Switch and bidirectional automatic-switching looped network equipment earthing switch comprising same

A grounding switch and switch technology, applied in the field of switches, can solve the problems of complex processing and assembly, no interlock, misoperation, etc., and achieve the effect of simple processing, simple and convenient installation, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, a switch is taken as an example to further describe its structure and working process.

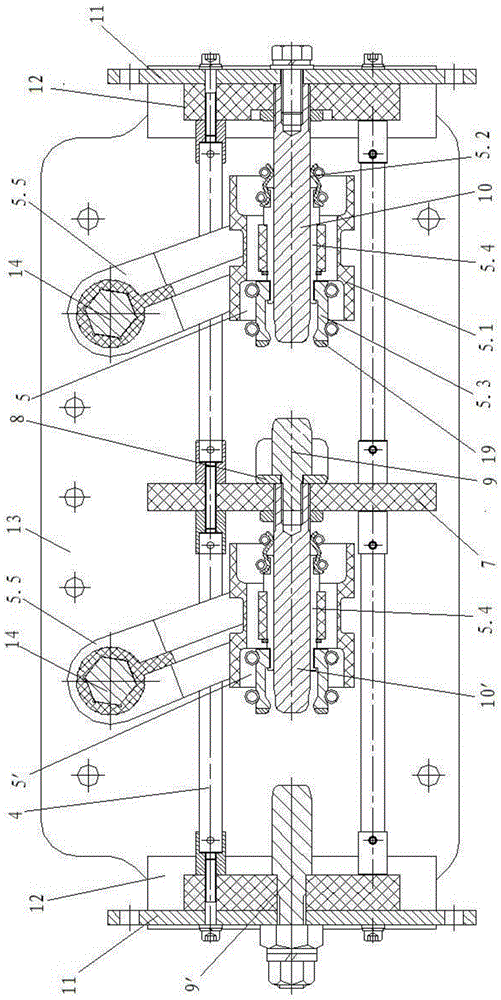

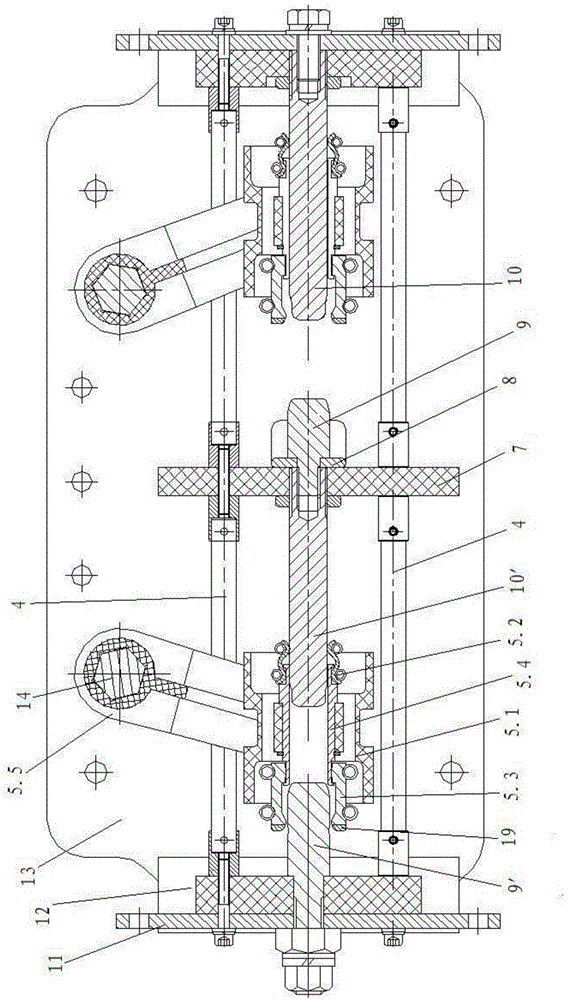

[0042] Such as Figure 1-3 As shown: the switch in this embodiment includes an output copper bar 8, an intermediate insulating mounting plate 7, a closing switch on the left and a closing switch on the right.

[0043] The output copper bar 8 in the switch of this embodiment is connected to the intermediate insulating mounting plate 7; the closing switch on the left side and the closing switch on the right side are arranged on the left and right sides of the switch bracket body 13 at the same time, and the closing switch on the left side The gate switch and the closing switch on the right side are located on both sides of the intermediate insulating mounting plate 7 .

[0044] The closing switches on the right side all include a main shaft 14 , an insulating mounting plate 12 , a connecting copper bar 11 , a first static contact 10 , a movable electrode assembly ...

Embodiment 2

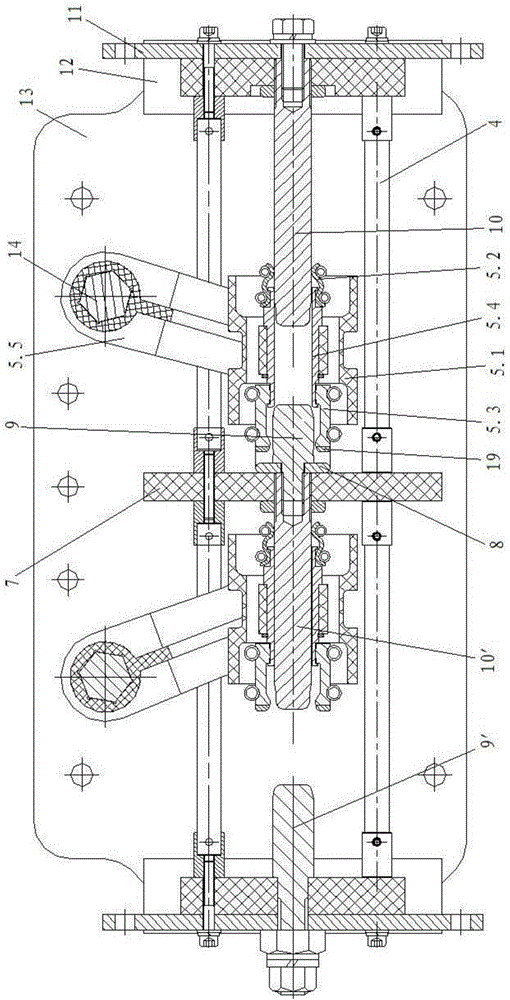

[0059] In this embodiment, taking the grounding switch of the bidirectional automatic switching ring network equipment composed of three switches as an example, its structure and working process are further described. Such as Figure 4 , Figure 5 and Figure 6 shown.

[0060] The load switch in this embodiment is formed by connecting three switches in Embodiment 1 in series. For the specific structure and working process of the switch, refer to the description in Embodiment 1.

[0061] In this embodiment, the left closing switch in the grounding switch and the right closing switch in the grounding switch respectively share the same main shaft 14 .

[0062] In this embodiment, the output copper bar 8 in the grounding switch is a grounding copper bar, and is connected to the switch bracket body 13 . Observation windows 13.1 are provided on both side plates of the switch bracket body 13 . The grounding switch is designed with observation windows on both sides of the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com