Intelligent injection molding machine

An intelligent injection molding machine, injection molding machine technology, applied in the field of intelligent injection molding machines, can solve the problems of not reaching the theoretical height, troublesome injection molding production users, high cost, etc., and achieve the effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

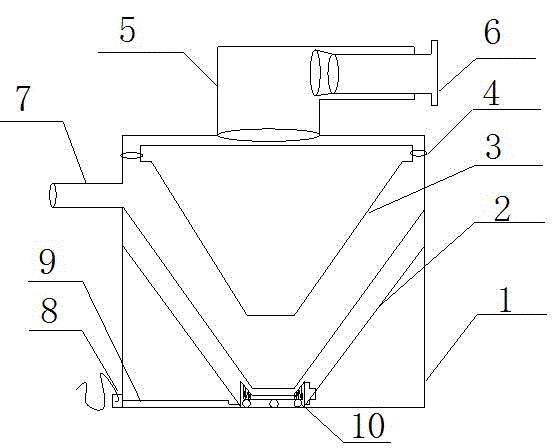

[0009] like figure 1 The shown intelligent injection molding machine includes an injection molding machine main body 1, a V-shaped lower mold 2, a V-shaped upper mold 3, a power connection port 8 and a wire 9. The V-shaped lower mold 2 is fixed on the lower part of the injection molding machine main body 1, The V-shaped upper mold 3 is fixed on the top of the main body 1 of the injection molding machine through the sliding ring 4, the top of the main body 1 of the injection molding machine is provided with an air pump 5, and one end of the air pump 5 is fixed with a manual lever 6. The left end of the machine main body 1 is fixed with a feed port 7, the left bottom end of the injection molding machine main body 1 is fixed with a power supply connection port 8, and the bottom of the injection molding machine main body 1 is provided with an intelligent repair device 10, and the intelligent repair device 10 It is connected with the power connection port 8 through a wire 9. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com