Experimental device for flow and heat transfer characteristics of curved single passage of subcritical energy reactor coolant

A technology of heat transfer characteristics and experimental device, which is applied in the field of a new type of experimental device for heat transfer characteristics of a curved single-channel flow of coolant in a nuclear reactor, and can solve problems such as the inability to simulate the flow and heat transfer characteristics of a subcritical cladding coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

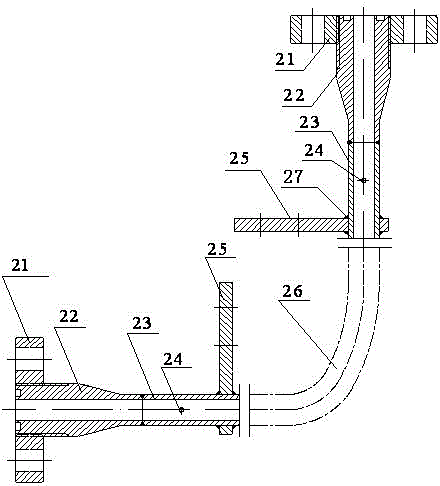

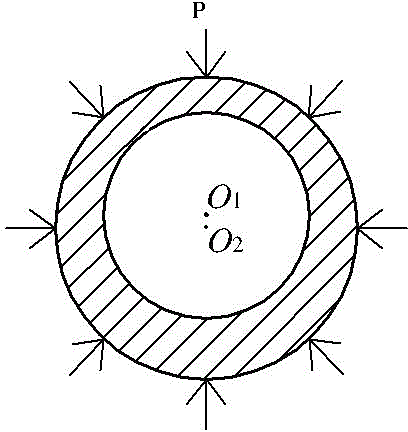

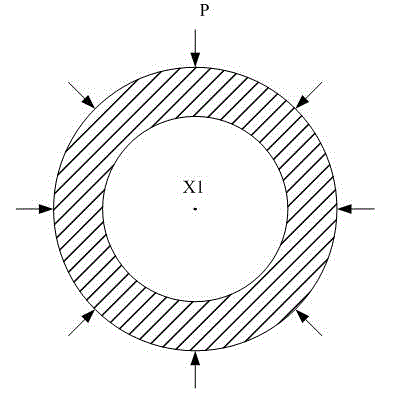

[0026] Such as Figure 1 to Figure 3 shown.

[0027] Based on the ITER-driven subcritical mixed reactor fuel cladding curve equation, the present invention selects the curved channel with the largest curvature and the highest steam content near the inner cladding outlet as a typical curved geometric characteristic for the purpose of thermal safety research. The invention utilizes direct current heating to heat the eccentric bend pipes with different circumferential wall thicknesses to realize circumferential non-uniform heating, so as to simulate the circumferential non-uniform distribution characteristics of heat flux density in subcritical reactor coolant channels. The inner diameter of the runner is consistent with the inner diameter of the subcritical reactor coolant channel ( φ =16 mm), the outer diameter and eccentricity of the eccentric elbow are determined by the structural strength requirements and heat flux distribution requirements. The eccentric bend is obtained ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com