An improved heavy oil thermal recovery method and device

A technology for thermal recovery of heavy oil and oil layers, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of steam drive and low recovery rate, so as to improve oil recovery and reduce steam channeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

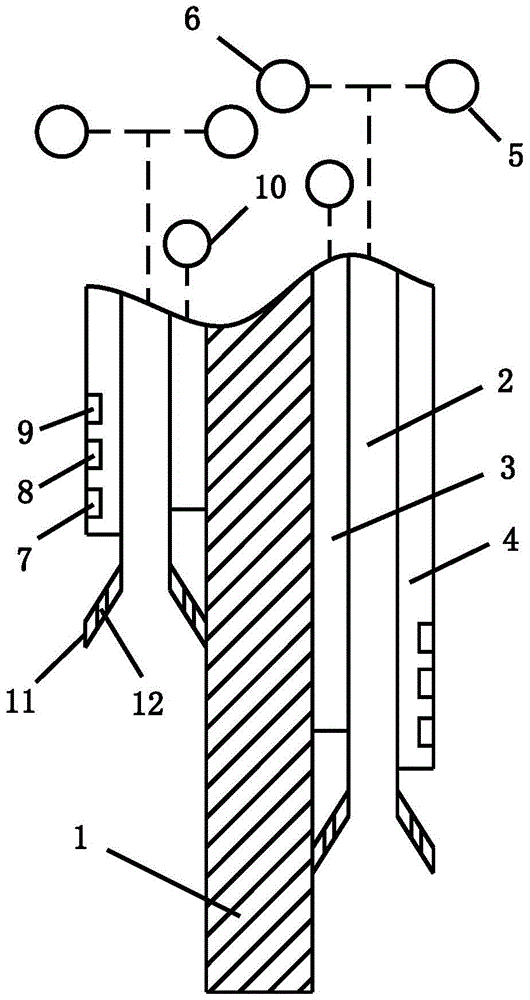

Image

Examples

Embodiment 1

[0029] A method of using the above-mentioned heavy oil thermal recovery device, comprising the following steps:

[0030] A. Several oil wells are set in the production area, so that each oil well runs through each oil layer in the production area, and the heavy oil thermal recovery device is lowered into the oil well, and a gas injection device is arranged in each oil layer;

[0031] B. Use the gas injection pipeline 2 to inject steam into each oil layer, the injection pressure is 3.7MPa, the steam dryness is 25%, the steam temperature is 300°C, and the injection speed is 1700m 3 / h, the injection time is 30h;

[0032] C. After the steam injection is completed, carry out the first stewing well, and the stewing time is 40h;

[0033] D. After the first soaking well, carry out secondary steam injection into each oil layer, and perform the second soaking well after the second steam injection, and repeat this step several times until the pressure drop rate in the well during the w...

Embodiment 2

[0045] A method of using the above-mentioned heavy oil thermal recovery device, comprising the following steps:

[0046] A. Several oil wells are set in the production area, so that each oil well runs through each oil layer in the production area, and the heavy oil thermal recovery device is lowered into the oil well, and a gas injection device is arranged in each oil layer;

[0047] B. Use the gas injection pipeline 2 to inject steam into each oil layer, the injection pressure is 4.3MPa, the steam dryness is 30%, the steam temperature is 260°C, and the injection speed is 2200m 3 / h, the injection time is 25h;

[0048] C. After the steam injection is completed, carry out the first stewing well, and the stewing time is 40h;

[0049] D. After the first soaking well, carry out secondary steam injection into each oil layer, and perform the second soaking well after the second steam injection, and repeat this step several times until the pressure drop rate in the well during the w...

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 2, and will not be described in detail here. The difference is that in step D, after the completion of the second brine well, the check valve 10 is first opened, and the auxiliary injection pipeline 3 is used to check the oil in the oil layer. Crude oil is pre-extracted, and the amount of each pre-extraction is controlled at 0.3 to 0.4 tons. With the increase in the number of brine wells, the amount of each pre-extraction gradually decreases. Pre-extraction after soaking the well can reduce the air resistance of steam in the oil layer, improve the fluidity of heavy oil in the oil layer, and improve the reaction between steam, hot water and the catalyst injected together with hot water and heavy oil, thereby improving the oil output. oil volume.

[0061] After experimental comparison, the comparison of the average daily oil production and the average daily steam consumption using the existing technology (initial steam h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com