An ultrasonic flowmeter peak detection method and compensation system

A peak detection and ultrasonic technology, applied in the field of ultrasonic flowmeter measurement, can solve problems such as inaccurate measurement, and achieve the effects of improved accuracy, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] The ultrasonic flowmeter peak detection method of the present invention comprises the following steps:

[0016] (1) Provide a reference voltage, measure the voltage on the capacitor, and calculate the difference between the voltage and the reference voltage to obtain the forward conduction voltage drop of the diode;

[0017] (2) When measuring the peak value of the normal ultrasonic signal, the voltage detected on the capacitor plus the forward conduction voltage drop of the diode obtained in step (1) is used as the peak signal voltage to calculate the flow rate.

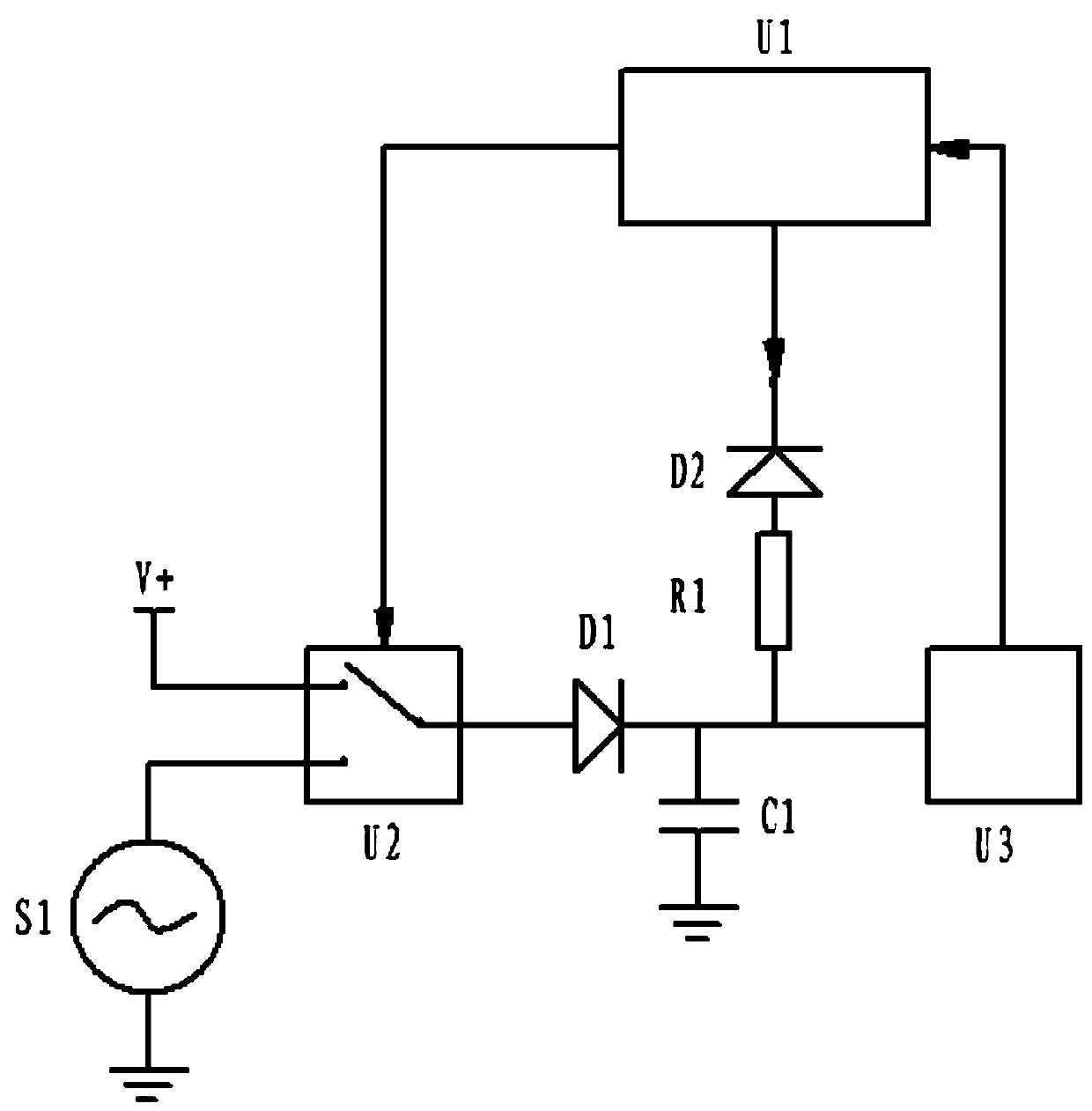

[0018] The principle diagram of the compensation system for the peak detection of the ultrasonic flowmeter for realizing the above-mentioned detection method in the present invention is as follows figure 1 As shown, it includes MCU module U1, diode D1, electronic sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com