An Intelligent Carburetor for Small General Purpose Gasoline Engines

A general-purpose gasoline and carburetor technology, applied to machines/engines, etc., can solve the problems of unsatisfactory energy saving and emission reduction, large exhaust emissions, and high manufacturing costs, achieving low manufacturing costs, precise control of air-fuel ratio, and stable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

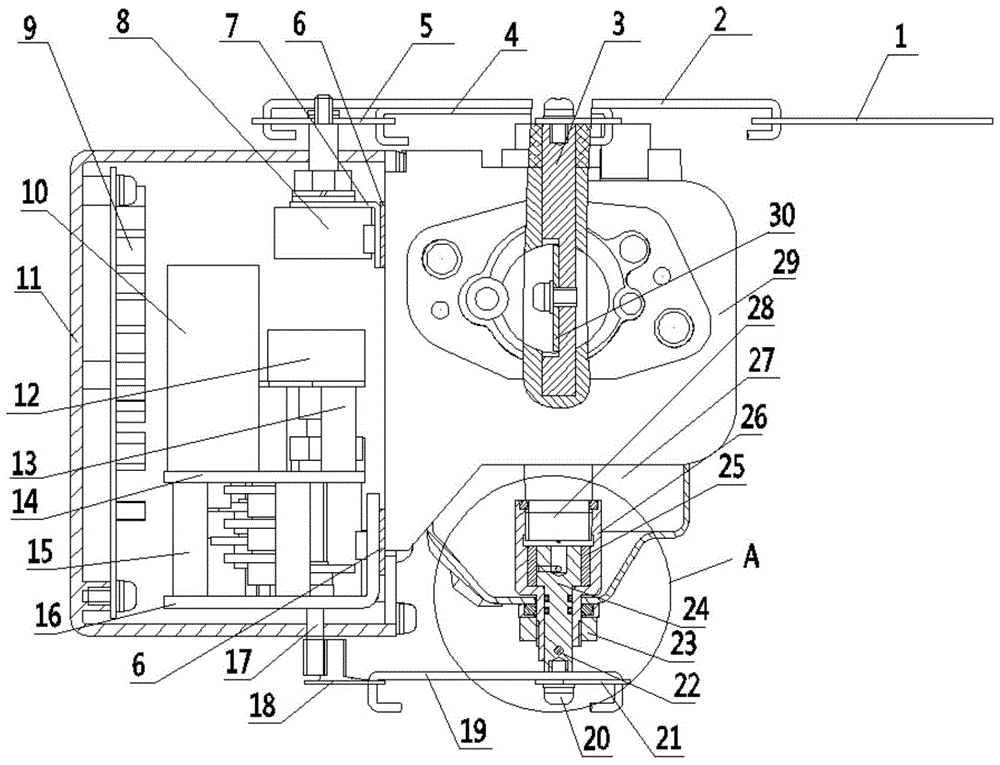

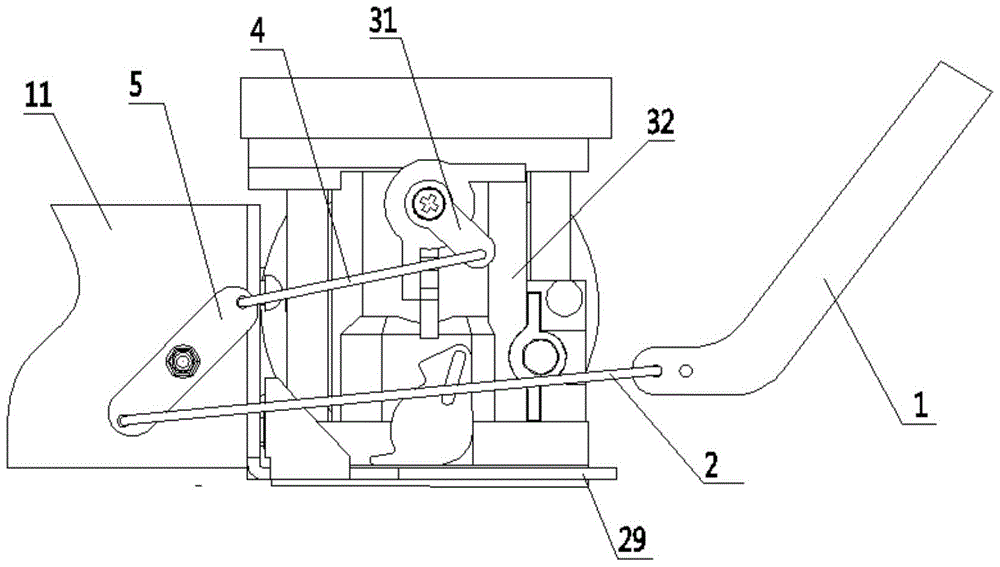

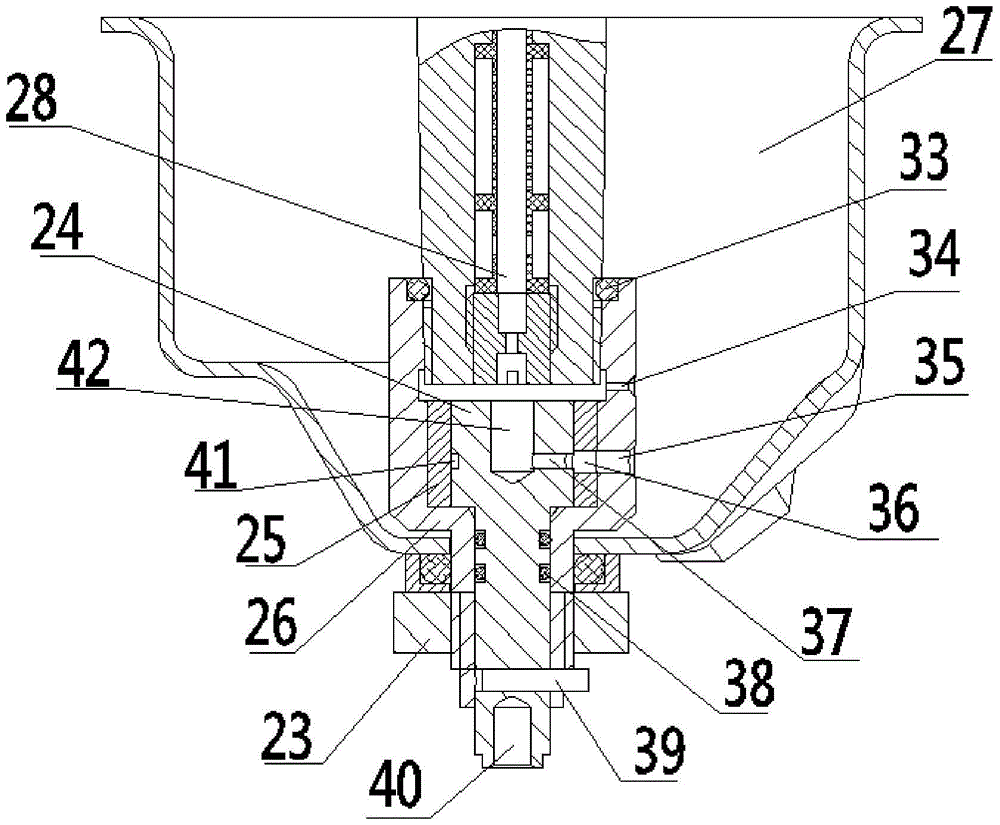

[0028] A smart carburetor for small general-purpose gasoline engines, such as figure 1 and figure 2 As shown, it includes a vertically arranged carburetor body 32, an electric actuator and a flow control valve. The electric actuator includes an open casing 11, a controller 9 and a servo motor 10, and is fixedly arranged on the outer wall of the carburetor body 32. There is a load-bearing angle plate 29, and the opening of the open shell 11 is fixedly connected with the load-bearing angle plate 29. The upper part of the open shell 11 is vertically fixed with a first rotary potentiometer 8, and the rotating shaft of the first rotary potentiometer 8 faces Vertically upwards and protruding from the top of the open hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com