Mold for dry casing production

A dry-type sleeve and mold technology, applied in the field of optical fiber and cable manufacturing equipment, can solve problems such as affecting the transmission performance and temperature performance of the optical cable, unstable sleeve size, affecting the performance of the optical cable, etc. Round, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

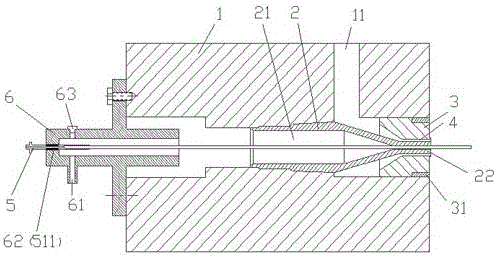

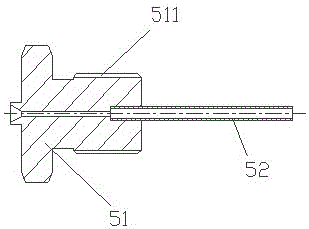

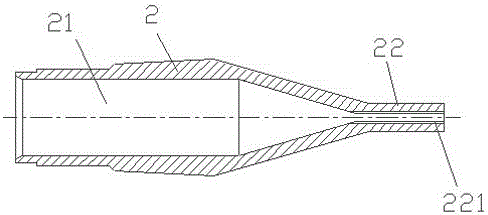

[0018] refer to figure 1 , 2 , 3, and 4, the present invention relates to a mold for dry casing production, including a mold core 2 and a mold cover 3 assembled on the extruder head 1, the mold core 2 has a through hole 21 and extrusion Nozzle 22, the outer periphery of the extrusion nozzle 22 forms an extrusion gap 4 with the extrusion port of the die cover 3, and the extrusion gap 4 communicates with the material inlet 11 of the extruder head 1. The die cover 3 is connected to the extruder head 1 through a fastener 31 , and the fastener 31 can be connected to the extruder head 1 through threads or screws. The mold also includes a hollow threading needle 5, one end of the threading needle 5 passes through the through hole 21 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com