Light convex-rib steel bar

A technology of steel bars and convex ribs, applied to structural elements, building components, building reinforcements, etc., can solve problems such as inability to disperse force, failure of building materials, and damage to square ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the drawings.

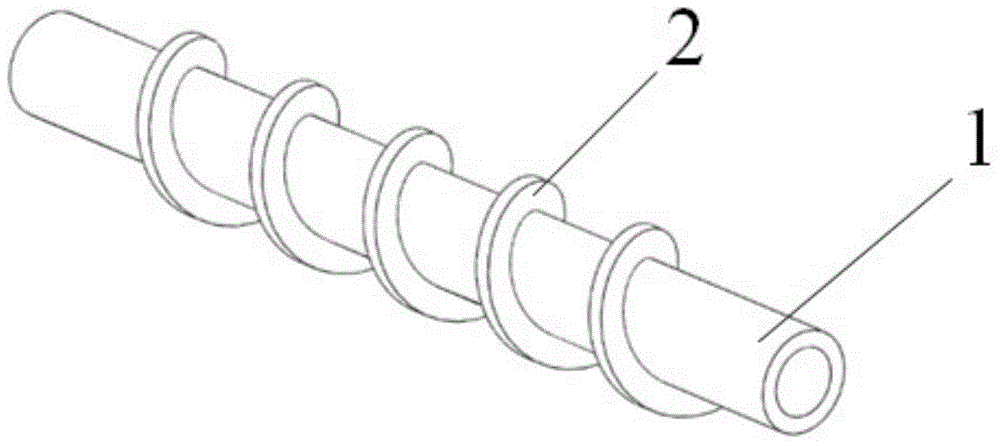

[0011] Such as figure 1 Shown: a light-weight convex-reinforced steel bar, a light-weight convex-reinforced steel bar, includes a rebar body 1 which is a hollow structure and has spiral ribs 2 provided on its outer surface.

[0012] The diameter of the spiral blade of the spiral rib 2 is 2 to 4 times the diameter of the steel body 1.

[0013] Because the spiral rib 2 is a continuous structure, the entire steel bar will be stressed when it is subjected to tensile stress, so that it will take more force in the concrete, and the friction and bite force will be large. When the concrete is subjected to strong bending, etc. At this time, the concrete is not easy to slip, thus increasing the strength of the square rib building materials, so as to achieve the purpose of more effort in the concrete and high friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com