Manual quick drying device for correction liquid

A correction fluid and quick-drying technology, applied to manual devices, printing, erasers, etc., can solve problems such as slow drying, easy pollution during writing, and achieve the effect of not occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

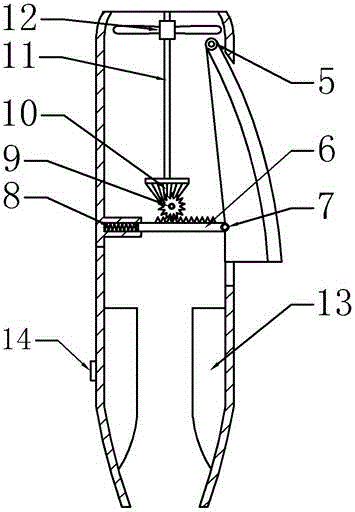

[0013] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

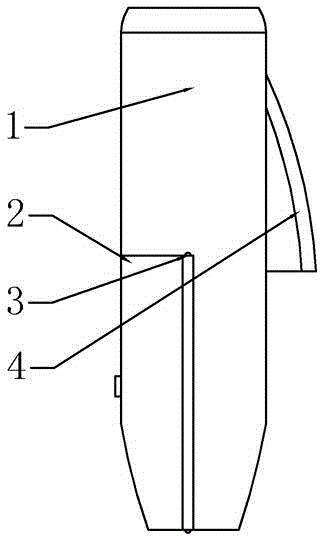

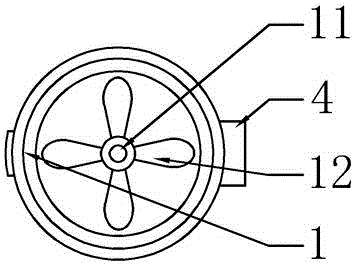

[0014] Such as Figure 1-3 Shown is the structural representation of the present invention.

[0015] The manual correcting liquid quick-drying device of the present invention, the main part is made up of housing 1, pressing handle 4, toothed rod 6, spring 8, gear 9, circular mirror gear 10, connecting rod 11 and fan blade 12. It is characterized in that: the shell 1 is rocket-shaped, and the upper and lower ends are cut open; the pressing handle 4 is connected to the shell 1 on the upper right part of the shell 1, and the user presses it to make the lower end move to the left during operation; the belt The toothed rod 6 is horizontally connected to the lower part of the pressing handle, and the left end of the toothed rod 6 has no teeth, and is inserted into the round hole-shaped groove inside the casing 1 to ensure that it can only move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com