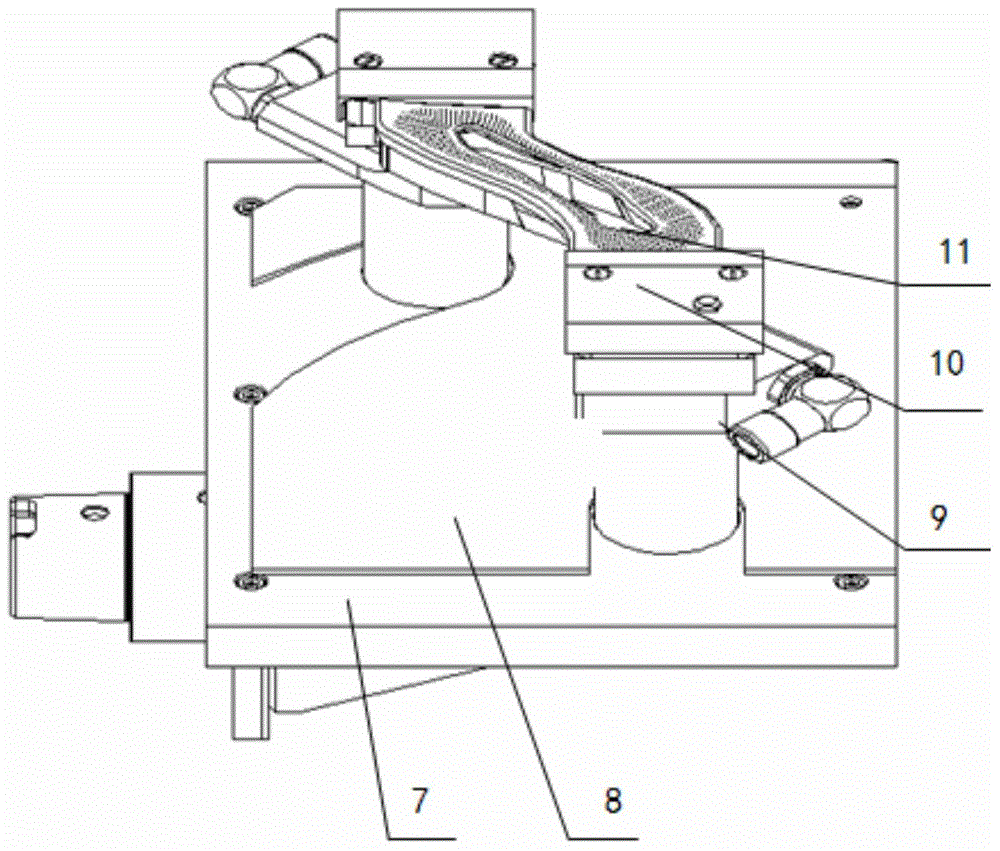

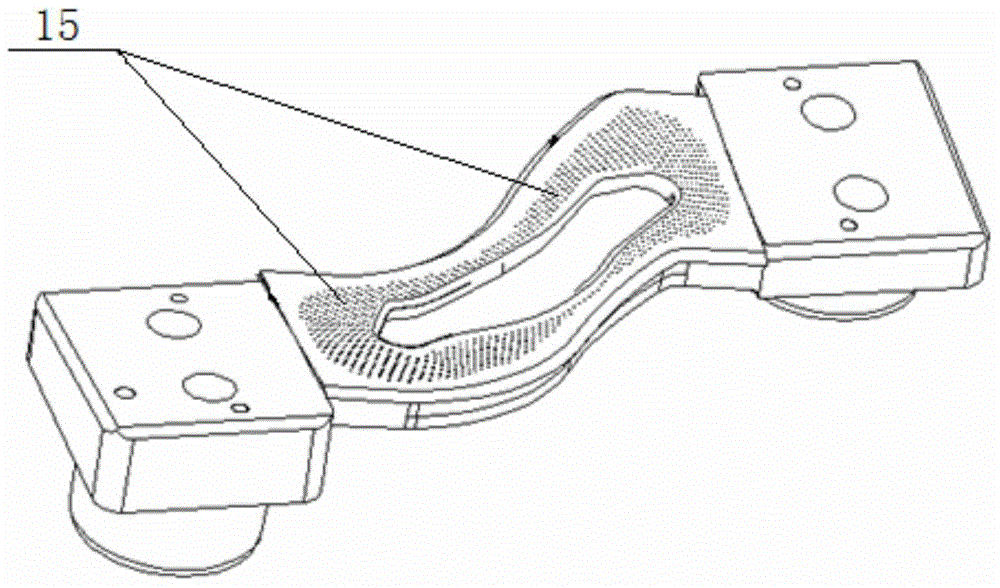

[0023] The grooved annular electrode is composed as follows: electrolyte tank 1, HSK hydraulic chuck 2, adapter plate 3, electrolyte discharge valve 4, electrolyte overflow port 5, electrolyte tank front baffle 6, working cathode Components and base 7; the working cathode components are composed as follows: a sacrificial anode protection plate 8, an electrolyte inlet pipe joint 9, an insulating briquetting block 10, and a working cathode 11; the electrolyte inlet pipe joint 9 is specifically two, The electrolyte inlet pipe joint 9 is respectively connected to the working cathode 11 through the insulating pressing block 10, and the integral blisk workpiece 14 is connected to the working cathode 11. The sacrificial anode protection plate 8 is located at the lower end of the working cathode, and the working cathode assembly is located at On the base 7, the working cathode assembly and the base 7 are located in the electrolyte tank 1. The HSK hydraulic chuck 2 is quickly positioned...

Embodiment 2

[0036] The grooved annular electrode is composed as follows: electrolyte tank 1, HSK hydraulic chuck 2, adapter plate 3, electrolyte discharge valve 4, electrolyte overflow port 5, electrolyte tank front baffle 6, working cathode Components and base 7; the working cathode components are composed as follows: a sacrificial anode protection plate 8, an electrolyte inlet pipe joint 9, an insulating briquetting block 10, and a working cathode 11; the electrolyte inlet pipe joint 9 is specifically two, The electrolyte inlet pipe joint 9 is respectively connected to the working cathode 11 through the insulating pressing block 10, and the integral blisk workpiece 14 is connected to the working cathode 11. The sacrificial anode protection plate 8 is located at the lower end of the working cathode, and the working cathode assembly is located at On the base 7, the working cathode assembly and the base 7 are located in the electrolyte tank 1. The HSK hydraulic chuck 2 is quickly positioned...

Embodiment 3

[0044] The grooved annular electrode is composed as follows: electrolyte tank 1, HSK hydraulic chuck 2, adapter plate 3, electrolyte discharge valve 4, electrolyte overflow port 5, electrolyte tank front baffle 6, working cathode Components and base 7; the working cathode components are composed as follows: a sacrificial anode protection plate 8, an electrolyte inlet pipe joint 9, an insulating briquetting block 10, and a working cathode 11; the electrolyte inlet pipe joint 9 is specifically two, The electrolyte inlet pipe joint 9 is respectively connected to the working cathode 11 through the insulating pressing block 10, and the integral blisk workpiece 14 is connected to the working cathode 11. The sacrificial anode protection plate 8 is located at the lower end of the working cathode, and the working cathode assembly is located at On the base 7, the working cathode assembly and the base 7 are located in the electrolyte tank 1. The HSK hydraulic chuck 2 is quickly positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com