Device and method for non-contact detection of size and angle of large-size laser neodymium glass wrapping

A non-contact, neodymium glass technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high labor intensity, low efficiency, and affecting the optical quality of the test surface, so as to achieve reduced labor intensity, accurate measurement, and convenient measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and implementation, but the protection scope of the present invention should not be limited by this.

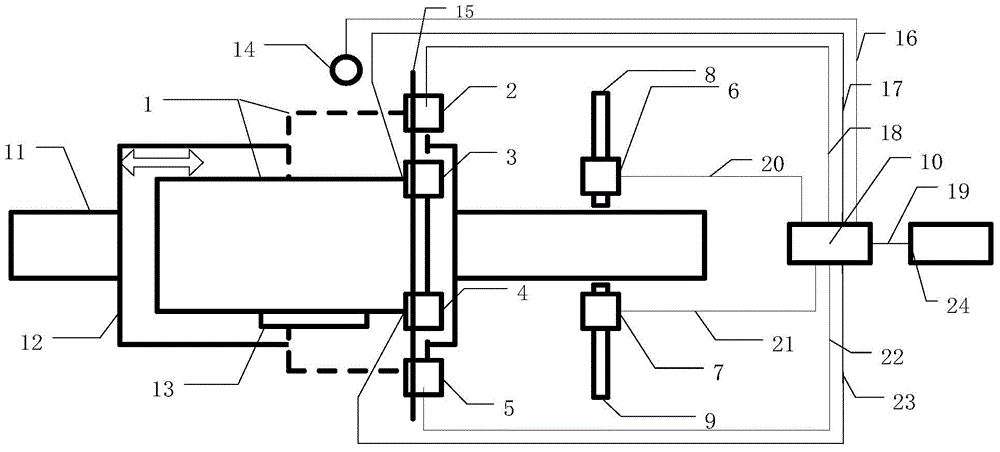

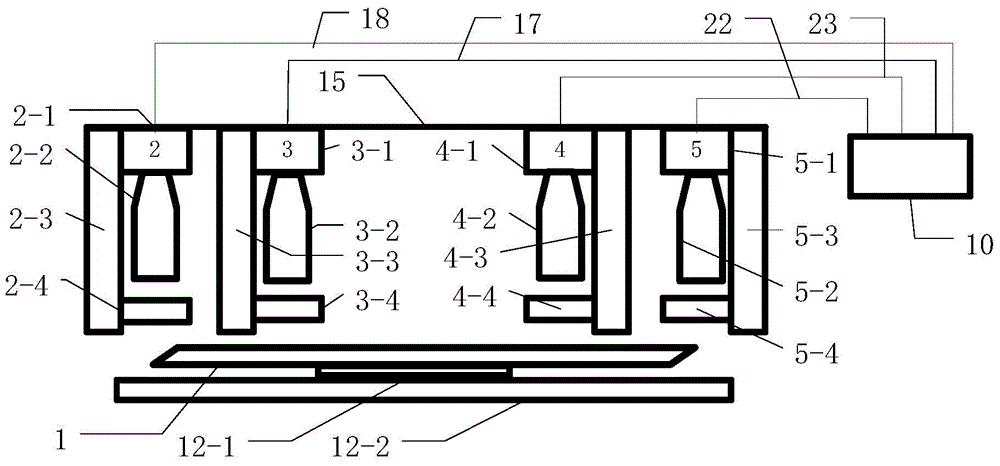

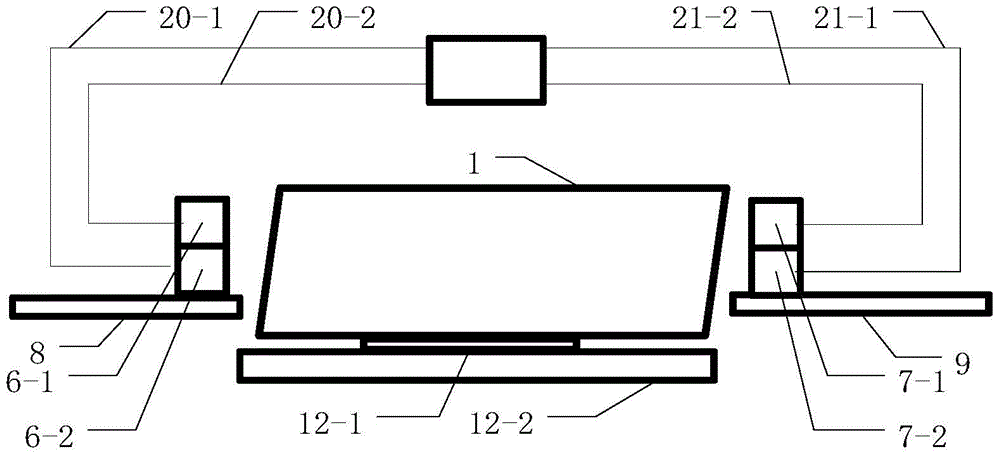

[0038] see first figure 1 , figure 2 , image 3 , figure 1 It is a schematic top view implementation of the large-size laser glass neodymium glass edging size and angle detection device of the present invention, figure 2 It is a schematic diagram (left view) of the size structure of the non-contact detection of large-size laser neodymium glass cladding of the present invention. image 3 It is a schematic diagram (left view) of the non-contact detection of large-size laser neodymium glass edging angle structure of the present invention. As can be seen from the figure, the large-size laser glass neodymium glass edging size and angle detection device of the present invention is composed of:

[0039] Four area scan cameras: the first area scan camera 2-1, the second are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com