Integrated multi-layer metal sintered felt filter disc

A multi-layer metal and sintered felt technology, which is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems such as difficult cleaning of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

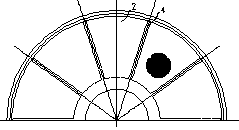

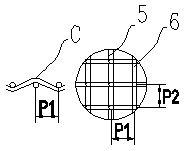

[0018] In order to make the surface of the sintered felt stronger, the two sides of the sintered material are attached with 48 and 40 mesh metal multi-mesh, and the middle is a sandwich-type filter material with a simple structure of the support material. The warp and weft of the support material, and the concave and convex parts are repeatedly woven to form a multi-layer integral sintered layer integrated filter felt with cross-sectional gaps.

[0019] The upper and lower sides of the sintered felt are first sintered with high-density 48-mesh and 40-mesh metal mesh at a relatively close melting point, and then sintered with 8-mesh intermediate standard metal mesh or special-mesh woven special-shaped metal mesh as a support material. secondary sintering. In order to improve the compressive capacity of the support material and the sintered filter material, first passivate and sinter the concave and convex parts of the metal braided mesh as the support material during sintering,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com