A two-way operating mechanism

A two-way operation, action mechanism technology, applied in contact drive mechanism, electrical components, electrical switches and other directions, can solve the problems of complex processing and assembly, no interlocking, misoperation, etc., to achieve simple processing, reduce failure rate, and avoid mistakes. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

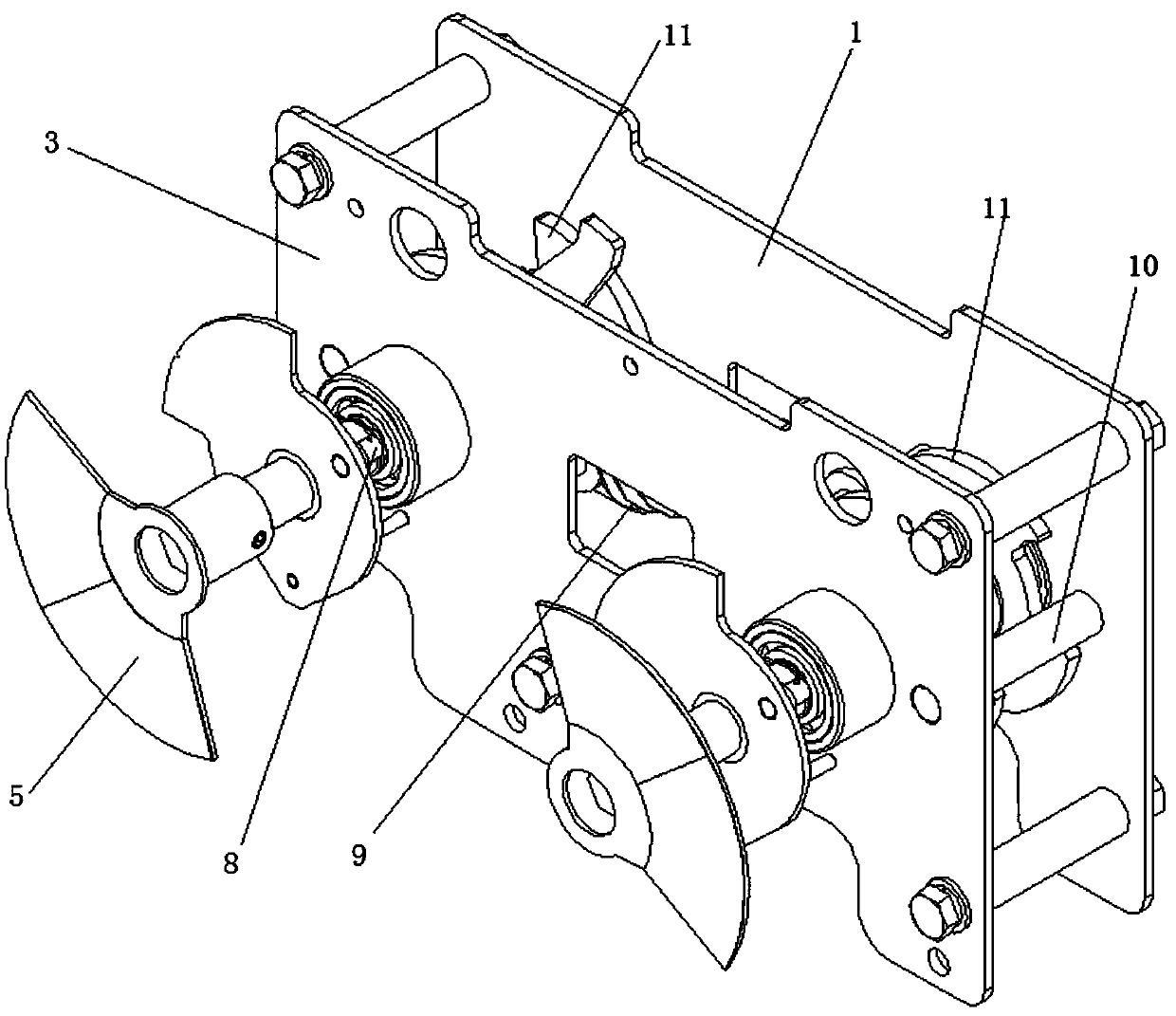

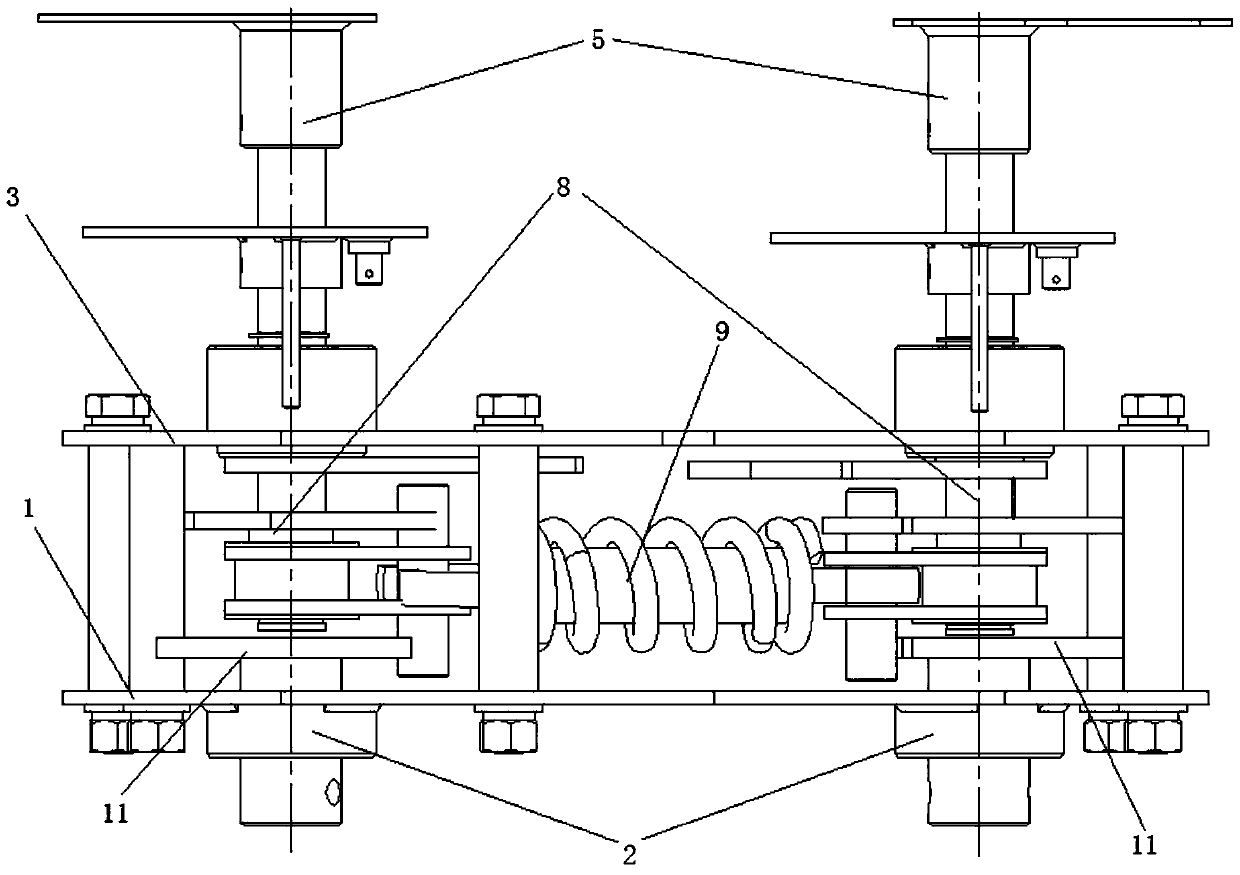

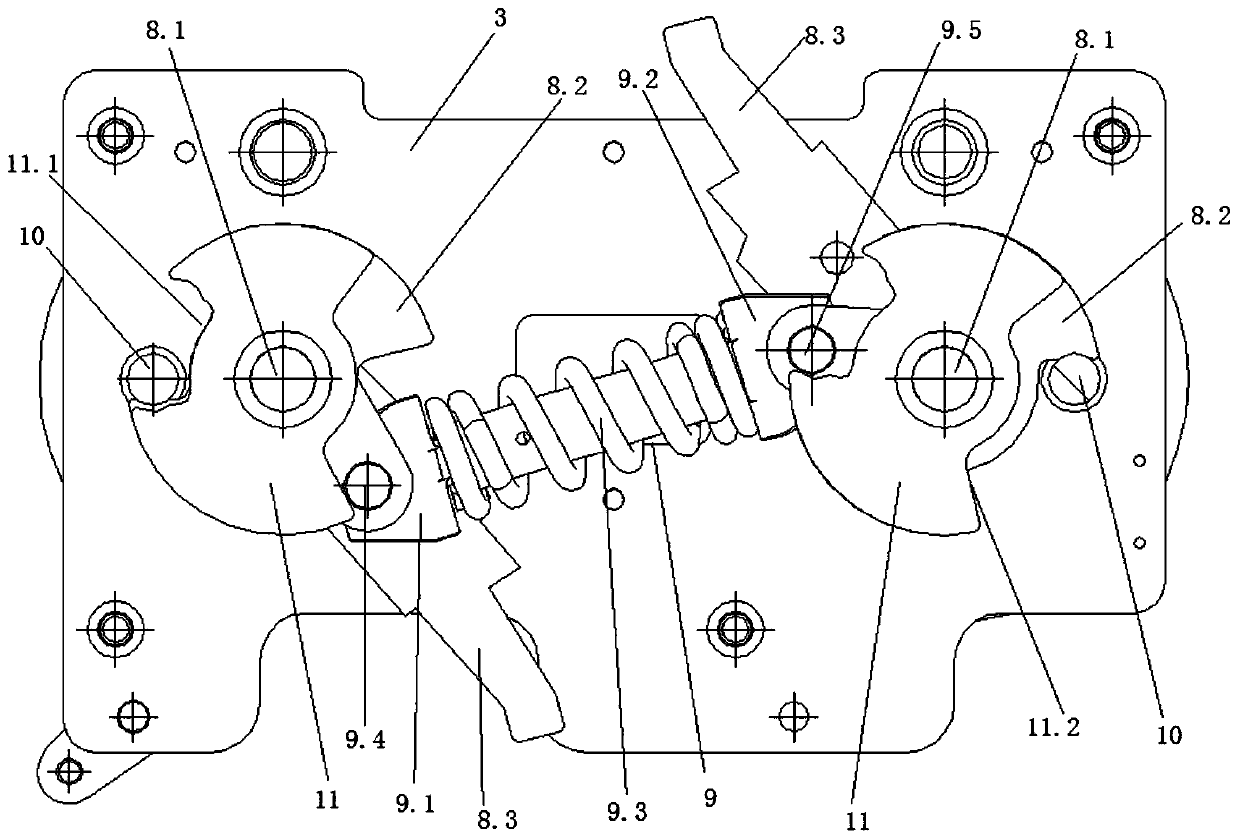

[0044] The two-way operating mechanism in this embodiment includes a front mounting plate 3, a rear mounting plate 1, two mechanical action mechanisms 8, two spacer posts 10, a spring action mechanism 9, two driven spacer plates 11 and a driven shaft joint 2; as Figure 1-Figure 9 shown.

[0045]The mechanical action mechanism 8 includes a rotating shaft 8.1, a manual operation plate 5, a limit plate 8.2 and a baffle plate 8.3; as Figure 7 and Figure 8 shown.

[0046] The spring action mechanism 9 includes a first shift fork 9.1, a second shift fork 9.2, a compression spring 9.3, a first rotating shaft limit post 9.4, a second rotating shaft limit post 9.5, a first rotating connecting plate 9.6 and a second rotating connecting plate 9.7 ;like Figure 9 shown.

[0047] The rear mounting plate 1 in this embodiment is arranged in parallel with the front mounting plate 3 through bolt connection; two mechanical action mechanisms 8 are all arranged on the front mounting plate...

Embodiment 2

[0060] Compared with Embodiment 1, a set of mechanical self-locking mechanism 6 is added to the bidirectional operating mechanism in this embodiment, and the rest of the mechanisms are the same as those in Embodiment 1. Such as Figure 10 and 11 shown.

[0061] The mechanical self-locking mechanism 6 in this embodiment includes an indicator plate 6.1, a first linkage plate 6.2, a connecting plate 6.3, a second linkage plate 6.4 and a lead-out shaft 6.5; the indicator plate 6.1 is fixedly arranged on the rotating shaft 8.1; the first linkage plate One end of 6.2 is fixedly connected to indicator plate 6.1, and the other end is fixedly connected to one end of connecting plate 6.3; the other end of connecting plate 6.3 is fixedly connected to one end of second linkage plate 6.4; the other end of second linkage plate 6.4 is fixedly connected to lead-out shaft 6.5; The middle positions of the two linkage plates 6.4 are set on the front mounting plate 3 through the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com